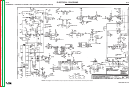

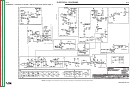

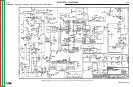

ELECTRICAL DIAGRAMS

G-8

PRECISION TIG 275

®®

SCHEMATIC - ENTIRE MACHINE - ABOVE CODE 11000 (G5691)

EN-170

S

O

L

ID

E

D

G

E

ENGINEERING CONTROLLED

MANUFACTURER:

No

RELEASED FROM X A.02

G5691

PRECISION TIG

MACHINE SCHEMATIC

NONE

G4075

bburkhart

burkhart

-

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

NA CRM38261

1

PAGE ___ OF ___

1

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

THE INFORMATION ON THIS

PRINT IS FOR REFERENCE

ONLY. COMPONENTS AND

CIRCUITRY MAY BE DIFFERENT

FROM AN ACTUAL MACHINE.

7-27-2007

CHANGE DETAIL:

IF PRINTED

@ A1 SIZE

UNITS:

NONE

G5691

LEAD COLOR CODE:

B-BLACK OR GRAY

G-GREEN

O-ORANGE

R-RED OR PINK

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1

2

6

712

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

SCR4

SCR1

SCR3

SCR2

MAIN

RECTIFIER

D1

OUTPUT

INDUCTOR

AC

DC

DC

DC

DC

AC

AC

AC

++

-

-

RECEPTACLE

R1

POLARITY

SWITCH

SHUNT

FRONT

WORK

SV1

GAS

SOLENOID

CB1

115V/15A

FAN

X3

X4

250

SEE NOTE A

MAIN

TRANSFORMER

RECONNECT

PANEL

X2

X1

H1

H2

H3

H4

L2

L1

ELECTRICAL SYMBOLS PER E1537

+

-

TM

CLOSED

IN DC

REMOTE

HIGH FREQ.

TRANSFORMER

115 V

RECEPTACLE

3KV

.0047/

400A/200mV

S2

50/100W

OPTIONAL AMPTROL REMOTE

CONTROL AND ARC START SWITCH

T2

S

F

C6

.0015/

12KV

50/60HZ MACHINES ONLY

C4

C5

C1 C3

SPARK

GAP

R5

200/100W

LEAD #250 CONNECTS TO "HIGH" TERMINAL ON

FROM MAIN TRANSFORMER (T1)

RECONNECT PANEL, ALONG WITH CORRECT LEAD

208/230/460

LEAD #250 CONNECTS TO THE H5 LEAD OF

THE MAIN TRANSFORMER (T1)

230/460/575

LEAD #250 CONNECTS TO THE "MID" TERMINAL

ON THE RECONNECT PANEL, ALONG WITH CORRECT

LEAD FROM THE MAIN TRANSFORMER (T1)

NOTE A:

CONNECTS ACCORDING TO THE INPUT VOLTAGE

LEAD #250 FROM POWER FACTOR CAPACITORS

C7

15/250V

220V 2A

RECEPTACLE

CB2

220V/5A

H5

HIGH

VOLTAGE

TRANSFORMER

H1

220/380/415

L1

L2

L3

C2

T3

240

238A

PRESENT ONLY ON

PRECISION TIG 375

R13

HI-FREQ INTENSITY

REAR

ELECTRODE

(STICK WELDING)

(TIG WELDING)

HOLDING RESISTOR

COOLER

RECEPTACLE

(BOTTOM of plug)

(TOP of plug)

231A

231B

231A

231D

FAN

2

3

1

E

231F

260A

PRECISION

TIG 375 ONLY

X13

R14

CR2

C8

C9

.22/400V

.22/400V

CR4

233B

234

(12VDC)

COOLER RELAY

233

232

231

236B

237

238

239

225A 228

DC

+

DC

-

DC

+

DC

-

224

CR3

226

227A

CR3

223

227

225

CR2

CR3

258

256

257

CR3

CR2

255

231C

AC & DC STICK OCV BOOST CIRCUIT,

PRESENT ONLY ON PRECISION TIG 375

OCV BOOST

RECTIFIER

AC

BOOST

DC

BOOST

2

7

1

A

229

229A

268

R8B

R7D

BACKGROUND CIRCUIT

ENABLED IN BOTH TIG

& STICK, AC & DC

X5

X6

63.5V

269

270

BACKGND AC IN

271

1J4

5J4

G1

G2

G3

G4

218

217

216

220

SCR1,SCR2 CATHODE

SCR3 CATHODE

SCR4 CATHODE

SCR3,SCR4 ANODE

SCR1 GATE

SCR2 GATE

SCR3 GATE

SCR4 GATE

216

G4

G1

G2

G3

220

217

218

1J12

5J12

115VAC IN

AC STICK

115VAC IN

DC STICK

2J4

4J4

9J4

6J4

10J4

7J4

BACKGND AC OUT

BACKGND FILTER CAP., POS

BACKGND FILTER CAP., NEG

3J11

11J11

2J11

10J11

BACKGND

RECTIFIER

X14

231B

231E

236

TOROID

TOROID

HI-FREQ (115VAC)

