– 28 –

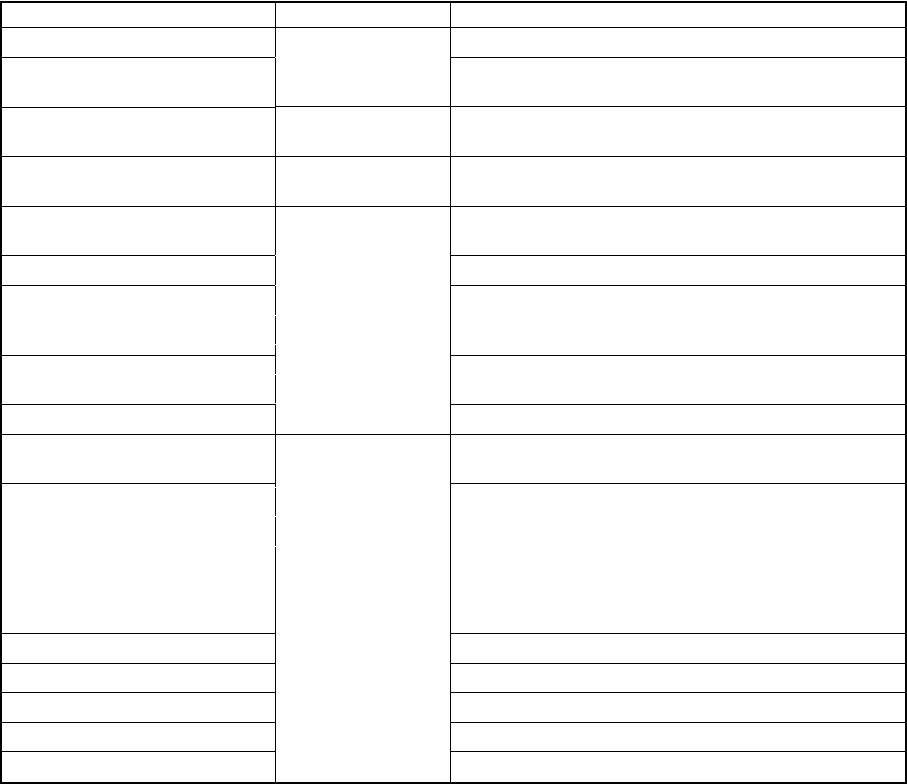

10.2 Periodic maintenance and inspection

Procedure

Refer to section 8.5 to 8.6.

It takes at least 1.5 months to deliver the standard gas. So

the gas should be ordered 2 or 3 months in advance.

Supply water if level is below overflow port.

Replace with new filter paper (stop the aspirator when

exchanging). See 10.5 (3).

Replace these parts if flow rate doesn’t increase because of

adherence of dust. See 10.5 (2).

Replace if clogged.

Check and clean diaphragm. Use valve by turning it to 90°

rightward (replace valve when it is turned once). See 10.5

(4).

Apply soapy water or the like and check for bubbles. Either

retighten or replace packings if necessary.

NO, SO

2

, CO/N

2

of less than 250 ppm. See 10.4.

O-ring requires replacement. Filter element may be reusable

after cleaning. See 10.5 (1).

Replacement (when NO

2

gas concentration is 10 ppm or

less)

Note: Replace once every 8 months when NO gas con-

centration is measured in the setting range of 0 to

200ppm or more at 0.5L/min.

See 10.4.

Replacement of diaphragm

Clean pipes or replace if necessary.

Maintenance/inspection item

Analyzer calibration

Check of standard gas filled

pressure

Water level in upper chamber of

conditioner

Replacement of membrane filter

paper

Inspection and replacement of

conditioner filter, O-ring

Capillary

Check of valve and diaphagm of

aspirator (pump)

Leak test of pressure regulator

Replacement of standard gas

Replacement of gas extractor filter

element, O-rings

Catalyst of NO

2

/NO converter

Replacement of standard gas

Aspirator

Contamination, leak test of piping

Exchange of water in conditioner

Overhaul

Referential frequency

Weekly

Monthly

Every two months

Biannually

Yearly

10.3 Other maintenance and inspection

(1) Space heater and ventilating fan

If the ambient temperature drops below 5°C during winter or the like, then turn ON the space heater.

The ventilating fan should always be left ON.

(2) Blowback of gas extractor (option)

Turn off the aspirator and close the measured gas line before conducting a blowback. Frequent blowback

will cause the temperature of the gas sampler to drop and result in corrosion, so it should be kept to a

minimum.