YPE

OF

PROBLEM

Condition

B

(continued)

Condition

C

Red

lamp on, clear lamp

off

Unplug

sprayer1

WHAT TO CHECK

f

check is

OK,

go

to

next

check

i.

Check microswitch

1306).

With no fluid

pressure in the pressure control discon

-

nect wires TP18 and TP19. Check con

-

tinuity across switch terminals with an

ohmmeter. Switch contact should be

closed. Depress actuator

bunon. An

audible

"click" indicates the contacts

have opened. Ohmmeter should read in

-

finity.

i.

Check circuit board

(3401

by substituting

with a good board. See page

22.

.

Check circuit board

(3401

by removing

from box

wirhout

disconnecting wires;

sea

page

22

for removal procedure.

WARNING:

Removing the circuit board

while still wired over

-

rides the optical

.

to over

-

pressurize, if the microswitch

detector which could cause the sprayer

does not function properly. Tum the

sprayer on

ONLY

long enough to check

lamp condition, then shut

off

immediate

-

ly.

WARNING:

To reduce the risk of elec

-

tric shock, handle board by edges only1

Do

not allow any metal objects to come

in

contacl with the boardl

should be

on

now

-

removing the circuit

Plug in and turn on sprayer. Clear lamp

board over

-

rides the optical detector.

Turn

off

and unplug sprayer.

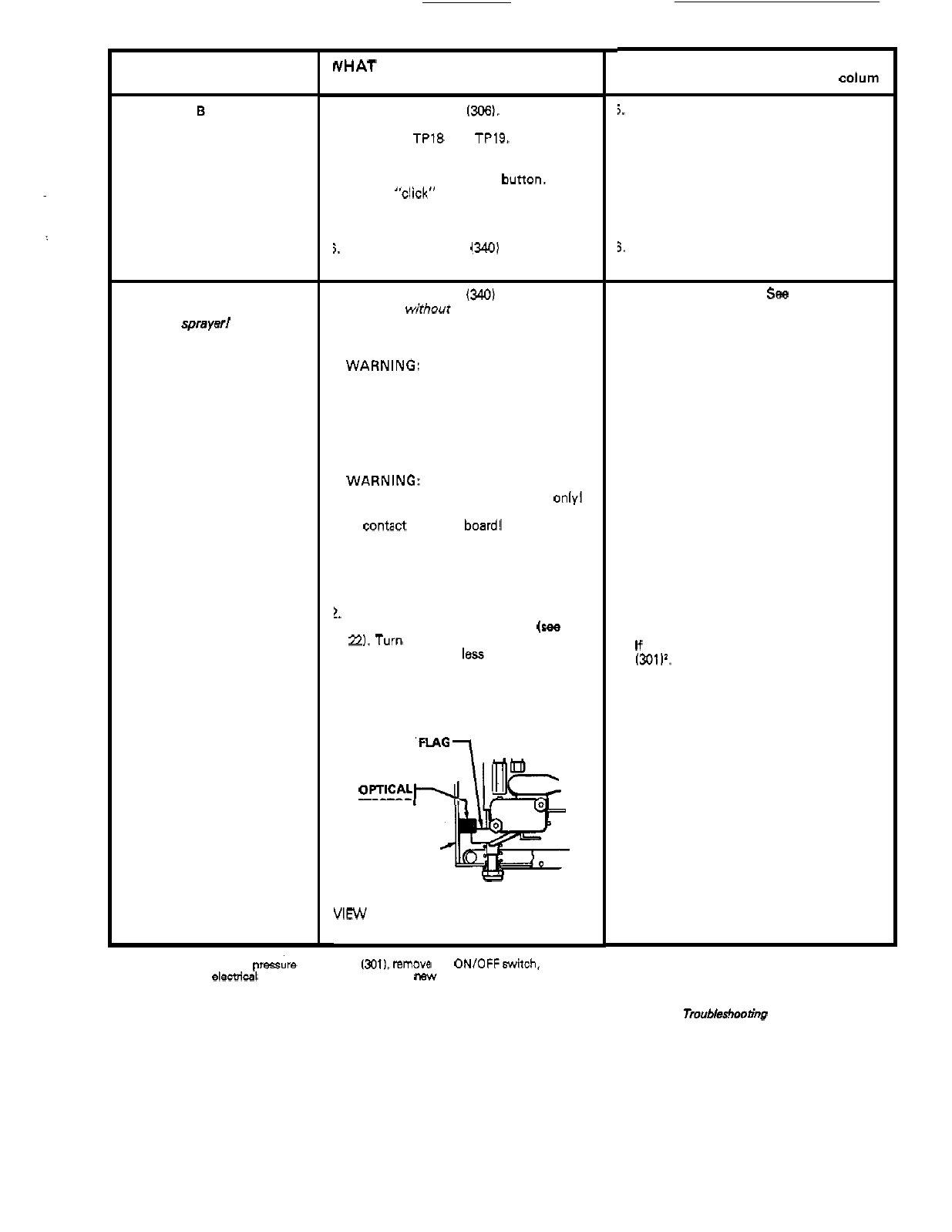

!.

Check bourdon tube flag and detector

position. Reinstall circuit board

(see

page

22.

Turn pressure setting to maximum;

flag should extend

less

than half way into

optical detector slot from the bonom.

DETECTOR

C

I

R

C

U

I

T

-

BOARD

VIEW

OF

OPTICAL DETECTOR AND

FLAG

'When replacing

the

bare pressire control box 13011.

remow

the

ON/OFFswitch,

bridge,

circuit

board

and

elecbical

hardware and

reinstall

in

the

new bare box.

WHAT TO

DO

If

check

is

NOT

OK

refer

to

this colurn

5.

Replace microswitch. See page 19.

3,

Replace circuit board. See page

22.

I.

Replace circuit board.

Sea

page

22.

2.

Calibrate pressure control to

sea

if

that

corrects problem.

See

page

24.

If

not, replace bare pressure control box

13011'.

See

page

23.

Tmubleshooting continued on next

page.

307

-

671

11