GAS (115VAC)

FAN (115VAC)

235

260

265

266

252

253

MICRO SWITCH ON POLARITY SWITCH

VOLT FEEDBACK, ELECTRODE

VOLT FEEDBACK, WORK

265

266

252

253

MICRO SWITCH ON POLARITY SWITCH

TOROID

6J11

12J11

1J11

9J11

POWER SWITCH

MICRO SWITCH

215

212

212

215

PRECISION TIG 375

ONLY

PRECISION TIG 375

ONLY

PRECISION TIG 275 ONLY

262

263

214

213

TSTAT

TSTAT

COOLER, +12VDC IN TIG WELDING

COOLER, COMMON

262

263

5J11

13J11

4J11

14J11

TOROID

233A

235

233A

260

233A

115VAC IN

6J12

3J12

2J12

4J12

TOROID

X7

X8

X9

X10

20VAC

CONTROL BOARD SUPPLY

20VAC

TRIGGER CIRCUIT

8J11

16J11

7J11

15J11

209

210

201

204

AUX. WINDINGS OF

MAIN TRANSFORMER T1

PRIMARY TSTAT

SECONDARY TSTAT

(OF MAIN TRANSFORMER T1)

3J4

8J4

X

X

TOROID

R 222(-)

W 221(+)

W 221

R 222

SHUNT (+)

SHUNT (-)

1J6

2J6

TOROID

1J13

2J13

3J13

4J13

5J13

6J13

343

344

345

346

TOROID

4

3

2

1

344

345

343

METER

R1

311

312

313

+10V

COM

PRESET (0 - 10V)

1J9

2J9

3J9

MAX

OUTPUT

CW

MIN

OUTPUT

CW

313B

314

320

MIN OUTPUT (0 - 1.5V)

+1.5V

R4

CW

CW

R2

CW

BALANCE

313C

311A

322

12J9

4J9

10J9

BALANCE (0 - 10V)

316

317

LOCAL

REMOTE

316

317

6J9

7J9

+15V

REMOTE (+15V)

CW

R3

CW

A

MIN A

VOLT

DISPLAY SWITCH

316B

316C

321

315

319

STICK

TIG

MODE SWITCH

316A

313A

321

315

319

318

11J9

5J9

9J9

8J9

STICK (+15V)

POSTFLOW (0 - 15V)

TOROID

STICK

AUTO BALANCE

REMOTE

(RED)

(GREEN)

(GREEN)

GAS

(GREEN)

THERMAL

(YELLOW)

B

W

B

W

B

W

B W

331

332

333

B

W

334

335

331

331

332

332

333

333

334

334

335

335

B

W

B

W

B

W

B

W

B

W

6J10

1J10

7J10

2J10

8J10

3J10

9J10

4J10

10J10

5J10

TOROID

LED LIGHTS

R9

CW

CW

R10

FREQUENCY

ON TIME

CW

R12

DOWN SLOPE

401C

401D

402

403

405

406

407

CW

R11

BACK GROUND

B

W

PULSE

OFF

TRIGGER

4-STEP

2-STEP

401B

404

401A

411

401

408

409

410

FREQ. (.08 - 15V)

402

403

405

406

407

PULSE

(GREEN)

ON TIME (1-15V)

DOWNSLOPE

2J1

3J1

5J1

6J1

7J1

404

401

411

W

PULSE ON (15V)

+15V

2-STEP (15V)

PULSE LED

8J1

9J1

10J1

4J1

1J1

11J1

12J1

TOROID

A

B

C

D

E

F

U

N

R

B

W

10K

PROTECTION

PCB

4J22

1J22

2J22

3J22

6J22

5J22

A

B

C

D

E

F

2J5

3J5

4J5

5J5

7J5

6J5

8J5

1J5

TOROID

TOROID

2J23

3J23

4J23

5J23

7J23

1J23

2J5A

3J5A

4J5A

5J5A

7J5A

1J5A

6J5A

8J5A

MOVE THIS PLUG FROM

J5 TO J5A FOR ROBOTIC INTERFACE

ADVANCED CONTROL

PCB

(OPTIONAL ON PT275)

J2

J3

1

23

4

WHEN ADVANCED CONTROL

PCB IS NOT INSTALLED

DISCONNECT FOR

DOUBLE PRE/POST FLOW

DIP SWITCH

(ADVANCED FEATURES

SELECTION)

HOT START TRIMMER

ARC FORCE TRIMMER

( SCHEMATIC G4762-X)

(SCHEMATIC G4760-X)

