ELECTRICAL OUTPUT

CONNECTIONS

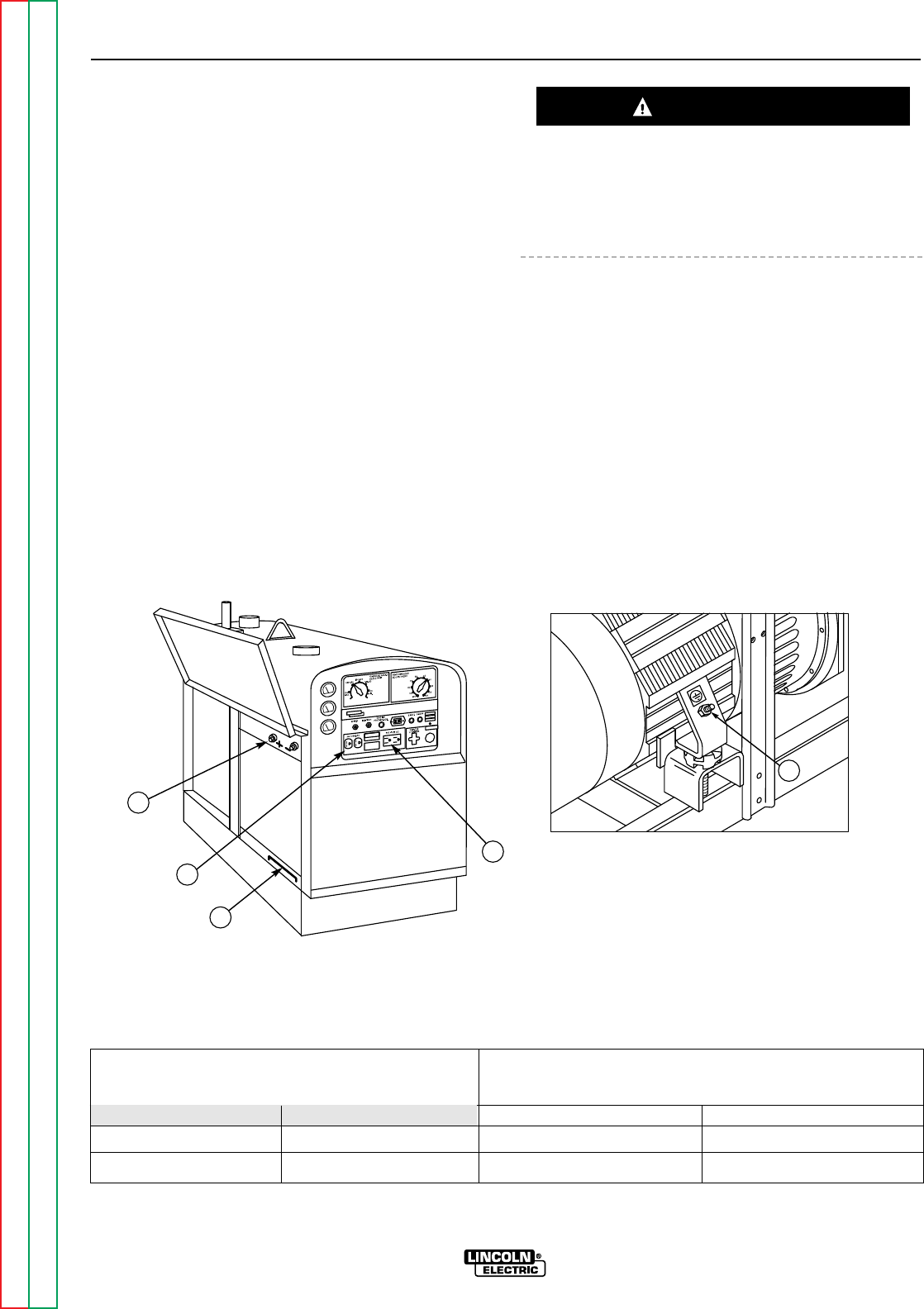

See Figure A.1 for the location of the 115 and 230 volt

receptacles, weld output terminals, and ground stud.

WELDING CABLE CONNECTIONS

CABLE INSTALLATION AND CABLE SIZES

With the engine off, route the electrode and work

cables through the strain relief bracket on the base and

connect to the terminals located on the fuel tank mount-

ing rail. (See size recommendations below.) For posi-

tive polarity, connect the electrode cable to the terminal

marked Positive (+). For Negative polarity, connect the

electrode cable to the Negative (-) terminal. These

connections should be checked periodically and tight-

ened if necessary.

• Loose connections will cause the output terminals to

overheat. The terminals may eventually melt.

• Do not cross the welding cables at the output terminal

connection. Keep the cables isolated and separate

from one another.

When welding at a considerable distance from the

welder, be sure you use ample size welding cables.

Table A.1 lists recommended cable sizes and lengths

for rated current and duty cycle. Length refers to the

distance from the welder to the work and back to the

welder. Cable diameters are increased for long cable

lengths to reduce voltage drops.

Lincoln Electric offers a welding accessory kit with the

properly specified welding cables. See the

Accessories

section of this manual for more

information.

INSTALLATION

A-6 A-6

SA-250

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CAUTION

3

1

5

2

4

FIGURE A.1 - SA-250 OUTPUT CONNECTIONS

1. 230 VAC RECEPTACLE

2. 115 VAC RECEPTACLE

3. OUTPUT TERMINALS

4. GROUND STUD

5. CABLE STRAIN RELIEF

TABLE A.1 - RECOMMENDED COPPER WELDING CABLE SIZE AND LENGTH

TOTAL COMBINED LENGTH OF ELECTRODE AND WORK CABLES

Cable sizes for combined length of

electrode plus work cable

Amps Duty Cycle Up to 200 ft. 200 to 250 ft.

250 60% 1 1/0

350 25% 2/0 3/0