-48-

Model G0757Z (Mfd. Since 02/15)

Vertical Spindle Bearings

Oil Type ......Model T23963 or ISO 32 Equivalent

Oil Amount .........................................1–2 Pumps

Lubrication Frequency ...... 4–8 Hrs. of Operation

To lubricate vertical spindle bearings:

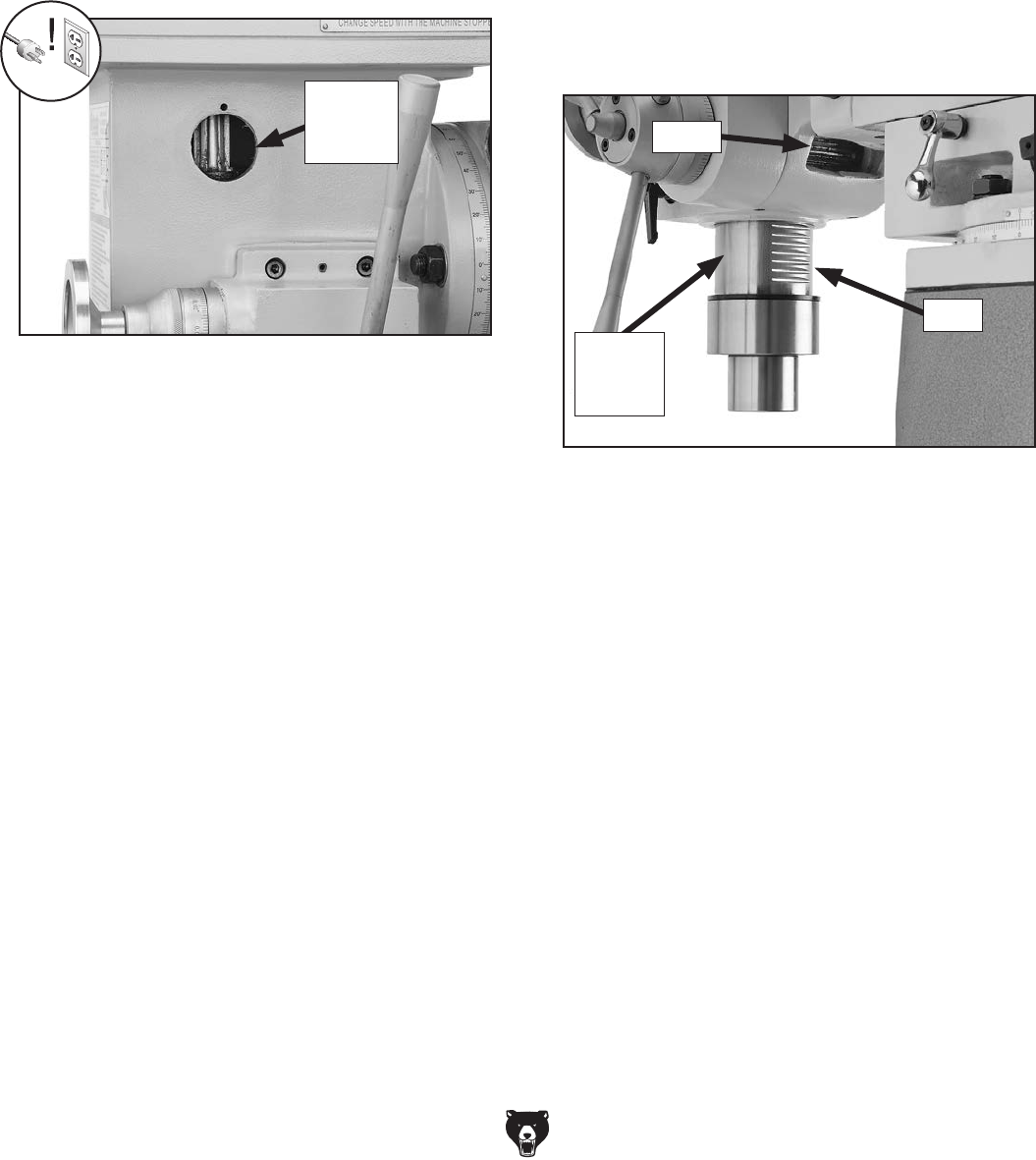

1. Remove circular cover on right side of head

to expose vertical spindle spline (see Figure

65).

Quill Exterior

Oil Type ......Model T23962 or ISO 68 Equivalent

Oil Amount ............................................Thin Coat

Lubrication Frequency ...... 4–8 Hrs. of Operation

Fully extend the spindle to expose the quill (see

Figure 66), then use an oily shop rag to apply a

thin coat of lubricant to the smooth surface of the

quill.

Note: If you remove any of the grease from the

teeth of the quill rack, replace it as instructed

below.

2. Raise spindle until you can see top of quill.

3. Add 1–2 pumps from an oil can between

spindle spline and top of quill.

4. Replace circular cover and run vertical spin-

dle for a few minutes to distribute oil in

bearings.

Quill Rack & Pinion

Grease Type ......... NLGI#2 Grease or Equivalent

Oil Amount ............................................Thin Coat

Lubrication Frequency .........40 Hrs. of Operation

Fully extend the spindle to expose the quill rack

(see Figure 66), then use mineral spirits, shop

rags, and a brush to clean the old grease from the

teeth of the rack and pinion.

When dry, use a brush to apply a thin coat of

grease to the teeth, then move the quill up and

down several times to evenly distribute the grease.

Figure 65. Vertical spindle spline exposed for

lubrication.

Spindle

Spline

Exposed

Figure 66. Quill lubrication points.

Pinion

Rack

Quill

Smooth

Surface