(SCHEMATIC S22530)

BYPASS/STABILIZER

PCB

(SCHEMATIC M16115)

ADVANCED CONTROL PANEL (OPTIONAL ON PT275)

1J7

3J7

2J7

5J7

4J7

6J7

PT375 use ONLY

CONTROL PCB

POST FLOW

8/300W

10K

10K

10K

10K

10K

10K

10K

10K

LOW

MID

HIGH

SV2

SOLENOID

OPTIONAL

WATER

PLUGGED TO

COOLER RECEPTACLE

(SHOWN IN REMOTE)

(SHOWN IN STICK)

DISPLAY VOLT (+15V)

DISPLAY MIN A (+15V)

313A

318

CONTROL PANEL

(SHOWN IN 2-STEP)

MAX

WIPER

MIN

PT375 ONLY

N.O.

N.C.

115VAC

105VAC

3/25W

(115VAC)

TOP FAN

BOTTOM FAN

(115VAC)

c.c. w

(115VAC)

c.w.

(115VAC)

5.5 OHMS

TYP.

14.5 KOHMS

TYP.

12.5 OHM TYP.

12.5 OHM TYP.

KIT

ELECTRODE

T1

T1

T1

T1

223

HI-FREQ CIRCUIT

460/575

LEAD #250 CONNECTS TO THE "LOW" TERMINAL

ON THE RECONNECT PANEL, ALONG WITH CORRECT

LEAD FROM THE MAIN TRANSFORMER (T1)

POWER FACTOR

CAPACITORS

PT375: STANDARD, C1=C2=C3=60/460V

PT275: OPTIONAL, C1=C2=50/460V

C3 NOT PRESENT

313

BYPASS PCB

L1A

L2A

50/60HZ MACHINE

ONLY

BYPASS ASSEMBLY

50HZ MACHINE ONLY

SCHE. S24206-X

7J13

8J13

347

J7

BOARD

347

MENU

SWITCH

S3

346

316D

316D

SPOT

413

B

W

SPOT

(RED)

W

413

1J20

2J20

R8A

216A

217A

R7C

2

1

8

B

375 ONLY

2

1

8

A

2

2

0

A

218A

220B

220B

220A

5/50W

5/50W

275 = 5/50W 4 ea

375 = 25/25W 4 ea

base front

75vac

(375 only)

Free Wheeling diode

left front lower

upper section near lift bale

.015"

near power switch

in reconnect area

in reconnect area

bottom right in RF section

PT375 = 86 vac

PT275 =75 vac

to X2

Fans "ON" @

15A in stick mode

2A in tig mode

"ON" 8 minutes after

weld stops

Meter shows

preset & actual

board mounted parts

+5 LED

+15 LED

Dip Switches select:

a.

re-start enable

b.ramp down to zero

c. see IM for details

and more.

d.most old options

on menu feature now.

Caliberation: see new control bd. instructions

exhaust

intake

inside side box right

min

min

min

flashes with

pulse frequency

stick

thermo

gas

remote

auto

right front lower

10 pin molex

10 pin molex

(right side)

(right front)

"ON" with input power sw.

"ON" with output

Sets weld tables

& CR2 ,CR3 control

right heat-sink

left heat-sink

very top of welder

front

middle section

outside of right side box

(bottom behind fan)

(right side in box)

(bottom right side)

upper left

5KV

K870 foot pedal jumper

to enable Pot (R1) max output

limiter fearure.

Jumper not used

in Robotic molex position J5A

center of base mounted on its side

To & From

IC chip

driver

opto

com

+12

com

+8

to thermo

led & CPU

either is ref

to 231A

Make sure that the rear EXTERNAL

baffle is inplace and not damaged.

TOP FAN

N.C.

N.C.

wounded into

primary

lead

mounted

turns off SCR's

OCV clamp

max current range:

375=340A

275=420A

min current range:

375=2 to 65A

275=2 to 55A

115V common

115V common

115V common

+5

GND

Data

Menu Switch

Clock

menu options( jumper IN)

no menu options ( jumper out)

J8 (6pin)

not used

Menu Switch hold to get to TIGoptions

lift TIG, upslope

tig hot start levels, micro start

pre flow/after flow time extended

see IM for details and more

Menu Switch hold to get to Stickoptions

arc force levels

hot start levels

Push & hold

at power up = defaults

not used:see

menu options

IC chip

controller

large cap and

resistor filter

opto

triac

opto

triac

opto

triac

opto

triac

opto

triac

IC chip

controller

1

1

5

v

a

c

opto

triac

R

7

B

R

7

A

2

3

0

275 ONLY

375 ONLY

current limiting resistors

to main rectifier

BACKGND

RESISTORS

115V common

115VAC

115VAC

SCR drive

ckts

&

snubbers

amp

scaling

R

(top rear)

G-8

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC