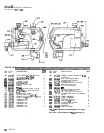

MOTOR

BRUSH

REPLACEMENT

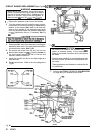

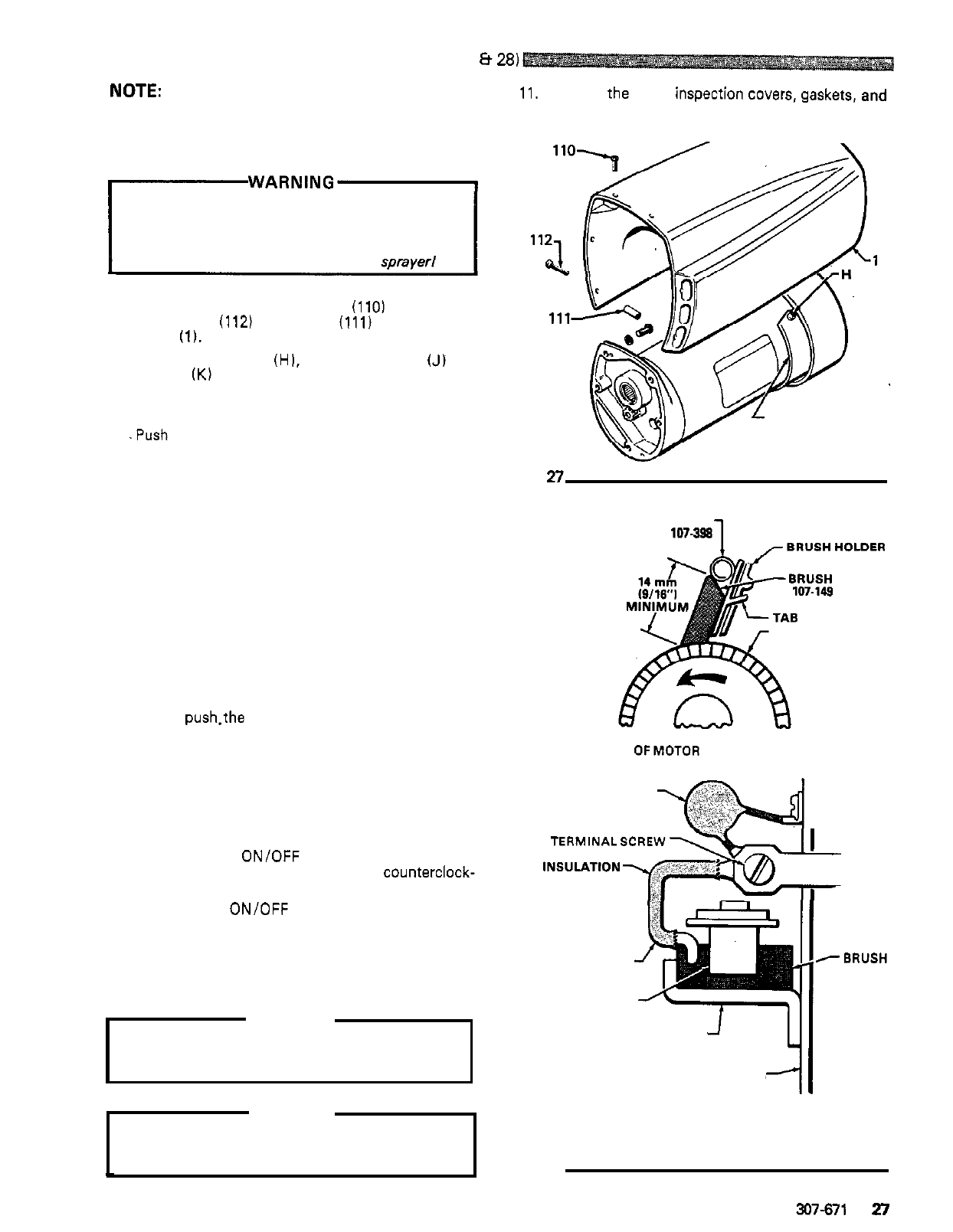

(See Figs

27

8

28)

NOTE:

New motor brushes are included with each

11.

Reinstall the brush inspection covers, gaskets,

and

Packing Repair Kit. Replace them when screws. Reinstall the motor shield and screws.

replacing the packings, and/or when they

the longest side.

have been worn to a minimum of

9/16

on

Before doing this procedure, follow the Pressure

the risk of fluid injection injury, splashing

in

the

Relief Procedure Warning on page

17

to

reduce

eyes or on the skin, injury from moving parts or

electric shock.

Be sure

to

unplug the sprayer1

1.

Remove the four short screws

(110)

and the

two

long screws (112) and spacers

(111)

from the motor

shield

(1).

Remove the shield. See Fig 27.

2. Remove the screws

(HI,

inspection covers

(JI

and

gaskets

(K) on each side of the motor. See Fig 27.

3.

Loosen

the brush lead terminal screw and remove

the lead.

4.

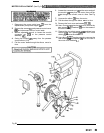

.Push down on the spring clip slightly then pull the

clip away from and out

of

the brush holder. Refer to

Fig 28. Keep the spring clip.

5.

Remove and discard the brush.

J.K

Fig

n

6.

Inspect the commutator for excessive pitting, burn

-

NOTE:

A black color on the commutator is normal.

ing or gouging.

SPRING CLIP

107-398

7.

8.

9.

Have the commutator resurfaced by a

qualified motor repair shop if the brushes

seem to be wearing too fast.

edges are as shown in the first part of Fig

28,

and

Place a new brush

in

the holder

so

the beveled

the brush lead is routed as shown

in

the second part

of Fig 28.

the brush holder until the clip tab engages in the

Slowly

push.the tabbed end of the spring clip into

holder

and

the rolled portion of the tension spring

rests squarely on the brush.

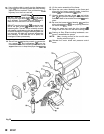

Route the brush lead to the terminal and tighten the

terminal screws. Be sure the brush lead does not

touch any part of the armature or motor housing.

COMMUTATOR COMMUTATOR

SIDEVIEW

OFMOTOR BRUSH INSTALLATION

CAPACITOR

I

10.

Test the brushes:

TERMINALSCREW

a.

With the ON/OFF switch OFF, turn the

pressure control knob all the way

counterclock-

wise to minimum pressure. Plug

in

the sprayer.

b. Turn the

ON/OFF switch ON and slowly

in

-

crease the pressure until the motor comes up to

full speed.

c.

Inspect the brush and commutator contact area

for excessive arcing. Arcs should not

"

trail

"

or

circle around the commutator surface.

WARNING

Do

not touch the brushes, leads, springs or brush

BRUSH HOLDER

holders while the sprayer is plugged in

to

avoid

electric shock and possible serious bodily injury.

MOTOR END BELL

BRUSH LEAD

SPRING CLIP

-BRUSH

Do

not run the sprayer dry for more than

30

CAUTION

seconds while checking the brushes to avoid

damaging the displacement pump.

Fig

28

SHOWN WITH MOTOR LEAD

DETAIL OF MOTOR BRUSH

FACING BACK OF MOTOR

~

307-671

27