– 33 –

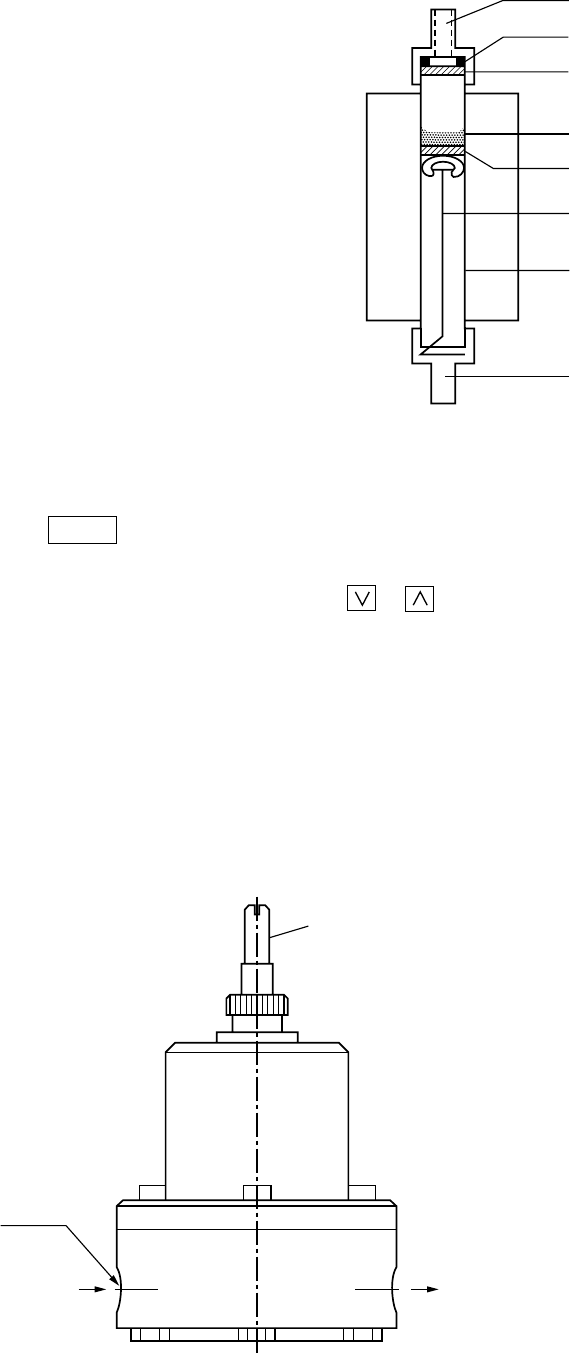

(6) Replacement of NO

2

/NO converter catalyst

(a) Turn off power supply to the converter.

(b) After half an hour, remove q w e, and extract r

upward and downward, respectively. Pay attention

not to suffer a burn. In addition, carefully handle the

ceramic pipe for preventing breakage. When remov-

ing r , e will fall simultaneously. So prepare a

catalyst receiver.

(c) Wind glass wool on the tip of r and insert it from

the bottom together with q. Inject one pack of new

catalyst from the top. Set w e on the top side. (This

step is unnecessary when a membrane filter is pro-

vided at the later stage.)

(d) Connect the pipe, set the temperature controller at

220°C (200°C for NO/CO analyzer), and turn on

power supply.

(7) Setting of temperature controller for NO

2

/NO converter (PXZ4)

(a) When pressing the PV/SV key, display changes over between PV and SV. (Usually, PV (Process

Variable) display is set).

(b) Under SV (Set Value) display, set 220°C by pressing the or key and determine it by the ENT

key. (200°C need be set for NO/CO analyzer.)

(c) Parameter need not be set because they have been factory-set.

(d) The temperature controller controls converter temperature through the SSR relay.

(8) Setting of pressure control valve

The pressure control valve has been set the discharge about 2 N/min. of sample gas together with drain,

when the pressure at the inlet is about 50 kPa. The set pressure increases with a right turn of the setting knob

and decreases with a left turn.

Do not turn the setting knob unless the sample flow needs to be changed.

Connection

rubber

Filter

Ring

Filter

Fastener

Ceramic

pipe

Connection

rubber

Catalyst

q

w

e

r

e

t

y

q

Fig. 10-6 Structure of NO

2

/NO converter

IN

OUT

Setting knob

2-Rc1/4

Sample

Fig. 10-7 External appearance of pressure control valve