– 34 –

(9) Washing the Permapure dryer

The Permapure dryer is used for SO

2

measurement (2000 ppm or more).

The Permapure dryer has no moving sections nor consumable parts. If precautions in using it are suffi-

ciently respected, it can operate without maintenance usually. However, if its element has clogged, for

example, remedy it by the following method.

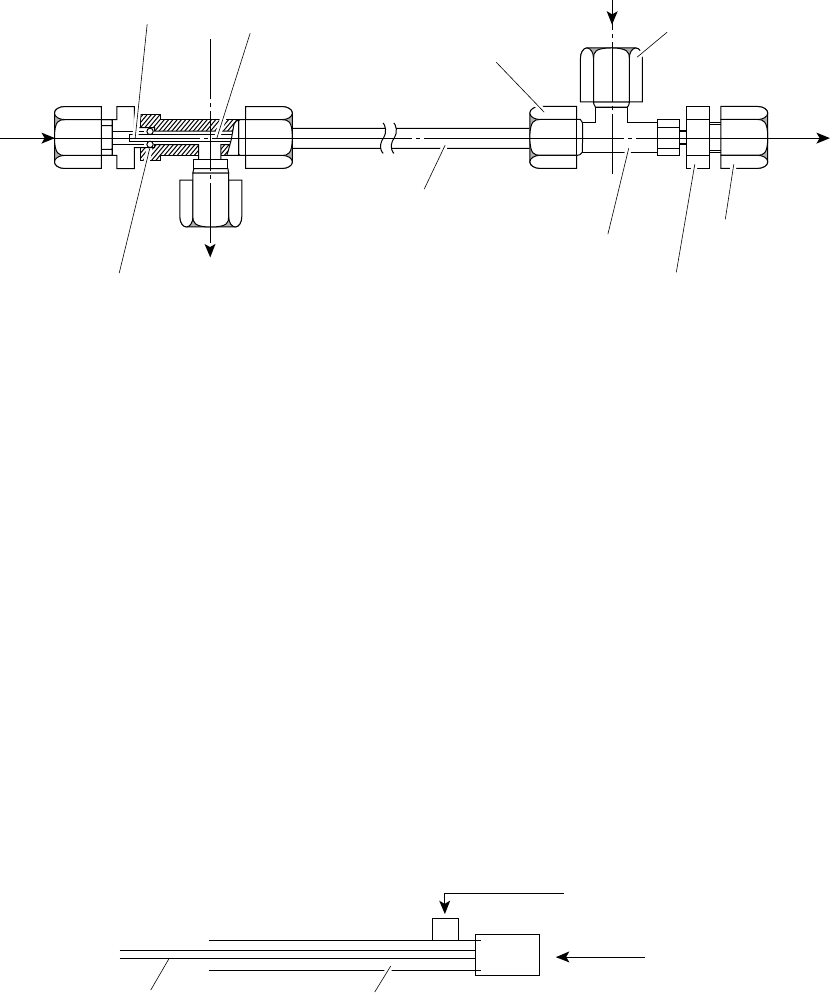

Fig. 10-8 Structure of Permapure dryer

(a) Disassembly

q Remove an O ring presser (one side).

w Loosen a shell joint (one side).

e Push the header inward and remove the tee.

r Loosen the other shell joint and gently pull out the element.

(b) Washing

q Carry out washing with tap water (detergent, alkali solution not allowed).

w On a side, remove the sample joint, cap and tee.

e Through the opposite port and purge port, introduce tap water at 127 kPa or lower pressure and

300 to 500 mN/min of flow rate.

r Carry out washing for longer or shorter time according to the degree of clogging.

If the clogging is slight, approximately 1 hour of washing is enough.

Sample

IN

Header

Element tube

O ring

Purge OUT

Shell

Shell joint

Purge IN

Purge joint

Sample

OUT

Sample joint

O ring presser

Tee

Element tube Permapure dryer

Tap water

Tap water

Fig. 10-9 Washing of Permapure dryer