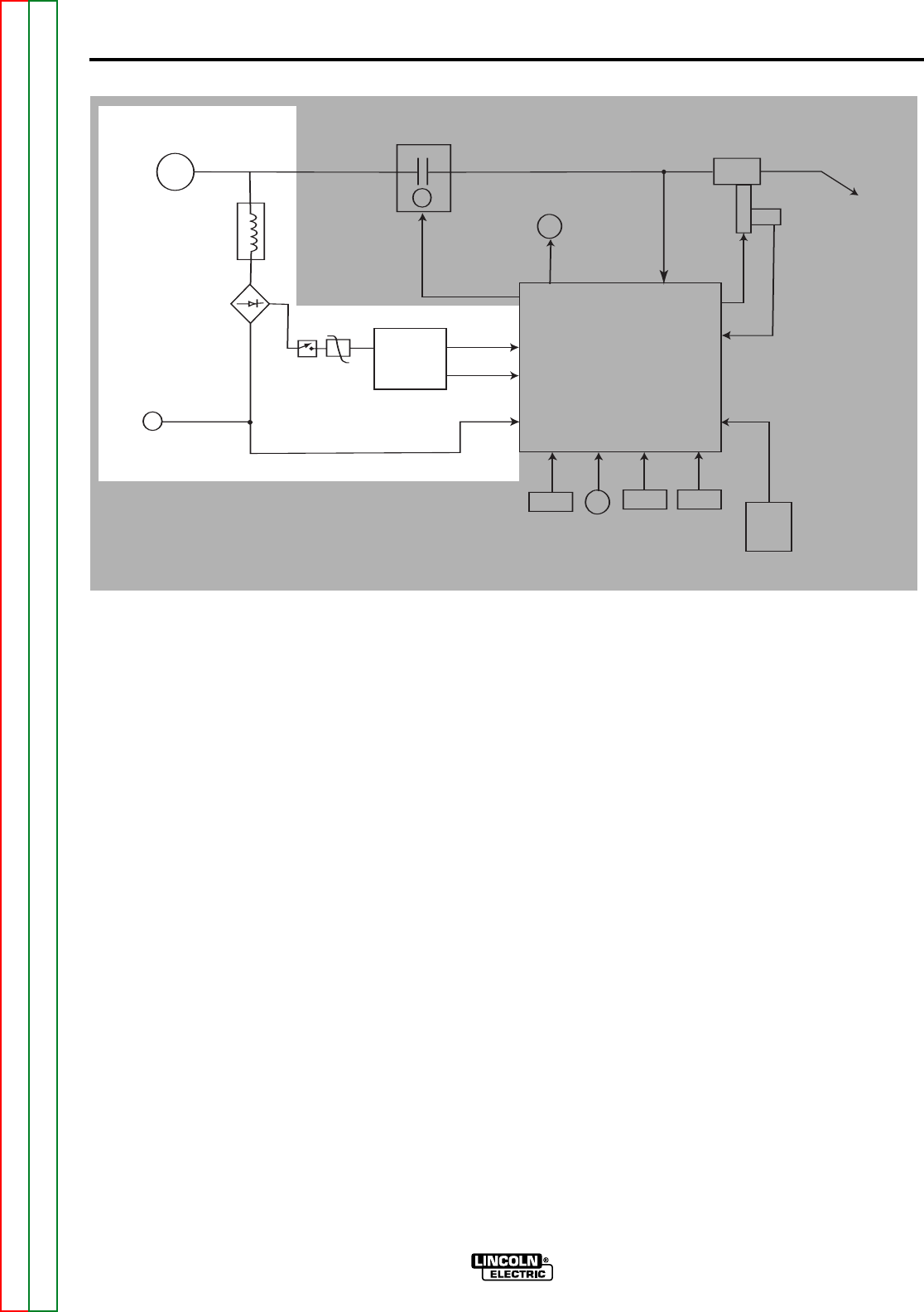

FIGURE E.2 – GENERAL DESCRIPTION & INPUT POWER

CONTACTOR

ELECTRODE

INPUT VOLTAGE

TOROID

ASSEMBLY

FULL

WAVE

BRIDGE

WORK

SENSING

LEAD

ON/OFF

SWITCH

MOV

BOOST

POWER

SUPPLY

BOARD

FEED HEAD

BOARD SUPPLY

DRIVE MOTOR

SUPPLY

"WORK" VOLTAGE FEEDBACK #21

GAS

SOLENOID

"ELECTRODE"

FEEDBACK

VOLTAGE #67

FEED

PLATE

M

O

T

O

R

HALL

EFFECT

MODULE

RPM FEEDBACK

ARMATURE

WELDING

GUN

DISPLAY

BOARD

COLD

INCH

SWITCH

WIRE

FEED

SPEED

CONTROL

TRIGGER

INPUT &

PROCEDURE

TRIGGER

INTERLOCK

SWITCH

SPI COMMUNICATIONS

SHIELDED CABLE

FEED HEAD

CONTROL BOARD

THEORY OF OPERATION

GENERAL DESCRIPTION

The LN-15 is a lightweight portable semi-automatic

wire feeder. The “Across the Arc” model is capable of

operating with Lincoln DC power sources supplying

between 15VDC to 110VDC. The LN-15 is designed

for semi-automatic use and has a 60% duty cycle rat-

ing.

By attaching the work clip to the work piece and the

LN-15 electrode cable to the Lincoln power source the

LN-15 is ready to feed wire and weld. The LN-15 can

be connected for either welding polarity without any

changes to the LN-15. When the gun trigger is acti-

vated and wire feeds and an internal contactor ener-

gizes the electrode output.

The wire drive is capable of operating in either the con-

stant voltage or the constant current mode. A con-

stant current voltage power source is recommended

for flux-cored arc welding (FCAW) and gas metal arc

welding (GMAW) to obtain code quality results.

For non-critical quality applications a constant current

power source may be used.

The LN-15 comes factory equipped with a K1500-2

Tweco style #2-#4 gun bushing.

The “dual procedure” mode drops the wire feed speed

83% from the original set point. The voltage setting

remains the same.

INPUT POWER

The DC voltage supplied from the power source is

applied to the LN-15 through the electrode cable and

the work sensing lead. The voltage is applied to the

full wave bridge through a toroid assembly. When the

ON/OFF switch is put in the ON position the positive

DC voltage from the bridge is applied to the

Boost/Power Supply board through an M.O.V. assem-

bly. This M.O.V. is needed to protect the Boost/Power

board from inductive energy stored in the welding

cables.

The Boost/Power Board takes the weld voltage and

boosts it to 80VDC or the actual arc voltage being

applied. (Whichever is greater). The outputs of the

Boost/Power board are two separate 80VDC+ supply

voltages. One of these is utilized and regulated by the

Feed Head Control board to power the wire drive

motor. The other 80VDC supply is regulated to create

several plus and minus regulated DC supplies. These

+/-15VDC and +/-5VDC supplies are used to power

the electronics within the Feed Head board and other

components in the LN-15 such as the gas solenoid.

E-2 E-2

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

LN-15