– 31 –

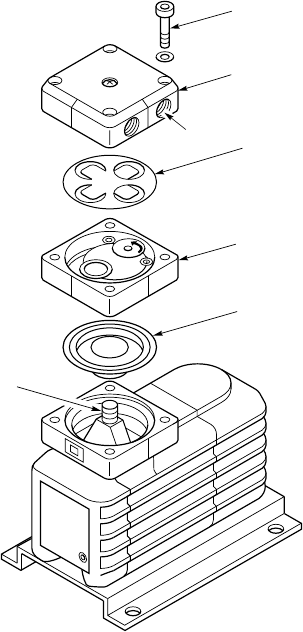

Hex. socket head

cap screw

Cap A

Seat valve

Rc1/8

Cap B

Diaphragm

Arm lot

Fig. 10-4 Exploded view of diaphragm type aspirator

(4) Replacement of the valve and the diaphragm of diaphragm type aspirator

Replace the seat valve (turn 90° in six months and replace annually) and the diaphragm (replace annually)

according to the following procedure.

(a) Turn off the power supply of the aspirator and

remove the inlet and outlet piping connected to

the aspirator.

(b) Remove the four hexagon socket head cap

screws. Then cap A and cap B are separated

and the valve can be removed.

(c) Turn the diaphragm counterclockwise with your

hand and remove it.

(d) Place a new diaphragm to the position and mount

it by turning it clockwise until it stops.

Note) When mounting, check that the dia-

phragm is securely engaged in the

screw section of the arm slot. Other-

wise malfunction may result.

(e) Place the valve on cap B and turn it 90∞. Check

that the notches of cap A and cap B are aligned,

and then tighten the four hexagon socket head

cap screws.

Note) Since complex valve seat is adopted, re-

move the pin on the underside of the

valve from the hole to which the pin has

been inserted and reinsert it to the

other hole.

(f) Turn on the power of the aspirator in the inter-

face module. Check that it does not generate

abnormal sound. Check also with your hand that

the valve is normally operated, that is, air is as-

pirated from the IN side and discharged from

the OUT side. If any abnormality is observed,

repeat the procedure from the beginning.

(g) After checking that the aspirator is normally op-

erated, turn off the power of the aspirator in the

interface module, and return the piping to the

original position.

Note) Do not apply force abruptly to Rc1/8

screw part when returning the piping

to the original position.