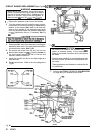

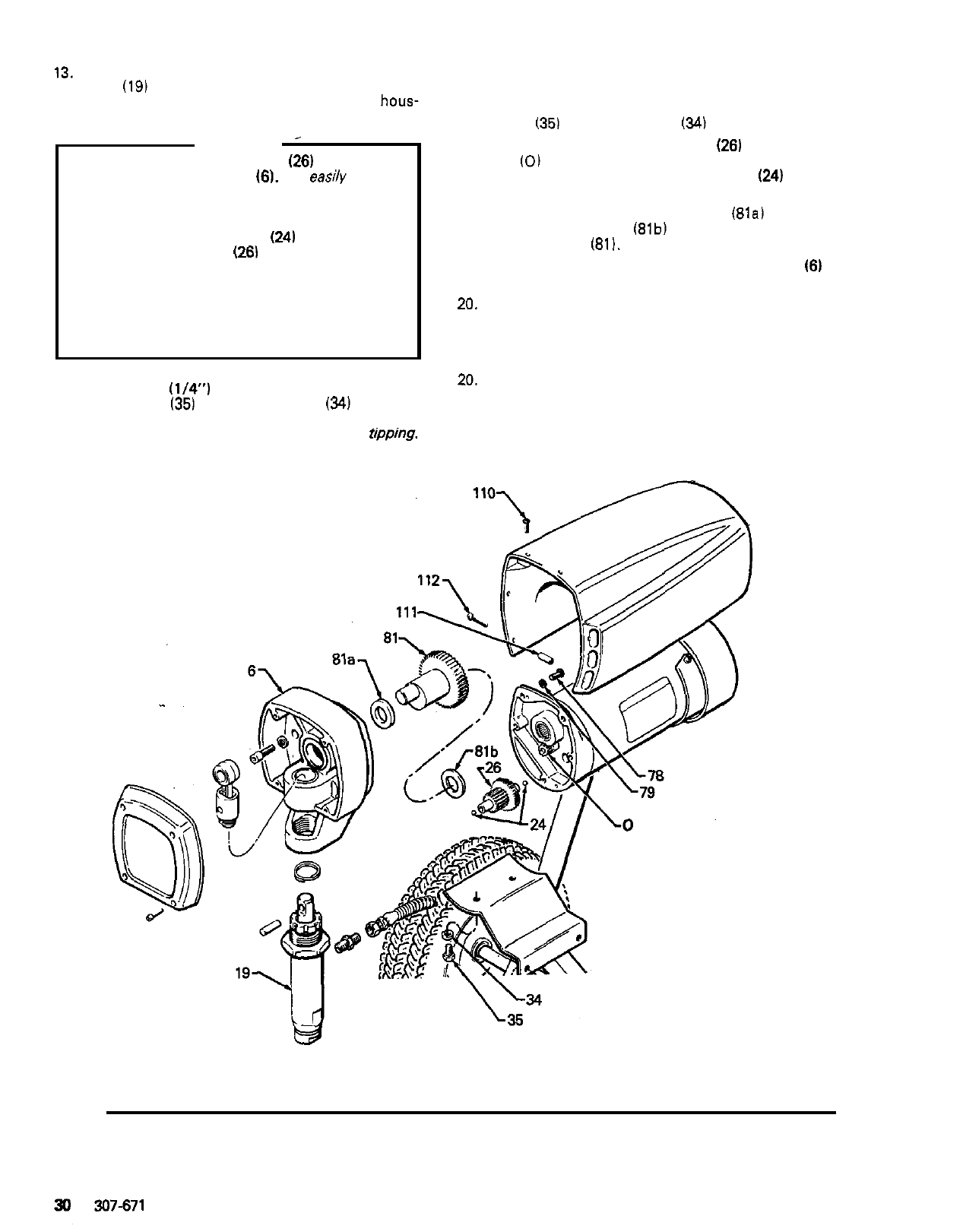

13.

Use

a

plastic mallet to gently tap the displacement

pump

(19)

from

the

rear to loosen the drive housing

ing away from the front end bell.

(6)

from the front end bell. Then pull the drive hous-

CAUTION

~

DO

NOT allow the gear cluster

(26)

to fall when

removing the drive housing

(6).

It

is easily damag-

ed if dropped. The cluster may stay engaged in

either the front end bell or the drive housing.

DO

NOT lose the thrust balls

(24)

located

at

each

end of the gear cluster

(261

or allow them to fall

with grease, usually stays in the gear recesses, but

between gears. The ball, which is heavily covered

could be dislodged.

If

caught between gears and

not removed, the balls will seriously damage the

drive housing. If the balls are not in place, the

bearings will wear prematurely.

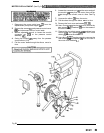

14.

Use

a

6

mm

(114")

hex key wrench to remove the

two screws

(35)

and lockwashers

(34)

from the

underside

of

the motor mounting frame. Be

sure

to

support

the motor to keep the sprayer from

tlppmg.

15.

Lift the motor assembly

off

the frame.

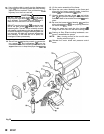

16.

Place the new motor assembly on the frame and

align

-

with the frame mounting holes. Install the

screws

(351

and lockwashers

(34)

tightly.

17.

Liberally grease the gear cluster

(26)

and pinion

gear

(0)

and pack

all

bearings in the motor front

end bell. Check to be sure the thrust balls

(24)

are in

place.

18.

Be sure the bronze

-

colored bearing (81a1 and the

silver

-

colored bearing (81b) are properly placed on

the crank shaft

(81).

19.

Align the gears and push the drive housing

(6)

straight onto the front end bell and locating pins.

20.

Starting at Step

13

and working backwards, con-

tinue to reassemble the sprayer.

NOTE:

Use

a

turning motion on the conduit when

feeding wires through

it.

20.

Reinstall the motor shield and pressure control

cover.

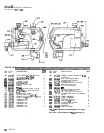

Fig

32