-44-

Model G0757Z (Mfd. Since 02/15)

SECTION 6: MAINTENANCE

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Metal chips and other debris left on the machine

will invite oxidation and a gummy residue build-up

around the moving parts. Use a brush and shop

vacuum to remove chips and debris from the

working surfaces of the mill. Never blow off the

mill with compressed air, as this will force metal

chips deep into the mechanisms and may cause

injury to yourself or bystanders.

Remove any rust build-up from unpainted cast

iron surfaces of your mill and treat them with a

non-staining lubricant after cleaning.

Keep unpainted cast iron surfaces rust-free

with regular applications of products like G96

®

Gun Treatment, SLIPIT

®

, or Boeshield

®

T-9 (see

Figure 57 and the Grizzly catalog or website).

Cleaning &

Protecting

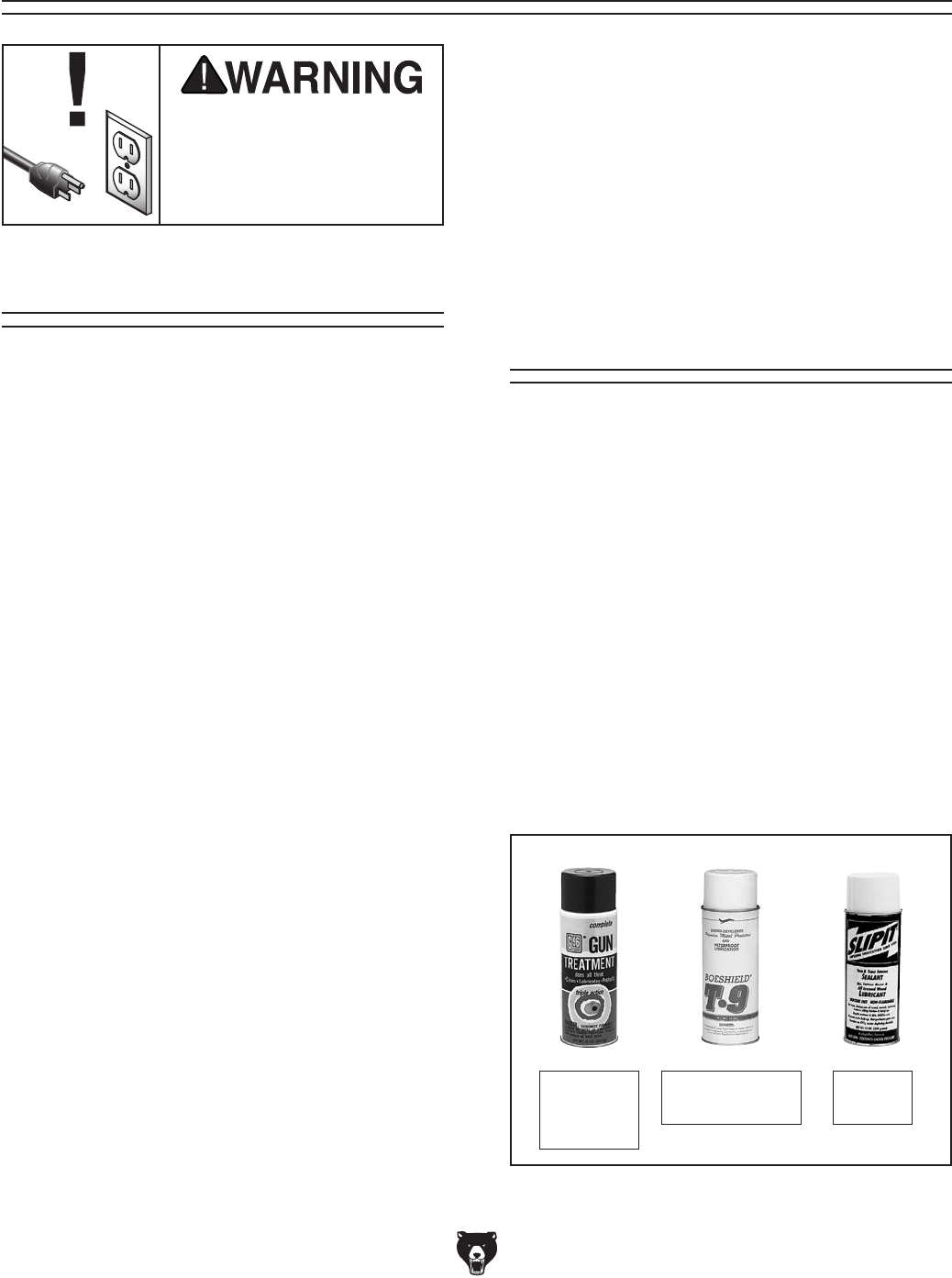

Figure 57. Products to clean and protect

unpainted cast iron surfaces.

H3788

G96

®

Gun

Treatment

G2870

Boeshield

®

T-9

G5563

SLIPIT

®

Regular maintenance will help ensure proper

care of the equipment. We strongly recommend

that all operators make a habit of following the

maintenance procedures found in this section.

For optimum performance from this machine, this

maintenance schedule must be strictly followed.

Ongoing

To maintain a low risk of injury and proper

machine operation, if you ever observe any of the

items below, shut the machine down immediately,

disconnect it from power, and fix the problem

before continuing operations.

• Loose mounting bolts or fasteners.

• Worn, frayed, cracked, or damaged wires.

• E-STOP button not working correctly.

• Worn or loose V-belts (see Page 52).

• Missing or open belt guards/door.

• Coolant not flowing correctly.

• Any other unsafe condition.

Before Beginning Operations

• Press the E-STOP button on the control

panel to prevent high-speed spindle startup

when connected to power.

• Make sure the X-axis power feed is turned

OFF to prevent unintentional table movement

when connected to power.

• Check the coolant reservoir in the base. Fill it

or clean it out if necessary (see Page 51).

• Perform all required lubrication tasks (see

Page 45).

• Check table movement in all three axes for

loose/tight gibs. Adjust the gibs if necessary.

Daily, After Operations

• Push the E-STOP button, turn the mas-

ter power switch OFF, and disconnect the

machine from power.

• Vacuum/clean all chips and swarf from table,

slides, and base.

• Wipe down all unpainted or machined sur-

faces with a high-quality rust preventative.