Model G0757Z (Mfd. Since 02/15)

-47-

Ball Oilers

Oil Type ......Model T23963 or ISO 32 Equivalent

Oil Amount .........................................1–2 Pumps

Lubrication Frequency ...... 4–8 Hrs. of Operation

Proper lubrication of ball oilers is done with

a pump-type oil can that has a cone tip (see

Page 39 for offerings from Grizzly). We do not

recommend using metal needle or lance tips, as

they can push the ball too far into the oiler, break

the spring seat, and lodge the ball in the oil galley.

Push the tip of the oil can nozzle against the ball

oiler to create a hydraulic seal, then pump the oil

can once or twice. If you see sludge and contami-

nants coming out of the lubrication area, continue

pumping the oil can until the oil runs clear. Move

the components through the entire path of travel a

few times to distribute the oil. When finished, wipe

away the excess oil.

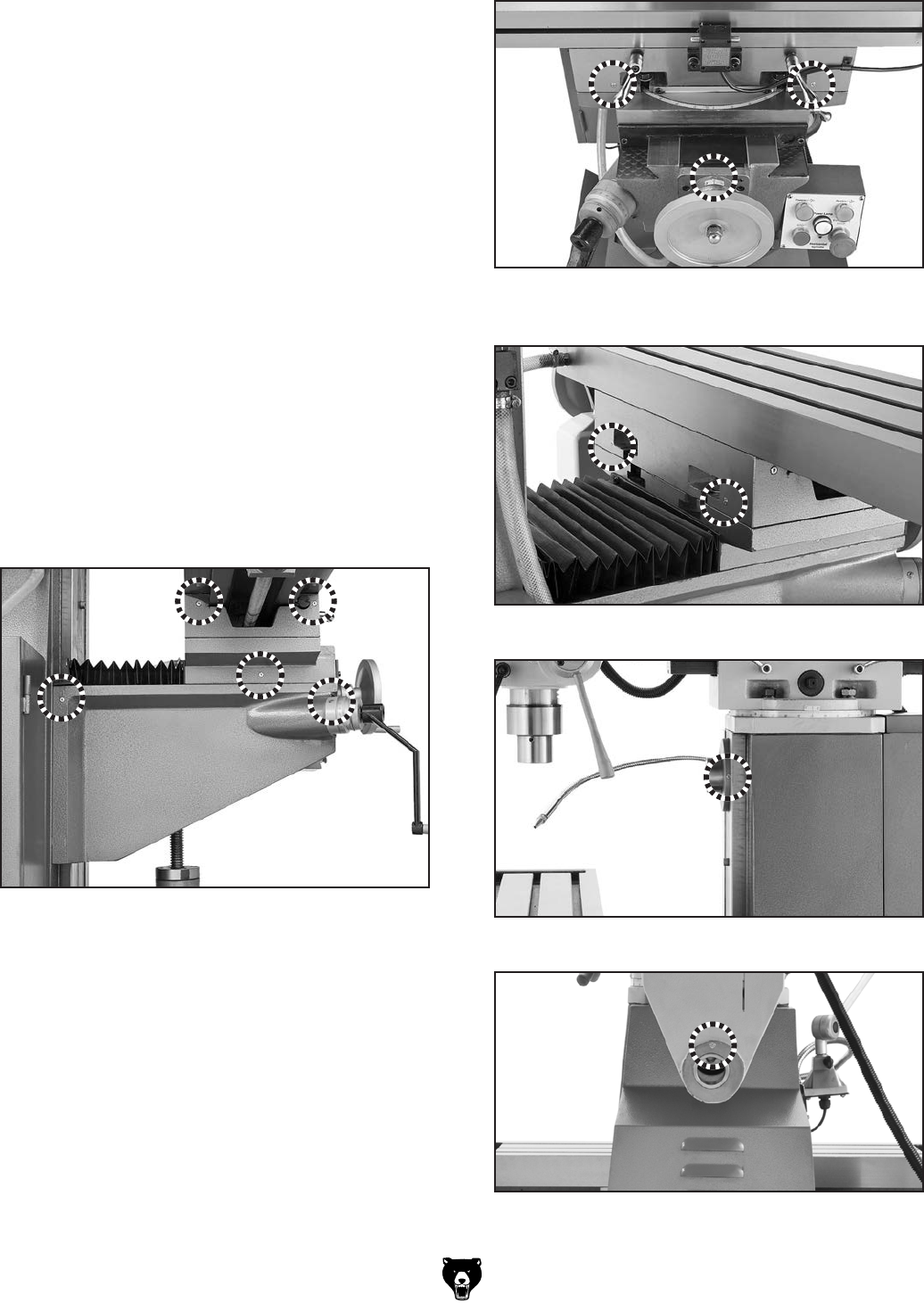

Use Figures 60–64 to locate the 13 ball oilers on

the Model G0757Z.

Figure 60. Ball oilers on the side of the knee

and Z-axis crank ball oiler.

Note: There is a single ball oiler duplicated on the

opposite side of the knee.

Figure 61. Front saddle and Y-axis handwheel

ball oilers.

Figure 62. Rear saddle ball oilers.

Figure 63. Horizontal spindle ball oiler.

Figure 64. Horizontal spindle arbor support ball

oiler.