-28-

Model G0773 (Mfd. Since 12/14)

Chuck Mounting

This lathe ships with the 3-jaw chuck installed.

This is a scroll-type chuck where all three jaws

move in unison when the chuck key is used.

The included 4-jaw chuck features independent

jaws, which are used for square or unevenly-

shaped stock, and to mount work that needs to be

adjusted to near zero total indicated runout.

The included faceplate has slots for T-bolts that

hold standard or custom clamping hardware. With

the correct clamping hardware, a faceplate offers

a wide range of uses, including machining non-

concentric workpieces, straight turning between

centers, off-center turning, and boring.

Never use spindle speeds faster than chuck

RPM rating or safe limits of your workpiece.

Excessive spindle speeds greatly increase

risk of workpiece or chuck being thrown

from machine with deadly force!

Installation &

Removal Device

Figure 21. Example of common device used

during chuck installation and removal.

Plywood Protection

Plate for Chucks

Installed by Hand

Place a piece of plywood over the bedways to pro-

tect them from damage if a chuck or other tooling

is dropped (see below).

This lathe is equipped with a D1-type spindle

nose. This type of spindle uses camlocks that are

adjusted with a chuck key to securely mount a

chuck or faceplate with repeatable precision and

ease.

Chuck Installation

To ensure accurate work, it is extremely important

to make sure the spindle nose and chuck mating

surfaces/tapers are clean. Even a small amount of

lint or debris can affect accuracy.

The chuck is properly installed when all camlocks

are tight, the spindle and chuck tapers firmly

lock together, and the back of the chuck is firmly

seated against the face of the spindle all the way

around—without any gaps.

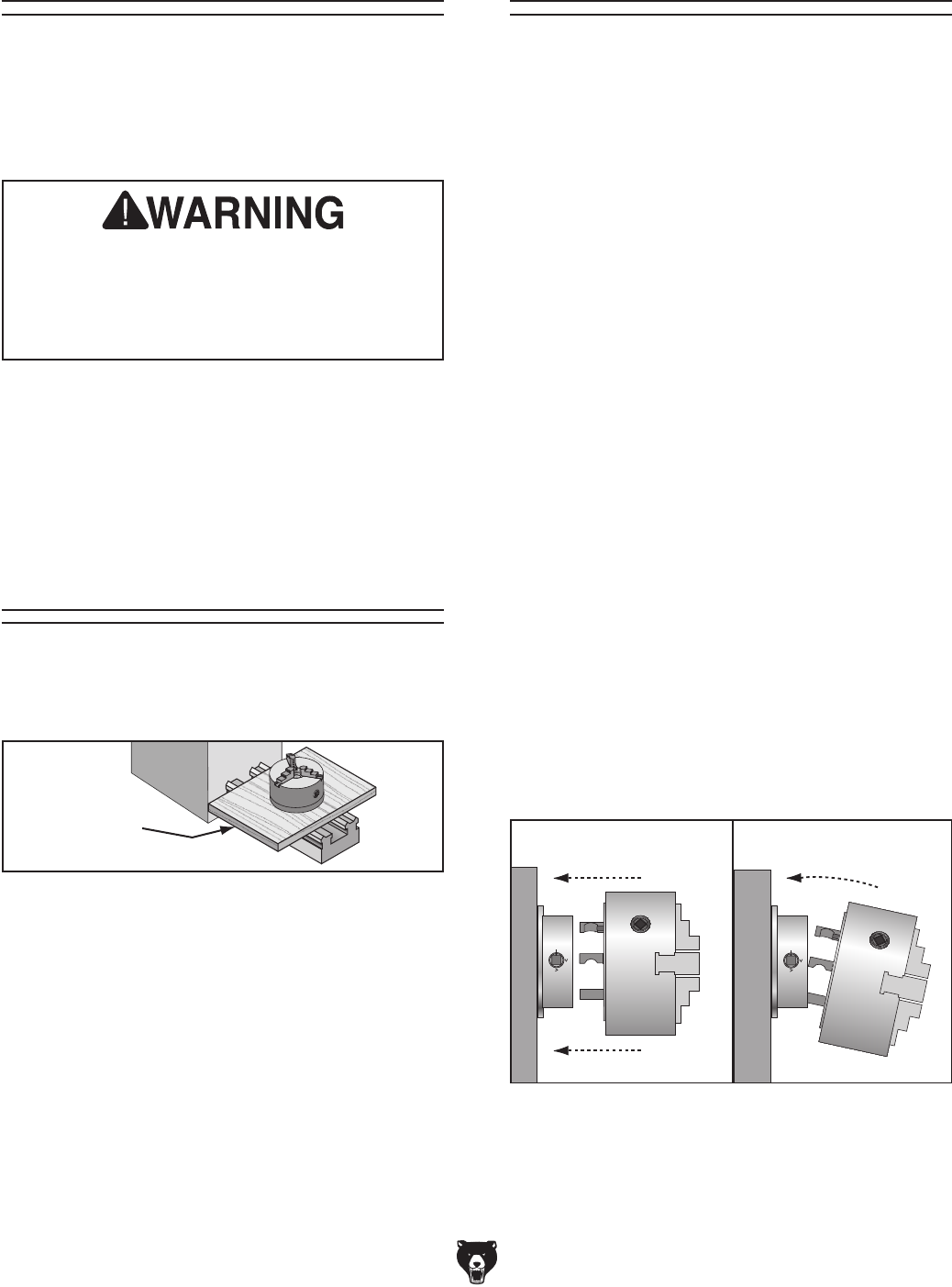

Figure 22. Inserting camlock studs into spindle

cam holes.

INCORRECTCORRECT

To install chuck:

1.

DISCONNECT LATHE FROM POWER!

2.

Use appropriate lifting, support, or protec-

tive device to protect ways and support

chuck during installation process (refer to

Installation & Removal Devices

section on

previous page).

3.

Clean and lightly oil camlock studs, then thor-

oughly clean mating surfaces of spindle and

chuck.

4.

Install chuck by inserting camlock studs

straight into spindle cam holes.

Important:

Avoid inserting the studs by piv-

oting them in from an angle or rotating the

spindle. This can damage studs or spindle

cam holes.