-52-

Model G0757Z (Mfd. Since 02/15)

Changing Coolant

Tools Needed Qty

Hex Wrench 5mm .............................................. 1

Catch Pan .......................................................... 1

Empty Bucket 5-Gal. ......................................... 1

Rubber Hose (optional) ..................................... 1

Goggles .......................................... 1 Per Person

Gloves ............................................ 1 Per Person

Respirator ....................................... 1 Per Person

New Coolant ..........Approx. 2 Gallons (7.5 Liters)

Disposable Shop Rags ...................... As Needed

To change coolant:

1. Put on personal protective equipment.

2. Place catch pan on table, position coolant

nozzle into pan, then use coolant pump to

drain reservoir.

Note: When catch pan is near full, empty it

into a 5 gallon bucket, then repeat process

until reservoir is empty.

Tip: Alternately, slide a rubber hose onto

coolant nozzle and point it 5 gallon bucket.

3. DISCONNECT MACHINE FROM POWER!

4. Clean away debris from coolant return screen

and surrounding area, then remove screen

from base.

5. Thoroughly clean out reservoir. Make sure

interior is dry before adding new coolant.

Note: Use a shop vacuum and a cleaning

solution that is compatible with type of cool-

ant. For instance, if you are using a water-

base coolant, then use a water-base cleaning

solvent. Also, use magnets to remove any

metal chips left behind.

6. When reservoir is clean and dry, fill reservoir

with new coolant through hole in the base left

by return screen.

Tip: Place a couple of magnets inside res-

ervoir under return screen to collect metal

particles and keep them out of coolant pump.

7. Re-install return screen before resuming mill-

ing operations.

V-Belt Service

During the first 16 hours of use, the V-belts may

stretch slightly and seat into the pulleys. It is impor-

tant to check and adjust them to compensate for

this initial wear. Check the tension thereafter on a

regular basis. If belts become excessively worn or

damaged, replace them.

All V-belts can be replaced by releasing the ten-

sion and rolling them off the pulleys, then rolling

the new belts back onto the pulleys.

Tensioning Lower Horizontal Spindle

V-Belts

Tools Needed Qty

Open-End Wrench 24mm .................................. 1

Dead Blow Hammer .......................................... 1

Hex Wrench 8mm .............................................. 1

To tension lower horizontal spindle V-belts:

1. DISCONNECT MACHINE FROM POWER!

2. Open column rear cover to gain access to

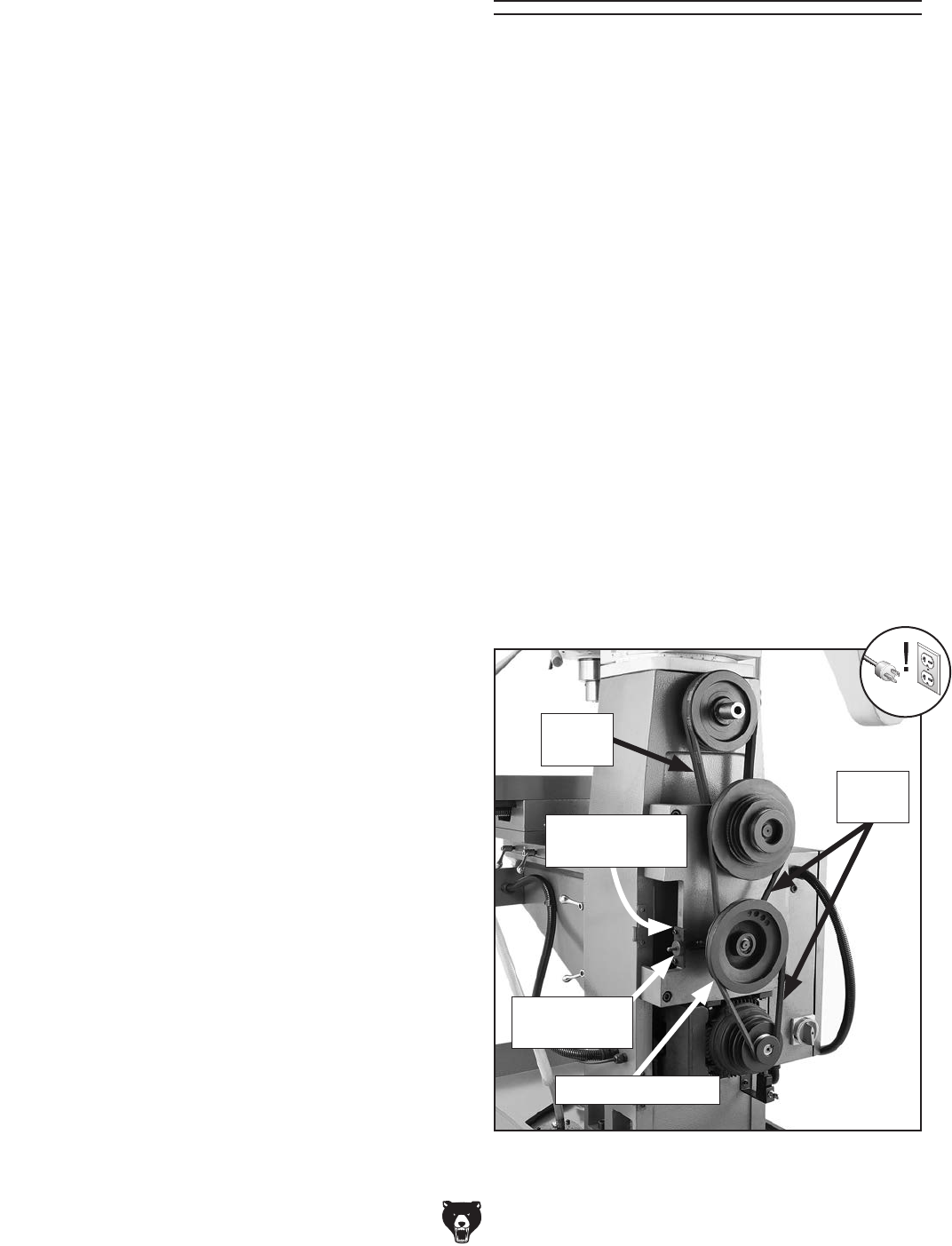

horizontal spindle V-belts and pulleys, as

shown in Figure 73.

Figure 73. Horizontal spindle V-belts and pulleys

(cover removed for photo clarity).

Hex Nut

Behind Bracket

Tension

Thumbwheel

Lower Idler Pulley

Lower

V-Belts

Upper

V-Belts