– 43 –

Note) Pressure control valve is used.

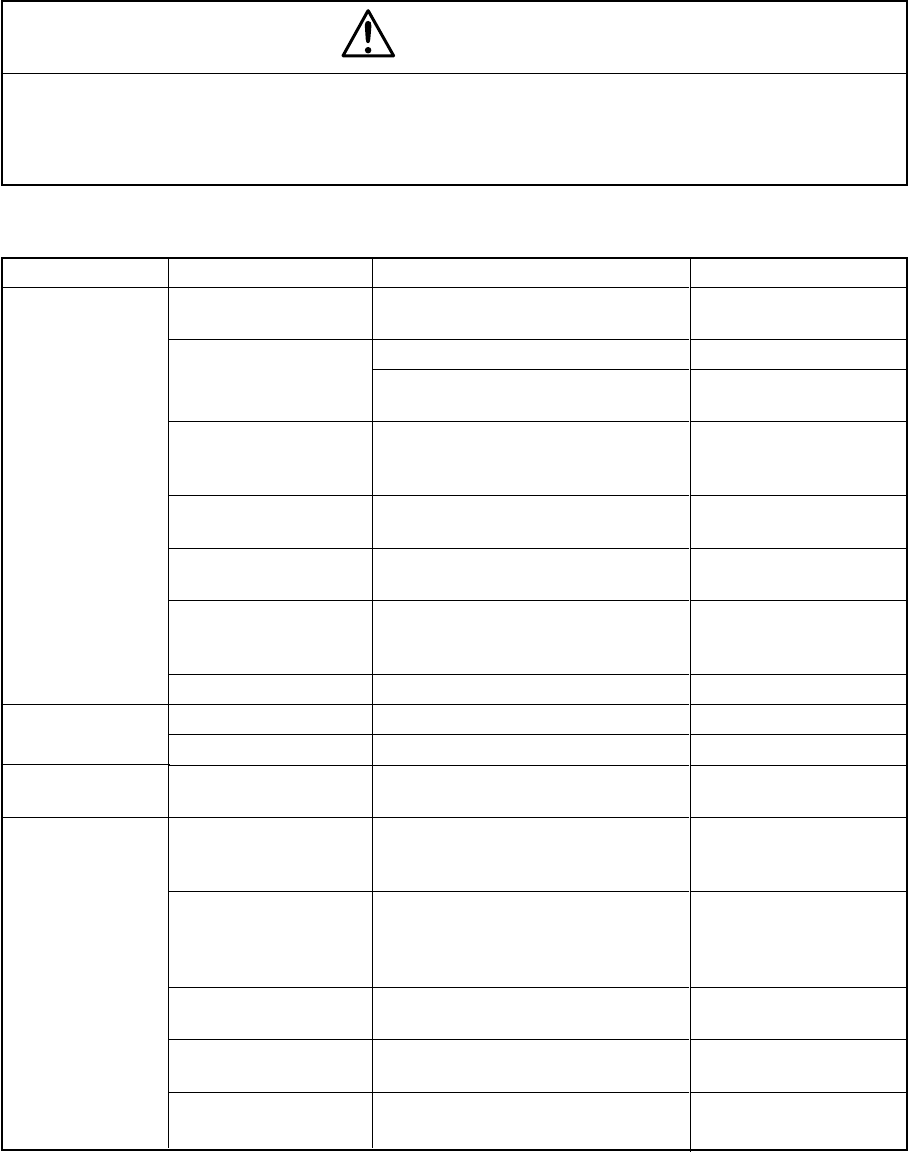

13. TROUBLESHOOTING

Caution

• When trouble cannot be remedied even after following the instruction manual, contact your dealer or

Fuji's service station (serivice engineer). Do not disassemble the device, as it results in electric shocks

or injury.

Trouble

Decrease of sample

gas flow rate

Increase of bubbling

flow rate

Rise of sample gas

flow (Note)

Indicated value is

abnormal.

Check item

Check if filter element is clogged.

Check if aspirator is working normally.

Check for abnormal sound or vibration.

Check if cooler is working normally,

check cooling temperature and check for

clogging of flow path.

Water decreases in lower chamber.

Check for gas leakage in piping after

aspirator or at joints.

Check for accumulation of drainage or

dust in flowmeter. Check adjustment of

needle valve.

Check for bent or clogged piping.

Check for capillary.

Check for deviated joint.

Pressure control valve is clogged.

Check for gas leakage in parts before

aspirator such as secondary coarse filter

holder, piping, joints, etc.

Check if aspirator is normally operating

and sample gas is flowing at set value.

Check if water level is normal.

Check if air is aspirated.

Check for accumulation of drainage in

piping.

Check if SUS pipe is used (for SO

2

analyzer).

Remedy

Clean or replace element.

Clean or replace.

Retighten screws or replace

aspirator.

Clean or replace.

Inject water and check the

capillary (bypass).

Retighten or replace parts.

Clean the flowmeter.

Adjust needle valve.

Replace.

Clean or replace.

Connect properly.

Disassemble and clean.

Retighten or replace parts.

Clean aspirator or replace

parts such as diaphragm or

value

Adjust sample gas flow.

Supply water.

Check primary filter.

Clean, and tilt piping so

drainage does not accumulate.

Change to teflon tube.

Probable location

Filter (primary, second-

ary, tertiary filters)

Diaphragm type aspirator

Electronic gas cooler

Conditioner

Gas leakage

Flowmeter

Piping, capillary

Bypass flow path

Piping

Pressure control valve

Gas leakage

Diaphragm

type aspiration

Conditioner

Dissolution of gas

Sampling pipe

13.1 Troubleshooting of instrument