Model G0773 (Mfd. Since 12/14)

-41-

Spindle Speed

Cutting Speed (FPM) x 12

*Recommended

Dia. of Cut (in inches) x 3.14

Spindle

Speed

(RPM)

*Double if using carbide cutting tool

=

Figure 49. Spindle speed formula for lathes.

Determining Spindle Speed

Using the correct spindle speed is important for

getting

safe and satisfactory results, as well as

maximizing tool life.

To set the spindle speed for your operation, you

will need to: 1) Determine the

best

spindle speed

for the cutting task, and 2)

Configure the

lathe

controls to produce the required spindle speed.

Many variables affect the optimum spindle speed

to use for any given operation

,

but the two most

important are the recommended cutting speed for

the workpiece material and the diameter of the

workpiece, as noted in the formula shown below.

Cutting speed, typically defined in feet per minute

(FPM), is the speed at which the edge of a tool

moves across the material surface.

A recommended cutting speed is an ideal speed

for cutting a

type of material

in order to produce

the desired finish and optimize tool life.

The books

Machinery’s Handbook or

Machine

Shop Practice

, and some internet sites, pro-

vide excellent recommendations for which cutting

speeds to use when calculating the spindle speed.

The

se sources

also provide a wealth of additional

information about the variables that affect cutting

speed and

they are a good educational resource.

A

lso, there are a large number of easy-to-use

spindle speed calculators that can be found on

the internet.

These sources will help you

take into

account the applicable variables in order to deter-

mine the best spindle speed for the operation.

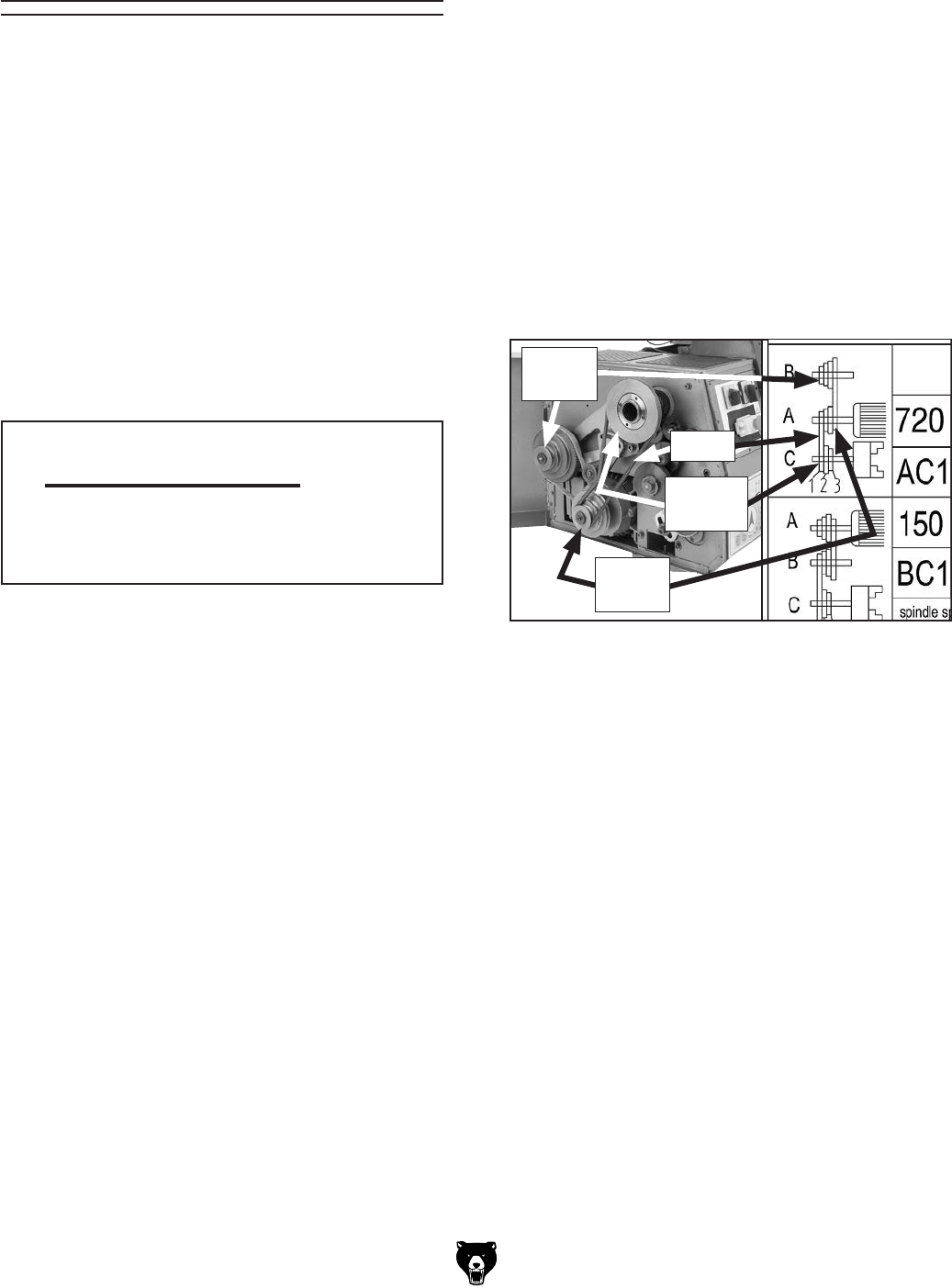

Setting Spindle Speed

Spindle speed is selected by positioning the

V-belt either between the spindle and motor pul-

leys (see Figure 50), or between the spindle and

idler pulleys. Select the motor pulleys for high

(720-2100 RPM) or idler pulleys for low (150–470

RPM) speed ranges. The V-belt diagram below is

also found on the headstock.

Refer to Tensioning & Replacing V-Belts on

Page 70 for instructions on removing and re-

installing V-belts.

Tool Needed Qty

Hex Wrench 4mm .............................................. 1

Figure 50. Belt positioned for 720 RPM.

V-Belt

Idler

Pulleys

Spindle

Pulleys

Motor

Pulleys