-60-

Model G0757Z (Mfd. Since 02/15)

9. Rotate spindle so indicator point rests on par-

allel block, as illustrated in Figure 79, then

zero dial.

10. Rotate spindle so that indicator point rests on

other end of block in same manner, then read

dial.

— If indicator dial still reads zero or is within

the acceptable variance, the spindle is

precisely perpendicular to table in both

X- and Y-axes, and tramming procedure

is complete.

— If indicator dial has moved from zero

beyond acceptable variance, you will need

to compensate for that amount by tilting

head forward or backward. Repeat Steps

9–10 until you are satisfied with spindle

axis alignment along table Y-axis.

Note: Keep one of the tilt lock bolts just snug

so the head does not move loosely while you

adjust it. Remember to tighten all the tilt lock

bolts after adjusting the head.

Adjusting Leadscrew

Backlash

Leadscrew backlash is the amount of free play

movement in the leadscrew (when the leadscrew

moves but the table does not) after changing the

direction of rotation.

A leadscrew must have a certain amount of back-

lash to rotate easily, but over time, it increases

with wear. Generally, 0.005"–0.010" leadscrew

backlash is acceptable to ensure smooth move-

ment and reduce the risk of premature thread

wear.

The X-axis leadscrew backlash is adjusted using

a long 4mm hex wrench to tighten/loosen the cap

screws on the leadscrew nut. This adjusts the force

the leadscrew nut exerts on the leadscrew threads.

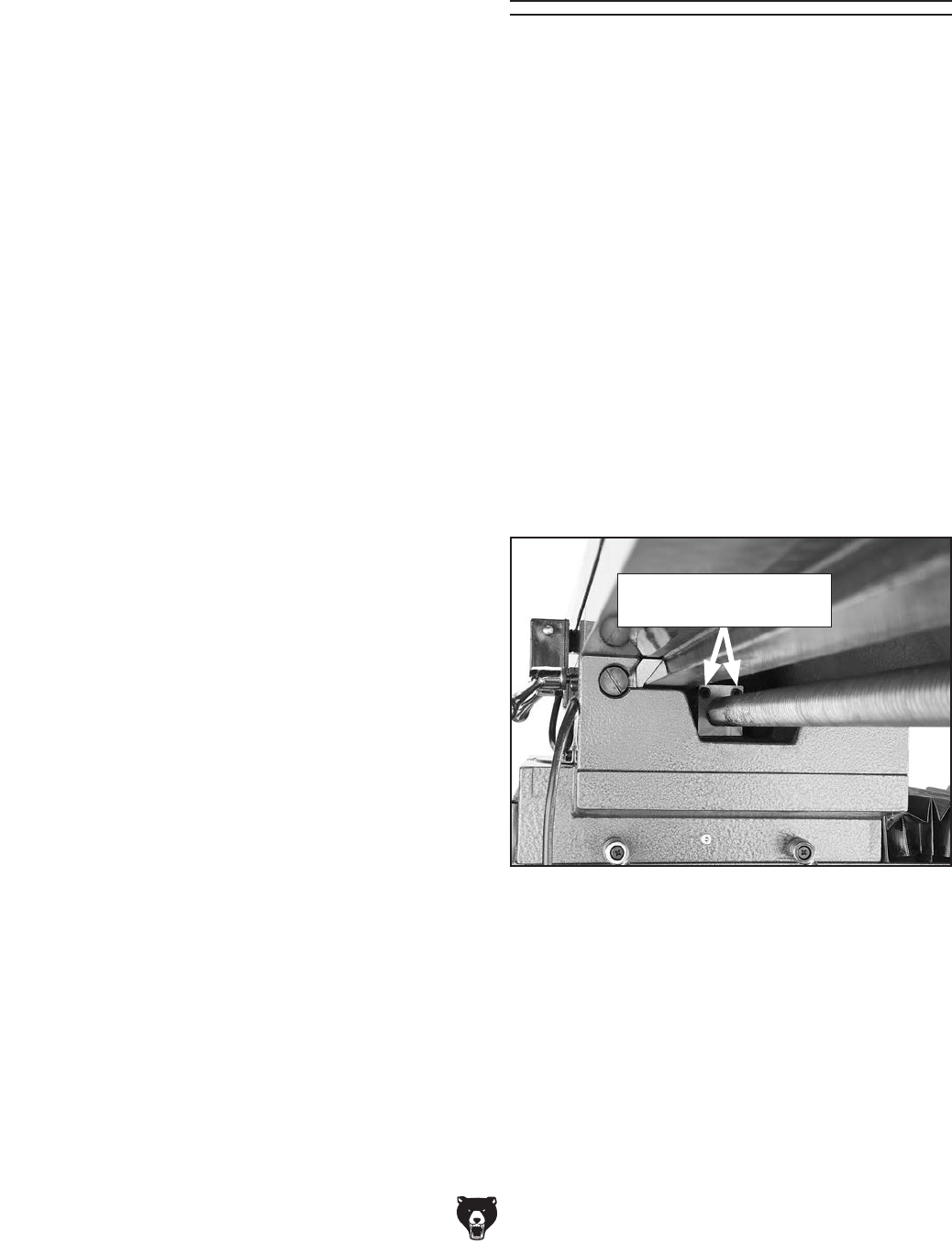

The X-axis leadscrew nut shown in Figure 80 is

accessed from underneath the right side of the

table.

Figure 80. Location of X-axis leadscrew nut cap

screws for adjusting backlash.

X-Axis Leadscrew Nut

Cap Screws