SETUP

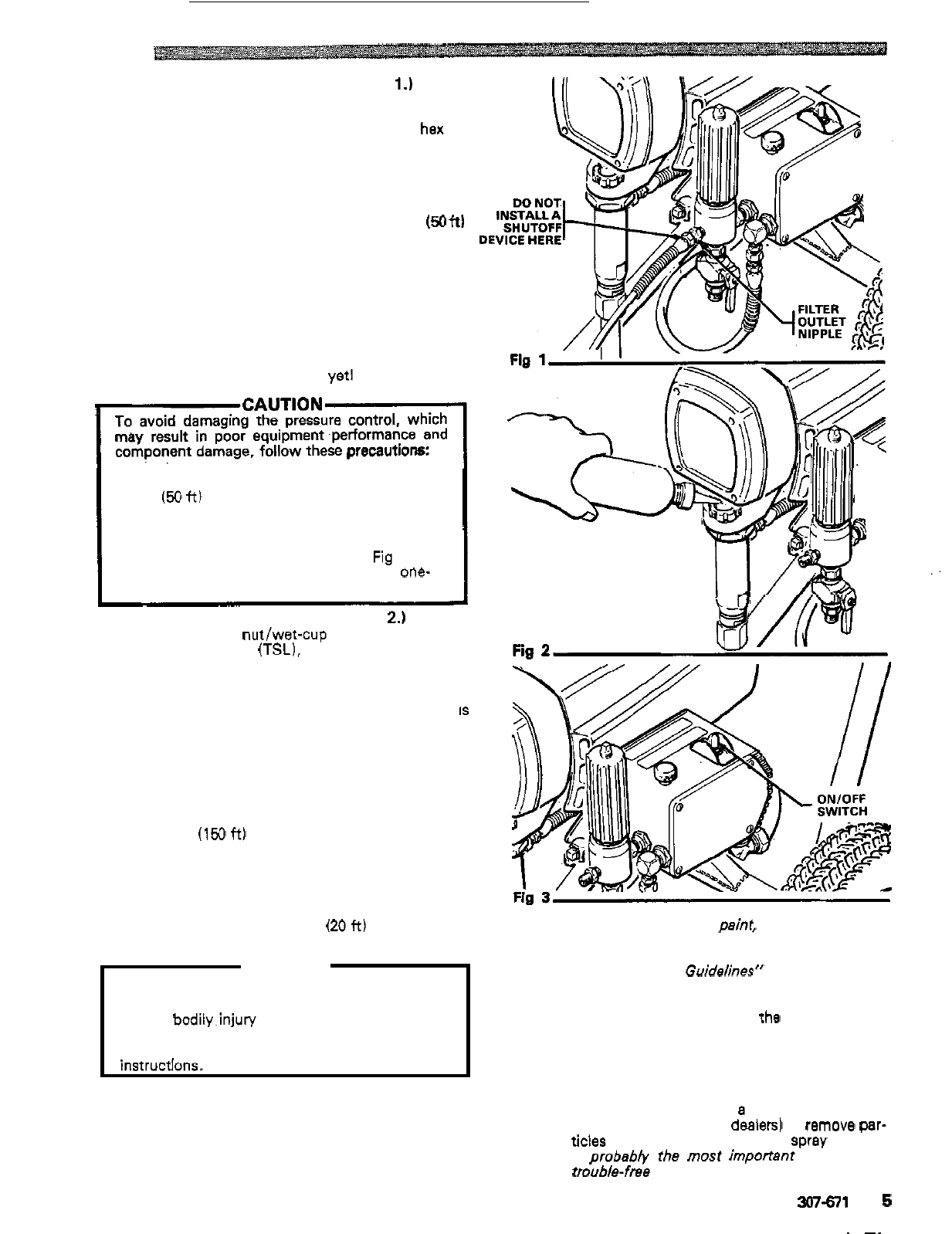

1.

Connect

Hose

and Gun (Refer

to

Fig

1.)

NOTE:

When tightening fittings at the pressure con-

trol, hold one wrench firmly on the hex of

the pressure control fitting

to

keep

it

from

rotating. Use another wrench

to

tighten the

mating fitting.

a. Remove the plastic cap plug from the filter

outlet nipple and tightly screw the

15.2

m

(50

ft)

fluid hose onto the nipple.

b. Tightly connect the whip hose between the

c. Don't use thread sealant on swivel couplings.

The sealant can prevent the swivel from

rotating freely.

fluid hose and the gun inlet connection.

d. Don't install the spray tip

yet1

IcAUTioNl

To avoid damaging the pressure control, which

may result in poor equipment performance and

component damage, follow these precautlons:

1.

2.

3.

4.

Always use nylon spray hose

at

least

15.2

m

(50

ft)

long.

to act

as

a

pulsation dampener.

Never use

a

wire braid hose as it

is

too rigid

Never install any shutoff device between

the filter and the main hose. See

Flg

1.

Always use the main filter outlet for one-

gun operation. Never plug this outlet.

~~

2.

Fill Packing Nutiwet-Cup

(See

Fig

2.)

Throat Seal Liquid (TSL), supplied.

Fill

the packing nut/wet-cup

1/3

full with Graco

3.

Check Electrical Service

a.

Be

sure the electrical service is properly rated

for your sprayer and that the outlet you use

Is

properly grounded.

b. Attach an appropriate plug to the power supply

cord, according

to

your local electrical codes.

c. Use an extension cord which has

3

wires of

a

minimum

12

gauge size, and a maximum of

45

m

(150

ft)

long. Longer lengths may affect

sprayer performance.

4.

Plug

in

the Sprayer

a.

Be sure the ONlOFF switch

is

OFF. 'Refer

to

Fig

3.

Then plug the cord into

a

grounded elec

-

trical outlet

at

least

6

m

(20

ft)

away from the

spray area.

WARNING

Proper electrical grounding is essential

to

reduce

the risk of fire or explosion which can result in

serious

bodily.injury and property damage. Refer

to the warning section

FIRE

OR

EXPLOSION

HAZARD

on page

3

for more detailed grounding

instructlons.

5.

Flush the pump to remove the lightweight oil

which was left in to protect pump parts after fac-

tory

testing.

a. Before using water-base paint, flush with

mineral spirits followed by soapy water, and

then

a

clean water flush.

b. Before using oil

-

base painr, flush with mineral

c.

See

"

Flushing Guidalines" on page

8

for

6.

Prepare the paint according

to

the manufacturer's

recommendations.

a.

Remove any skin that may have formed.

b.

Stir the paint

to

dissolve hard pigments.

c. Strain the paint through

5

fine nylon mesh

bag

ticks that could clog the filter or spray tip. This

(available

at

most paint dealers)

to

remove par-

is probably the

mosr

importanr step toward

trouble-free spray painting,

307-671

6

spirits only.

flushing procedure.

~ ~~