Installation and Configuration Manual 31

Accuracy Considerations

Installation Procedure Accuracy ConsiderationsElectrical ConnectionsIntroduction Installation Procedure Accuracy ConsiderationsElectrical ConnectionsIntroduction Installation Procedure Accuracy ConsiderationsElectrical ConnectionsIntroduction Installation Procedure Accuracy ConsiderationsElectrical ConnectionsIntroduction

Example 1

Example 2

4.2 Calibration (for non-natural gas applications)

The instrument is supplied with its reference chamber empty and thus in an un-calibrated condition.

After installation on site it is necessary to decide what reference chamber pressure to use, and then to

charge and calibrate the instrument as described in Section 2.6.

Some examples of how to calculate these reference chamber pressures are given in Section 4.1.1 and

Section 4.1.2, which show the best pressures for a natural gas and a N

2

/CO

2

mix application.

Once this has been done, the gases to be used for calibration need to be defined. The calibration gases

to be used must be of known specific gravities and substantially represent the properties of the line

gas to be measured (for example, compressibility, viscosity) For example, if measuring a natural gas

which is substantially methane and carbon dioxide, then these two gases in their pure forms or at

defined specific gravities should be used in the calibration.

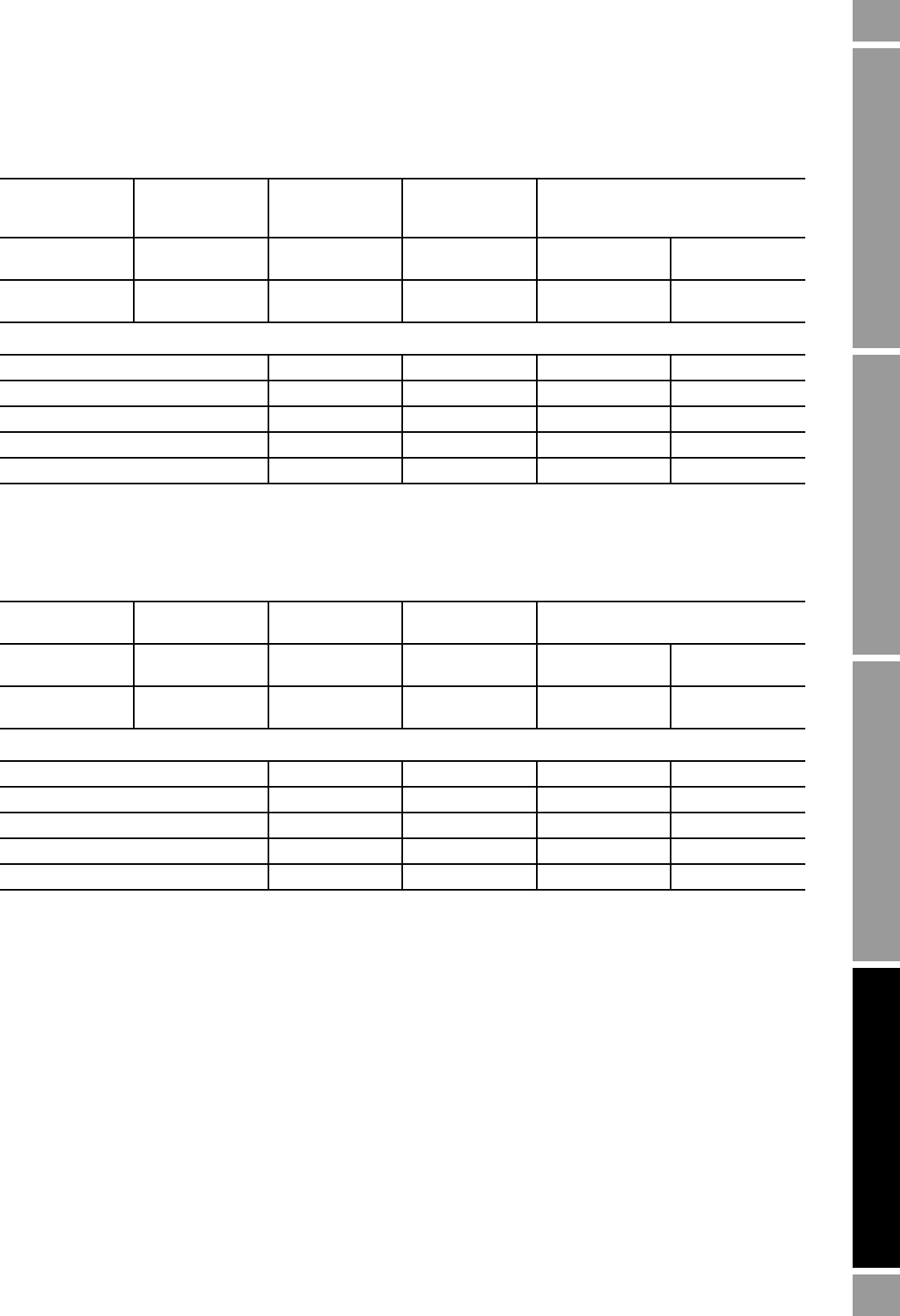

Table 4-2 3098 specific gravity meter control pressure selection (natural gas)

Date: 24th June

1997

Type of gas:

Natural Gas

Specific gravity

range: 0.55 to

0.8

3098 serial no.:

000124

Temperature coefficient of density

meter: –0.0003

kg/m3

/°C

Control pressure

at 20°C

(lb/in

2

abs.)

(bar abs.)

18

1.2

30

2

60

4

100

7

Density range at

20°C

(kg/m

3

) 0.79–1.15 1.32–2.0 2.66–3.8 4.58–6.72

Measurement errors (% of FS specific gravity/°C) due to:

Density meter temperature coefficient –0.026 –0.016 –0.008 –0.004

Gas compressibility of sample gas ±0.0003 ±0.0003 ±0.001 ±0.002

Velocity of sound in sample gas –0.003 –0.003 –0.003 –0.003

Reference chamber/relief valve +0.007 +0.007 +0.007 +0.007

Total error –0.022 –0.012 +0.003 to –0.005 +0.000 to –0.002

Table 4-3 3098 specific gravity meter control pressure selection (N

2

CO

2

mix)

Date: 28th July

1997

Type of gas:

N

2

/CO

2

mix

Specific gravity

range: 1.0 to 1.5

3098 serial no.: Temperature coefficient of density

meter: –0.0003

kg/m3

/°C

Control pressure

at 20°C

(lb/in

2

abs.)

(bar abs.)

18

1.2

30

2

60

2

100

7

Density range at

20°C

kg/m

3

0.79–1.15 1.32–2.0 2.66–3.8 4.58–6.72

Measurement errors (% of FS specific gravity/°C) due to:

Density meter Temperature coefficient –0.026 –0.016 –0.008 –0.004

Gas compressibility of sample gas ±0.0003 ±0.0003 ±0.001 ±0.002

Velocity of sound in sample gas –0.003 –0.003 –0.003 –0.003

Reference chamber/relief valve +0.007 +0.007 +0.007 +0.007

Total error –0.014 –0.006 +0.006 to –0.010 +0.015 to –0.015