E-2E-2

PRECISION TIG 275

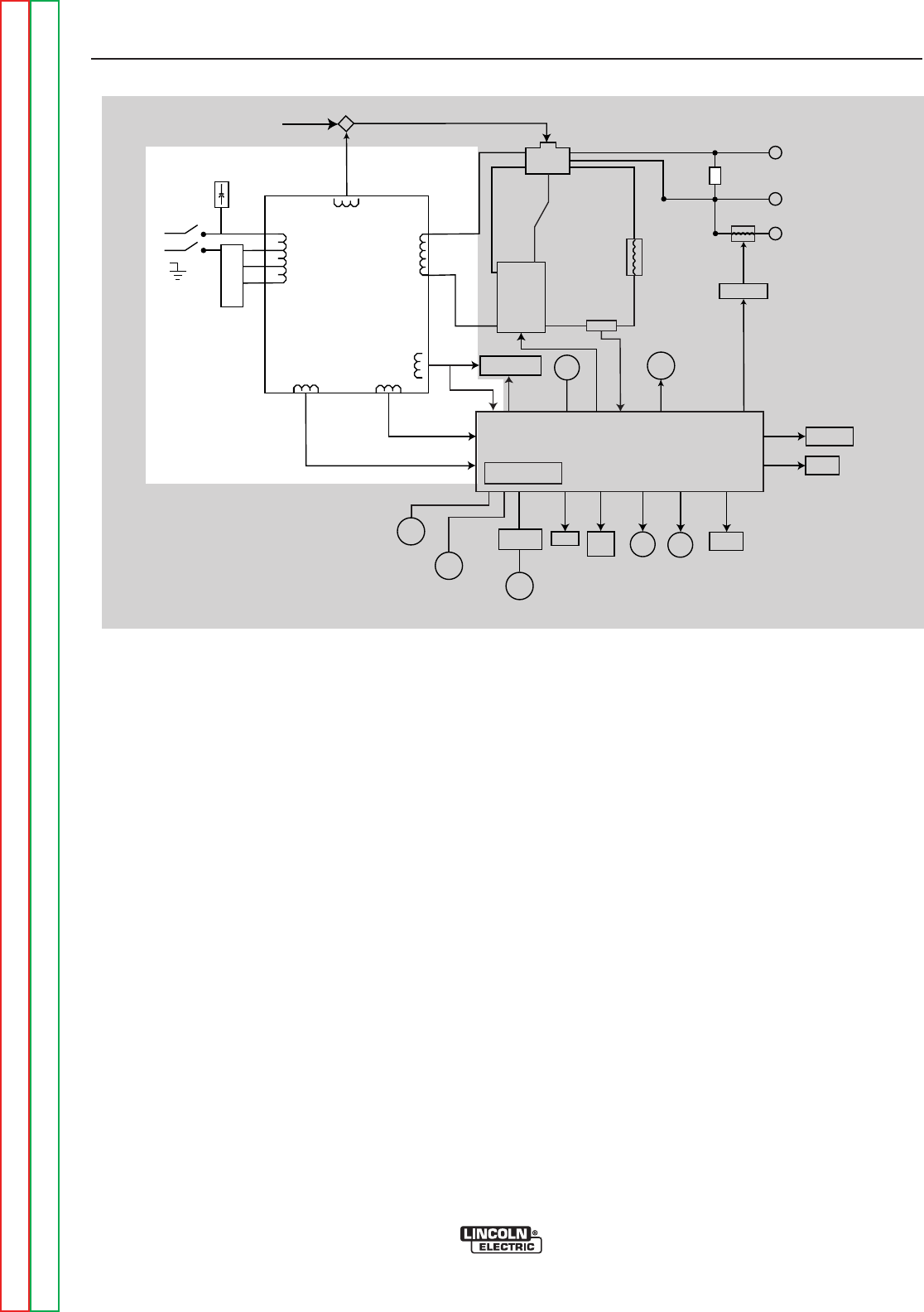

FIGURE E.2 – GENERAL DESCRIPTION AND INPUT POWER CIRCUIT

POWER

SWITCH

RECONNECT

PANEL

O

PTIONAL POWER

FACTOR

POLARITY

SWITCH

B

YPASS BOARD

WORK

FRONT

E

LECTRODE

R

EAR

ELECTRODE

78 VAC

X1

X2

A

C

AC

D

C

DC

S

HUNT

CHOKE

HIGH FREQUENCY

TRANSFORMER

HIGH VOLTAGE

TRANSFORMER

T

HERMOSTAT

1

15 VAC

115 VAC

115 VAC

FAN

GATE LEADS

FEEDBACK

GAS

SOLENOID

115 VAC

115 VAC

LED's

THERMOSTAT

20 VAC

2

0 VAC

CONTROL BOARD

B

ACKGROUND

CIRCUIT

FROM

C

ONTROL

BOARD

63.5 VAC

CORRECTION

CAPACITORS

REAR GANG

SCR

BRIDGE

ADVANCED CONTROL

PANEL RECEPTACLE

MINIMUM

OUTPUT

CONTROL

MAXIMUM

OUTPUT

CONTROL

PROTECTION

BOARD

REMOTE

RECEPTACLE

METER

STICK

TIG

S

WITCH

BALANCE

CONTROL

POST

FLOW

LOCAL/REMOTE

SWITCH

GENERAL DESCRIPTION

The PRECISION TIG 275 is part of a new family of

industrial arc welding power sources able to provide

constant current and single range square wave AC/DC

Tig (GTAW) with new MicroStart

TM

Technology. It incor-

porates independent presettable minimum and maxi-

mum output control with built-in high frequency stabi-

lization for continuous AC Tig welding and reliable DC

Tig starting. The Precision TIG 275 also has AC/DC

stick (SMAW) capabilities. This new design includes

advanced features such as a digital meter, presettable

controls, auto balance

TM

, fan as needed and timers for

fixed preflow and variable post flow of shielding gas. It

features a stick output terminal (front) and a universal

Tig torch connection box (rear) for simultaneous, but

separate, electrode outputs.

INPUT POWER CIRCUIT

The desired single-phase input power is connected to

the PRECISION TIG 275 through the power switch to

the reconnect panel located in the rear of the machine.

The machine can be configured for any one of three

input voltages (208 VAC, 230 VAC or 460 VAC) by con-

necting the jumper strap to the appropriate terminal on

the reconnect panel. When the input power switch is

turned “on,” the input voltage is applied directly to the

primary winding of the main transformer.

The main transformer changes the high voltage, low

current input power to a low voltage, high current out-

put available at the main secondary winding (X1 and

X2). This 78 VAC winding supplies power to the weld-

ing arc. In addition, four auxiliary windings are incor-

porated in the main transformer. The 115 VAC winding

supplies power to the 115 VAC receptacle. Through

the control board, it also powers the gas solenoid, the

high voltage transformer, and the cooling fan. The

cooling fan is activated only when welding current is

sensed. The 63.5 VAC winding provides power for the

DC background current. This circuit is active in the DC

TIG welding mode. The 20 VAC windings are included

in the main transformer assembly. The 20 VAC winding

is rectified on the control board and is used in the trig-

ger circuitry. The other 20 VAC winding is used by the

control board for phase detection. This AC voltage is

also rectified to several DC voltages and regulated to

+15 VDC and +5 VDC power supplies that operate the

circuitry on the control board.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

THEORY OF OPERATION