TYPE OF PROBLEM

NO OUTPUT

(Continued)

Motor runs but pump does

not stroke

EXCESSIVE PRESSURE

FLUCTUATIONS

Spray panern variations.

MOTOR IS HOT

e

RUNS INTERMllTENTLY

WHAT TO CHECK

If

check is

OK,

go

to next check

,

Check to see

if

intake valve ball and

piston ball are seating properly.

See

manual 307-793.

.

Check for leaking around throat packing

nut which may indicate worn or damag

-

ed packings.See manual 307-793.

.

Check displacement pump connecting

rod

pin.

See

page 26.

,

Check connecting rod assembly for

damage. See page 25.

.

Be sure crank

in

drive housing rotates;

plug

in

sprayer and turn on momentarily

to check. Turn

off

and unplug sprayer.

See

page 25.

.

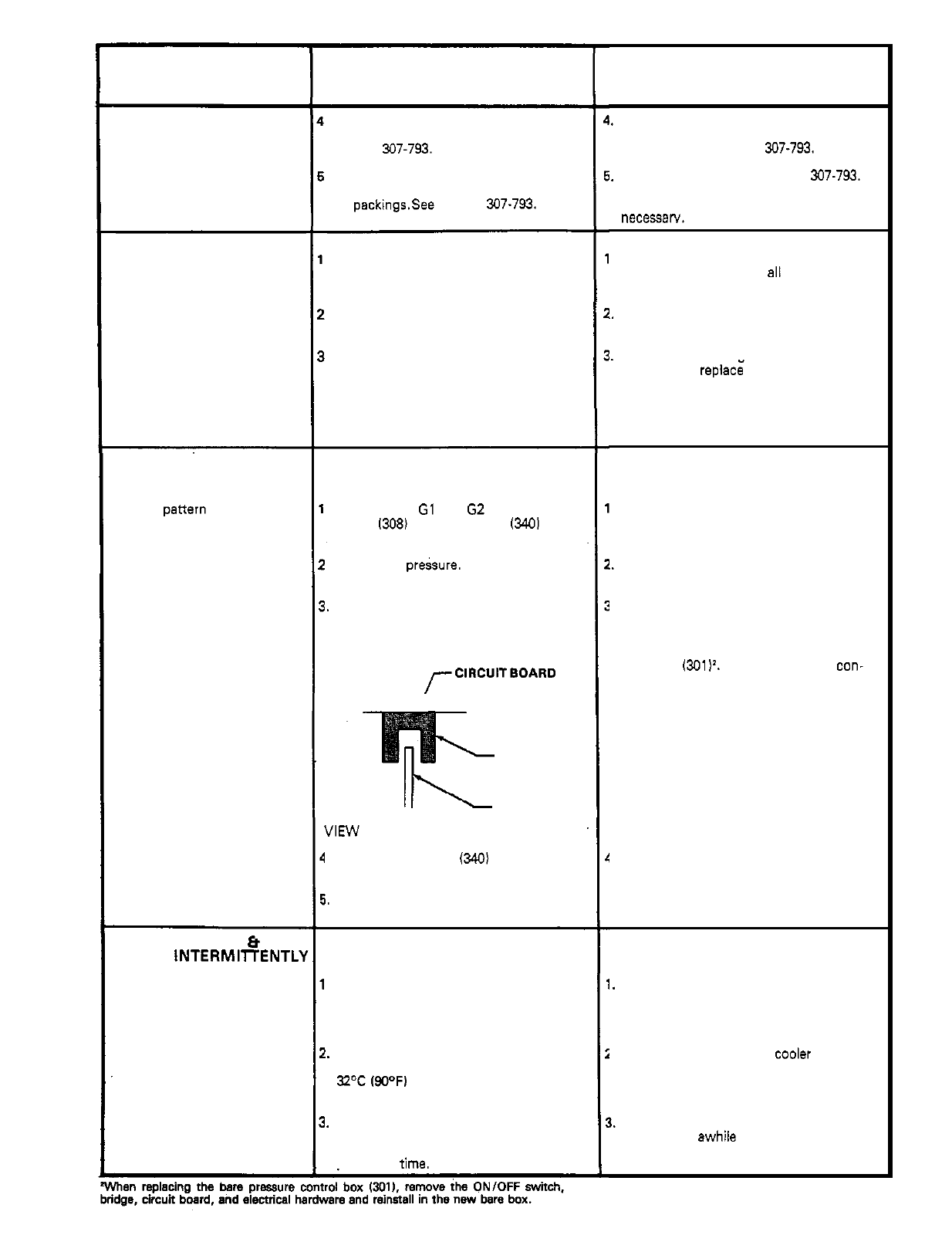

Be sure both G1 and G2 leads from

firmly

connected. See

page

22.

bridge

1308)

to circuit

board

13401

are

'.

Check stall pressure. Refer to Calibration

procedure on page 24.

i.

Check bourdon tube flag and detector

position. Turn pressure sening to max

-

imum; flag should not drag or bind

in

optical detector slot of circuit board.

r

CIRCU'TBoARD

OPTICAL

DETECTOR

"

OPTICAL

DETECTOR

FLAG

VIEW

OF OPTICAL DETECTOR AND FLAG

I.

Check circuit board

(3401

by substituting

with a good board. See page

22.

i.

Check

LOW

OUTPUT section on page

12.

.

Check to

see

if

sprayer has been

operating at high pressure with small

tips, which causes low motor RPM and

results

in

excessive heat build up.

I.

Check to

see

if ambient temperature

where sprayer is located is more than

32%

(90°F)

or

if

sprayer

is

located

in

direct sun.

!.

Check to

see

if

sprayer has been left in a

stalled condition [sprayer turned on,

pressurized, but not operating) for long

periods of

time.

WHAT TO

DO

If

check

is

NOT

OK

refer to this column

,.

Remove intake valve and clean. Check

balls and seats for nicks; replace if

necessary. See manual

307-793.

#.

Replace packings. See manual 307-793.

Also check piston valve seat for harden

-

ed

paint or nicks and replace

if

necessarv.

.

Replace pin if missing. Be sure retainer

spring is fully in groove

a11 around

connecting rod. See page 26.

!.

Replace connecting rod assembly. See

page 25.

i.

Check drive housino assemblv for

damage and

replac; if necessary.

See

page

25.

.

Reconnect securely. See page

22.

I.

Calibrate pressure control. See page 24.

I.

Carefully bend flag into alignment with

detector slot to see if that corrects pro

-

blem.

assembly

(3011'. Calibrate pressure con-

If not, replace bare pressure control

trol after reassembly.

I.

Replace circuit board. See page

22.

I.

Decrease pressure sening or increase

tip

size.

!.

Move sprayer

possible.

to shaded, coolel

'

area if

1.

Turn

off

sprayer whenever you stop

spraying for

awhile and relieve fluid

pressure.

307-671

13