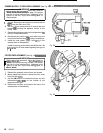

PRESSURE CONTROL REPLACEMENT

the risk of a fluid injection injury, splashing in the

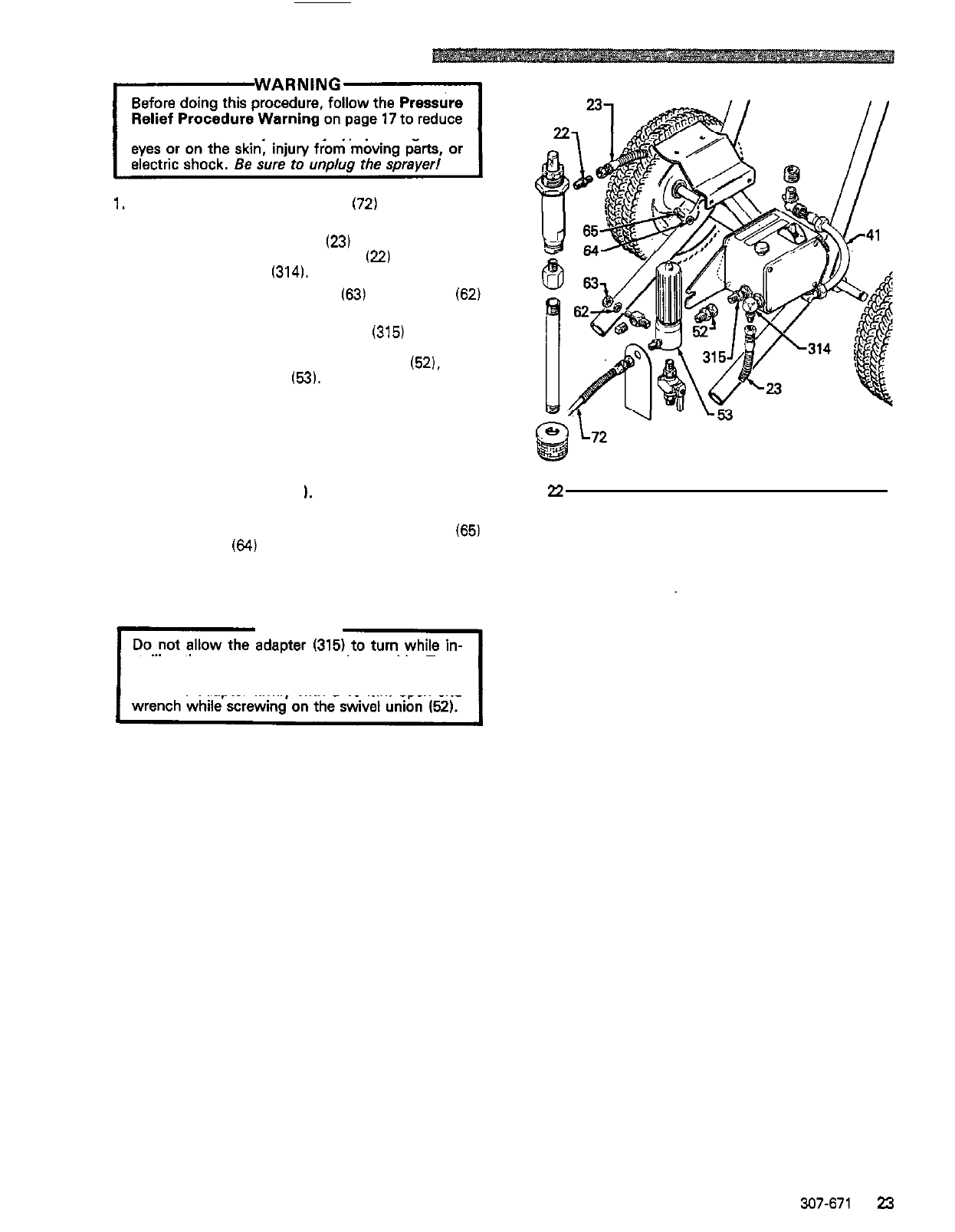

1. Disconnect the main fluid hose (72) and the secon

-

dary fluid hose, if used, from the sprayer.

2. Disconnect the fluid hose

(23)

from between the

displacement pump outlet nipple

(22)

and pressure

control inlet elbow

(314).

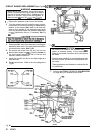

3.

Loosen the filter bracket nut

(63)

and washer

(62)

using a 19

mm

open end wrench.

4.

Hold the pressure control adapter (315) firmly with

wrench to loosen the swivel union

(52).

then

a

19

mm

open end wrench.

Use

an adjustable

remove the fluid filter

(53).

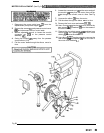

5. Remove the pressure control cover and screws, and

terminals.

disconnect the four motor leads at the appropriate

6. Refer

to

CIRCUIT BOARD REPLACEMENT

on

page

22,

remove the circuit board and retain.

7.

Remove the conduit (41

1.

Fig

22

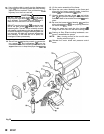

8.

Use

a

13 mm open end wrench to loosen and

remove the pressure control mounting screws 165)

and washers

(64)

located below the pressure con

-

trol box. Remove the box.

9. Install the new pressure control assembly

in

the

reverse order of disassembly.

CAUTION

stalling the new pressure control assembly. Turn

-

ing

it

can damage the sensitive bourdon tube.

Hold the adapter firmly

with

a 19 mm open end

10.

Perform the

STALL PRESSURE CALIBRATION

starting on page 24, before regular operation of the

sprayer.

307-671

23