F-6F-6

PRECISION TIG 275

TROUBLESHOOTING & REPAIR

Observe Safety Guidelines TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

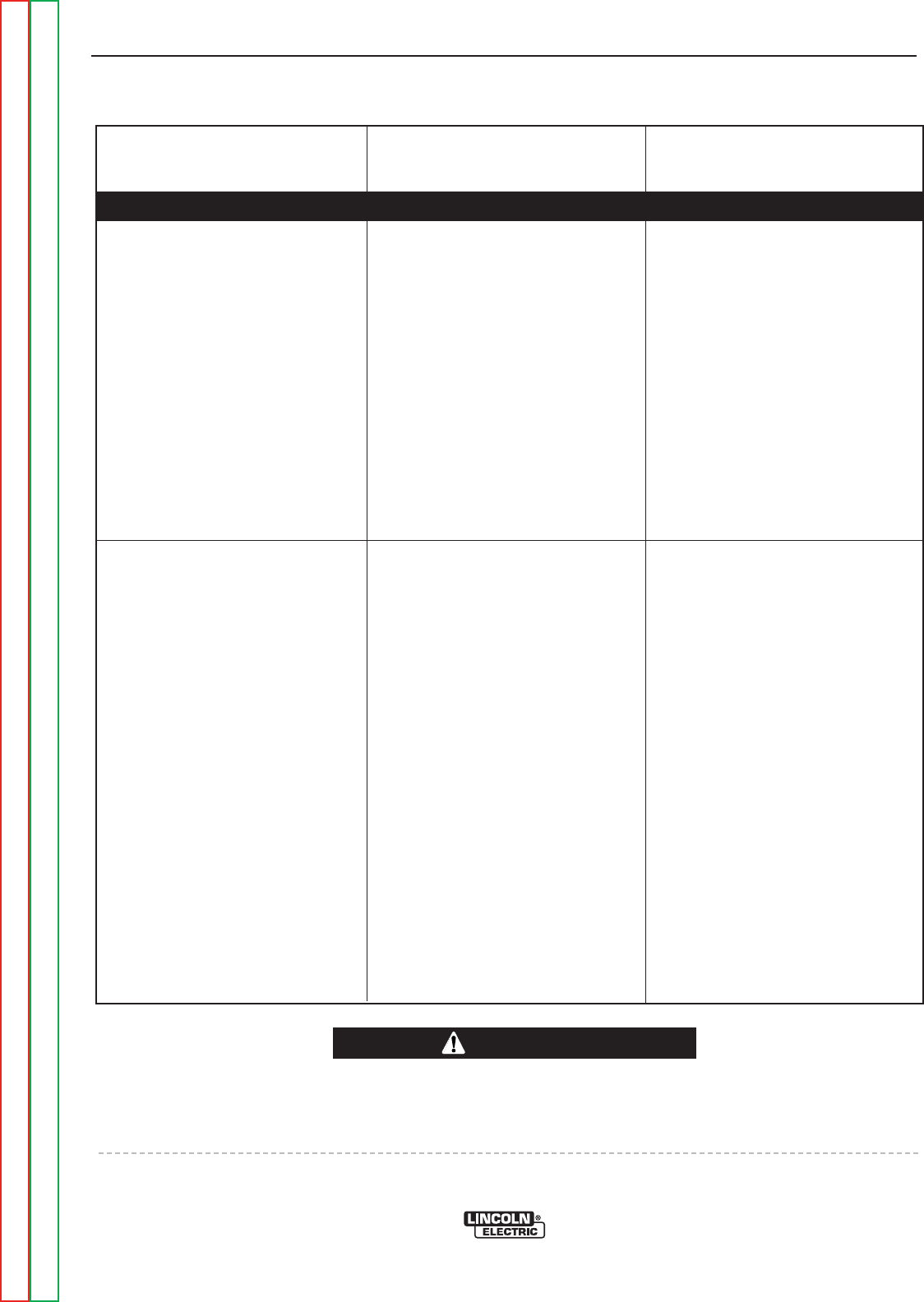

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

No output from the machine in

either Stick or TIG modes. The

thermal light is on.

NOTE: BEFORE REPLACING A

CONTROL BOARD

If an Advanced Control Panel is

installed, remove it and replace

the Jumper in connector J-3. If

the machine functions normally,

the Advanced Process panel or

harness is defective.

1. The welding application may

have exceeded the recommend-

ed duty cycle. Allow the fan to

cool the until the thermal light is

off.

2. The air louvers may be blocked.

Remove the air obstruction and

allow the unit to cool.

1. One of the thermostats may be

faulty. Check or replace. See

the Wiring Diagram.

2. Check for loose or faulty wires

on the thermostats and associat-

ed circuitry. See the Wiring

Diagram.

3. The fan motor may be faulty or

mechanically obstructed. The

fan should run when welding or

when a thermostat is open.

4. The control board may be faulty.

The machine does not respond (no

gas flow, no high frequency and no

open circuit voltage) when the arc

start switch or Amptrol is activated.

The thermal light is not lit.

NOTE: BEFORE REPLACING A

CONTROL BOARD

If an Advanced Control Panel is

installed, remove it and replace

the Jumper in connector J-3. If

the machine functions normally,

the Advanced Process panel or

harness is defective.

1. Make sure the machine is in the

TIG mode.

2. The Amptrol or arc start switch

may be defective. Check for

continuity ( zero ohms) between

pins “D” and “E” on the cable

connector when the Amptrol or

arc start is pressed.

3. Check the Local/Remote switch

for proper operation.

1. Perform the Protection Board

Test.

2. Perform the T1 Transformer

Test.

3. The control board may be faulty.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CAUTION