Cabling and connections 33(96)

6

6.1.3 Installation instructions

1

Before starting the installation, check that none of the components of the

frequency converter is live.

2

The NXL frequency converter types MF2 and MF3 shall be installed inside

switchgear, separate cubicle or electrical room because of the protection class

IP20 and the fact that the cable terminals are not protected.

3

Place the motor cables sufficiently far from other cables:

Avoid placing

the motor cables in long parallel lines with other cables

If the motor cables run in parallel with other cables, note the

minimum

distances

between the motor cables and other cables given in table

below.

The given distances also apply between the motor cables and signal

cables of other systems.

The maximum length of the motor cables is 30 m (MF2-MF3), 50 m

(MF4) and 300 m (MF5 – MF6)

.

The

motor cables should cross

other cables at an angle of 90 degrees.

4

If

cable insulation checks

are needed, see Chapter 6.1.5.

5

Connect the cables:

Strip the motor and mains cables

as advised in Table 6-4 and Figure

6-5.

Connect the mains, motor and control cables

into their respective

terminals (see e.g.).

For Information on

cable installation according to UL regulations

see

Chapter 6.1.4.

Make sure

that the control cable wires do not come in contact with the

electronic components of the unit.

If an

external brake resistor

(option) is used, connect its cable to the

appropriate terminal.

Check the connection

of the earth cable to the motor and the frequency

converter terminals marked with .

Connect the

separate shield of the motor cable

to the earth plate of the

frequency converter, motor and the supply centre.

Ensure

that the control cables or the cables of the unit are

not trapped

between the frame and the protection plate.

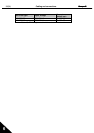

Distance

between cables

[m]

Shielded

cable

[m]

0.3

≤

20

1.0

≤

50