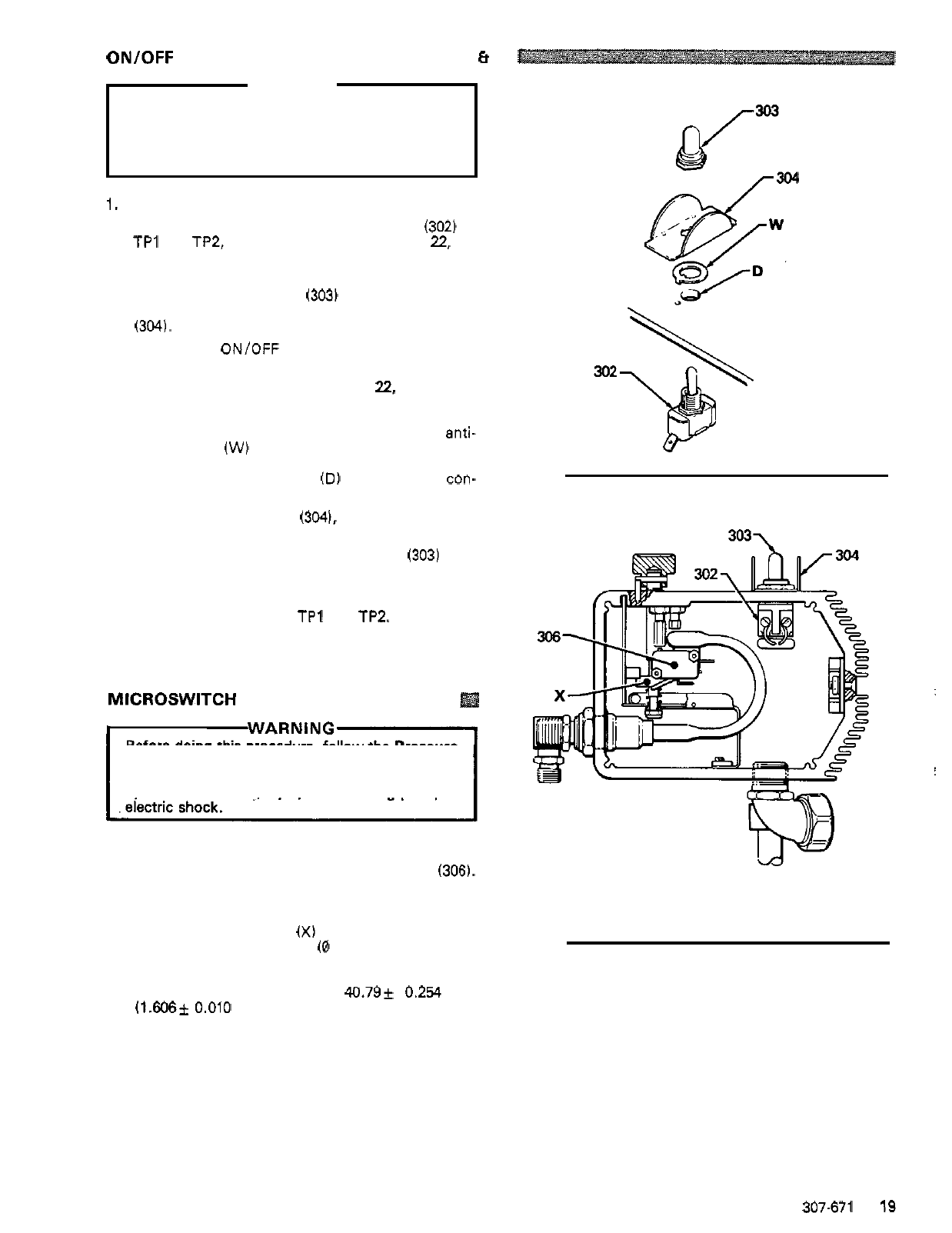

ON/OFF SWITCH REPLACEMENT

(See Figs 14

Et

WARNING

Before doing this procedure, follow the Pressure

Relief Procedure Warning on page 17 to reduce

the risk of

a

fluid injection injury, splashing

in

the

eyes or on the skin, injury from moving parts, or

electric

shock.

1. Remove the pressure control cover and screws.

2. Remove the wires attached to the switch

(302) at

TPl and TP2, using a screwdriver. See page

22,

Fig

21.

3.

Use a 16 mm socket wrench to loosen and remove

the nut and rubber boot

(303)

from the top of the

pressure control box. Remove the switch guard

(304).

4. Remove the ONIOFF switch.

5. Remove the wires attached to the switch TP4 and

TP3 using a screwdriver. See page

22,

Fig 21.

6. Attach the wires to TP4 and TP3 of the new switch.

7. Install the new switch

so

the internal tab of the anti-

rotation ring

(W)

engages with the vertical groove

engages

with

the blind hole

(D)

of the pressure con-

in

the threads of the switch, and the external tab

trol box.

8.

Install the switch guard (304). aligning the internal

tab with the groove

in

the threads.

9. Powder the inside of the rubber boot

(303)

with

talcum, then shake excess out of boot.

10. Install the nut and rubber boot and tighten.

11. Reconnect the wires to

TP1 and TP2.

12. Reinstall the pressure control cover and screws.

MICROSWITCH REPLACEMENT

(See Fig 15)

Before doing this procedure, follow the Pressure

the risk of a fluid injection injury, splashing

in

the

Relief Procedure Warning on page 17 to reduce

eyes or on the skin, injury from moving parts, or

1. Remove the pressure control cover and screws.

2. Disconnect both wires from the microswitch

(3061.

3. Use the socket wrench to remove the nuts from the

microswitch.

4. Check to see if the flag

(X)

is loose. If

it

is, be sure

the

fluid

pressure is

0

bar

(0

psi), then loosen the

two

6

mm hex nuts behind the microswitch. Adjust

the distance from the top of the flat to top inside

of

the pressure control box to 40.79k 0.254 mm

(1.606*

0.010

in.).

Tighten the screwsand recheck

the dimension. Refer to Fig 1.

5. Perform the

STALL

PRESSURE

CALIBRATION

on page 24 before regular operation of the sprayer.

6. Reinstall the cover

and

screws.

15)

Fig

14

Fig

15

307-671

19