Model G0757Z (Mfd. Since 02/15)

-37-

Using Spindle

Downfeed Controls

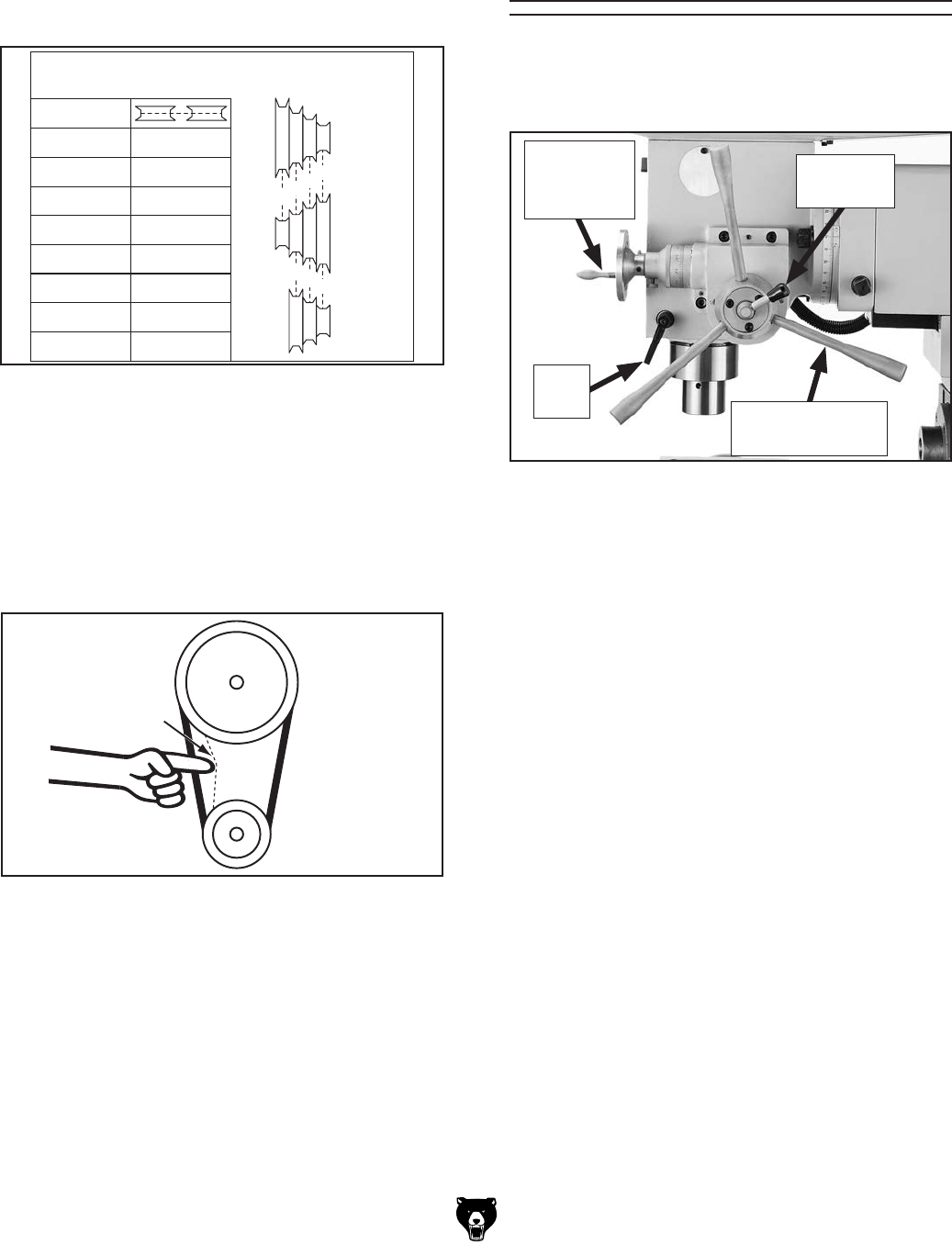

Use Figure 39 and the descriptions below to

understand the downfeed components that con-

trol the 5" spindle downfeed travel.

Figure 39. Spindle downfeed controls.

Fine

Downfeed

Handwheel

Coarse

Downfeed Lever

Selection

Lever

Quill

Lock

Coarse Downfeed Levers: Manually control

downfeed travel in a rapid manner. Generally

used for drilling operations. Spindle automatically

returns to top position when pressure is released

from the handle.

Fine Downfeed Handwheel: Manually controls

downfeed travel in a slow, precise manner. Unlike

coarse downfeed, spindle does not automatically

retract. The attached graduated dial has incre

-

ments of 0.001" with one full revolution represent-

ing 0.100" of travel. Generally used for milling

o

perations.

Selection Lever: When tightened, enables the

fine downfeed handwheel; conversely, when loos

-

ened enables the coarse downfeed levers.

Q

uill Lock: Secures the quill in place for increased

stability during milling operations.

5. Arrange V-belts for desired horizontal spindle

speed (see Figure 37).

Note: Horizontal spindle speed chart shown

below is also on side of column.

Vertical Spindle Speeds

285 860

1320

1720

2300

D – E D – G

A – F

A – G

B – G

C – E

D – F

B – E

C – F

390

490

585

665

RPM RPM

A

B

C

D

E

F

G

Spindle Motor

Upper

Motor

Horizontal Spindle Speeds

72 A – G

B – G

C – G

A – F

170

210

240

RPM

A – E290

B – F550

C – E830

B – D1300

A

E

F

G

B

C

D

Figure 37. Horizontal spindle speed chart.

6. Apply pressure on lower idler pulley to left as

you tighten tension thumbwheel.

Note: There is proper V-belt tension when

approximately

1

⁄4" –

1

⁄2" deflection is achieved

by applying moderate pressure midway

between pulleys as shown in Figure 38.

7. Retighten hex nut behind lower idler pulley

bracket.

8. Close and latch V-belt cover.

Pulley

1

⁄

4

"–

1

⁄

2

"

Deflection

Pulley

Figure 38. Checking V-belt tension.