FLUSHING

GUIDELINES

When to Flush

1.

New Sprayer. Your new UltraQ

400

Sprayer was

factory tested in lightweight motor'oil which was

5.

Storage.

left

in to protect pump parts. spirits and leave the pump, hose and gun filled with

Water

-

base paint: flush with water, then mineral

Before using water

-

base paint, flush with mineral

spirits, followed by soapy water, and then

a

clean

mineral spirits. Shutoff and unplug the sprayer,

open the drain valve to relieve pressure and leave

water flush.

Before using oil

-

base pain!, flush with mineral

open.

spirits only. and unplug the sprayer, open the drain valve to

Oil

-

base paint: flush with mineral spirits. Shutoff

2.

Changing Colors. Flush with*a compatible solvent

relieve pressure and leave open.

such as mineral spirits or water.

6.

Startup after storage.

3.

Changing from water-base

to

oil-base paint.

Before using water

-

base paint, flush out mineral

Flush with soapy water, then

minera1,spirits.

spirits with soapy water and then

a

clean water

flush.

4.

Changing from oil-base to water-base paint.

Flush with mineral spirits, followed by soapy water, spirits with the fluid to be sprayed and the sprayer is

When using oil

-

base paint, flush out the mineral

then

a

clean water flush. ready to use.

How to Flush

1.

Follow the Pressure Relief Procedure Warning

on page

6.

'

2.

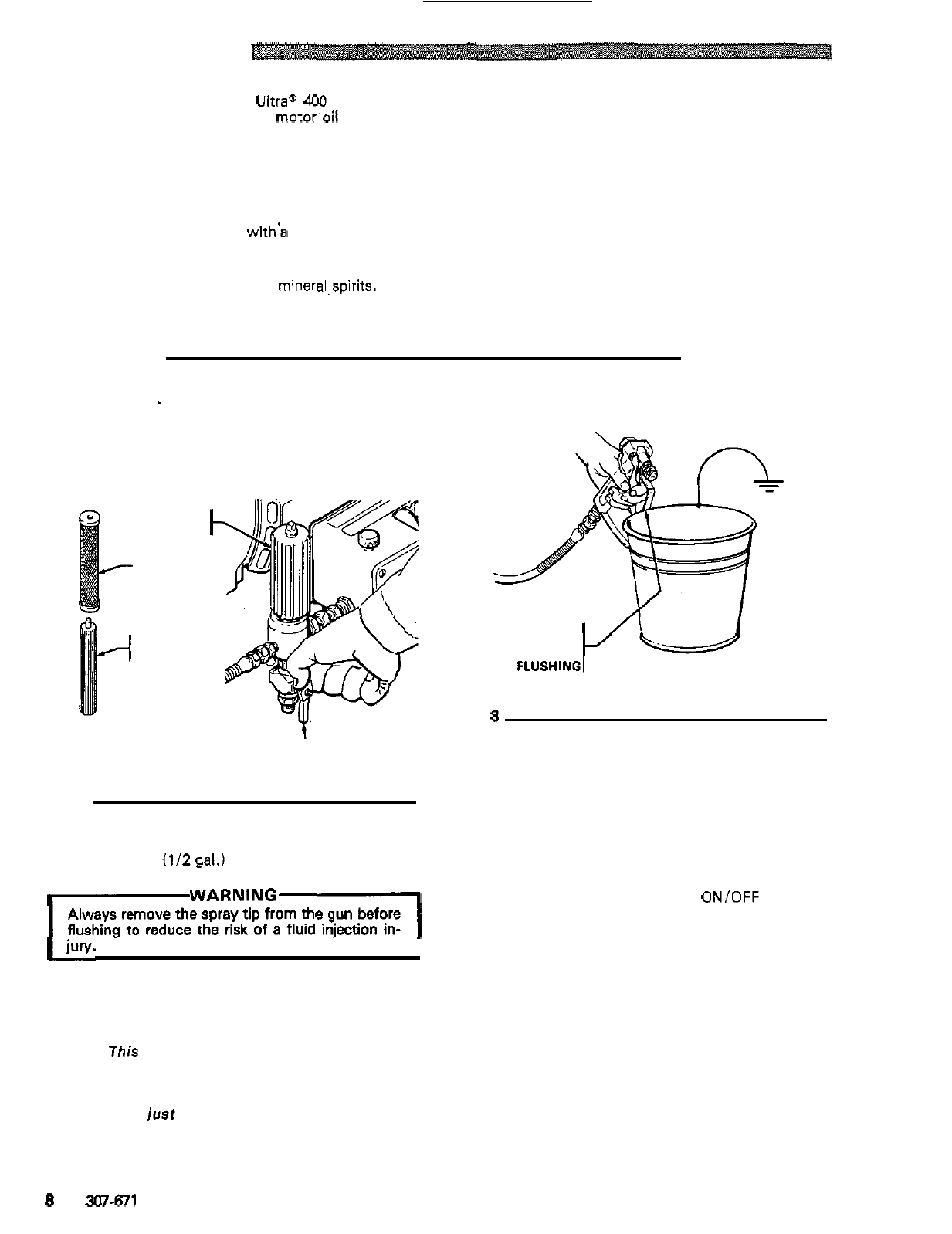

Remove the filter bowl and screen; see manual

307

-

273

supplied. Clean the screen separately and

install the bowl without the screen.

FILTER

BOWL

SCREEN

MAINTAIN FIRM

METAL TO METAL

CONTACT WHEN

FILTER

SUPPORT

Fig

8

4

DRAIN VALVE

SHOWN OPEN

Fig

7

3.

Close the filter drain valve.

4.

Pour

2

liters

(112

gal.) of compatible solvent into a

bare metal pail. Put the suction tube in the pail.

Always remove the spray tip from the gun before

flushing to reduce the risk of

a

fluid injection in-

IWARNING1

5.

Disengage the gun safety latch.

6.

Point the spray gun into

a

grounded metal waste

container and with a metal part of the gun firmly

touching the metal container, squeeze the gun trig-

ger.

This procedure helps avoid static sparking

which can cause fire or explosion and splashing.

With the gun triggered, turn the ONIOFF switch to

clockwise

just

until

the sprayer starts. Keep the

ON

and slowly

turn

the pressure adjusting knob

gun triggered until clean solvent comes from the

nozzle. Release the trigger and engage the gun

safety latch.

7.

Check

all

fluid connections for leaks. If any leak,

follow the Pressure Relief Procedure Warning

on page

6.

Now tighten the connections, start the

sprayer, and recheck the connections for leaks.

8.

Remove the suction tube from the pail. Disengage

the gun safety and trigger the gun to force solvent

from the hose.

Do

not let the pump

run

dry for

more than

30

seconds to avoid damaging the

pressure control. Then turn ON/OFF switch

to

OFF and engage the gun safety latch.

9.

Unplug the power supply cord. Open the drain

valve and leave open until you

are

ready to use the

the clean screen. Reinstall the bowl, hand tight

sprayer again. Unscrew the filter bowl and reinstall

only.

10.

If

you have flushed with mineral spirits and are go-

ing to use

a

water-base paint, flush with soapy

water followed by

a

clean water flush. Then repeat

Step

1.

8

307-671