B-13

OPERATION

B-13

PRECISION TIG 275

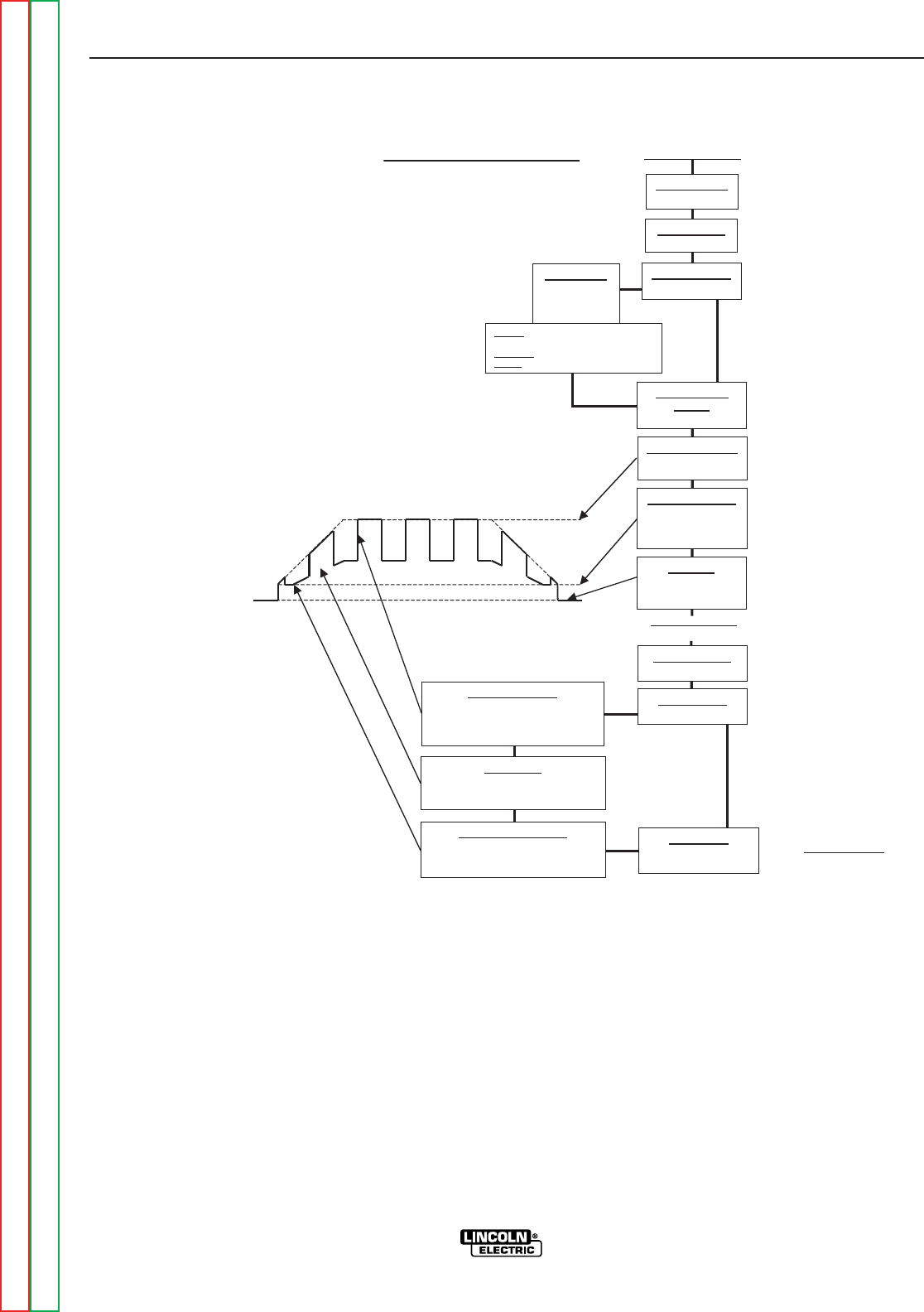

FIGURE B.6

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Max. to Min.

Amptrol

Min. to Max.

Amptrol

Setup for TIG Amptrol Welding

Advanced Panel

(If used)

Standard Controls

Power Switch

ON

P

olarity Switch

AC or DC-

Mode Switch

TIG

AC Balance

AUTO

or

Set:

More + for alum. oxide “Cleaning“

w/o “spitting”or“wetting“ loss.

B

alanced for equal

+

and

-

current.

More

-

for higher “Penetration“.

Local/Remote

Switch

REMOTE

Trigger Switch

2-STEP

Pulse Switch

ON or OFF

Pulse Frequency

4-6 pps is a typical initial setting.

Set for bead shape and travel speed:

Higher for thinner plate and faster travel.

Lower for thicker plate and slower travel.

% On Time

40-60% is a typical initial setting.

Set for total heat of Peak current:

Lower reduces distortion and burn-thru.

Background Current

40-60% is a typical initial setting.

Set as low as will maintain a pulse arc

(Will not drop below

Min.Output

setting.)

Downslope

ZERO

For no arc-out delay.

Minimum Output

Press Display switch

and Set to desired min.

A

mptrol (Start/Crater)

o

utput level.

Postflow

Set as low as required.

Higher for larger

t

ungsten and current.

Maximum Output

S

et to desired max.

A

mptrol output level.

AAddvvaanncceedd PPaanneell

Controls

SETUP GUIDELINES FOR TIG WELDING

WITH AN AMPTROL

Both the Hand and Foot Amptrols work in a similar

manner. They are meant to be used for remote current

control for TIG welding using the machineʼs 2-Step trig-

ger mode (See Item 12).

The Amptrol is capable of controlling the output of the

Precision TIG over the range between the level preset

by the Minimum Output control when the Amptrol is at

its inactivated state, and the level preset by the

Maximum Output control when the Amptrol is at fully-

activated state.

It is important to note that even with the Precision TIGʼs

new MicroStart

TM

Technology, some tungsten may be

difficult to start at the low (2 amps) minimum rating of

the machine. Rather than guessing where to depress

the Amptrol to start the arc reliably, the Minimum

Output control allows presetting the exact level, so reli-

able starts, as well as minimum crater-fill levels, can be

consistently obtained at the minimum Amptrol (inacti-

vated ) state. FIGURE B.6 shows Precision TIG setup

for TIG welding with an Amptrol.