Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

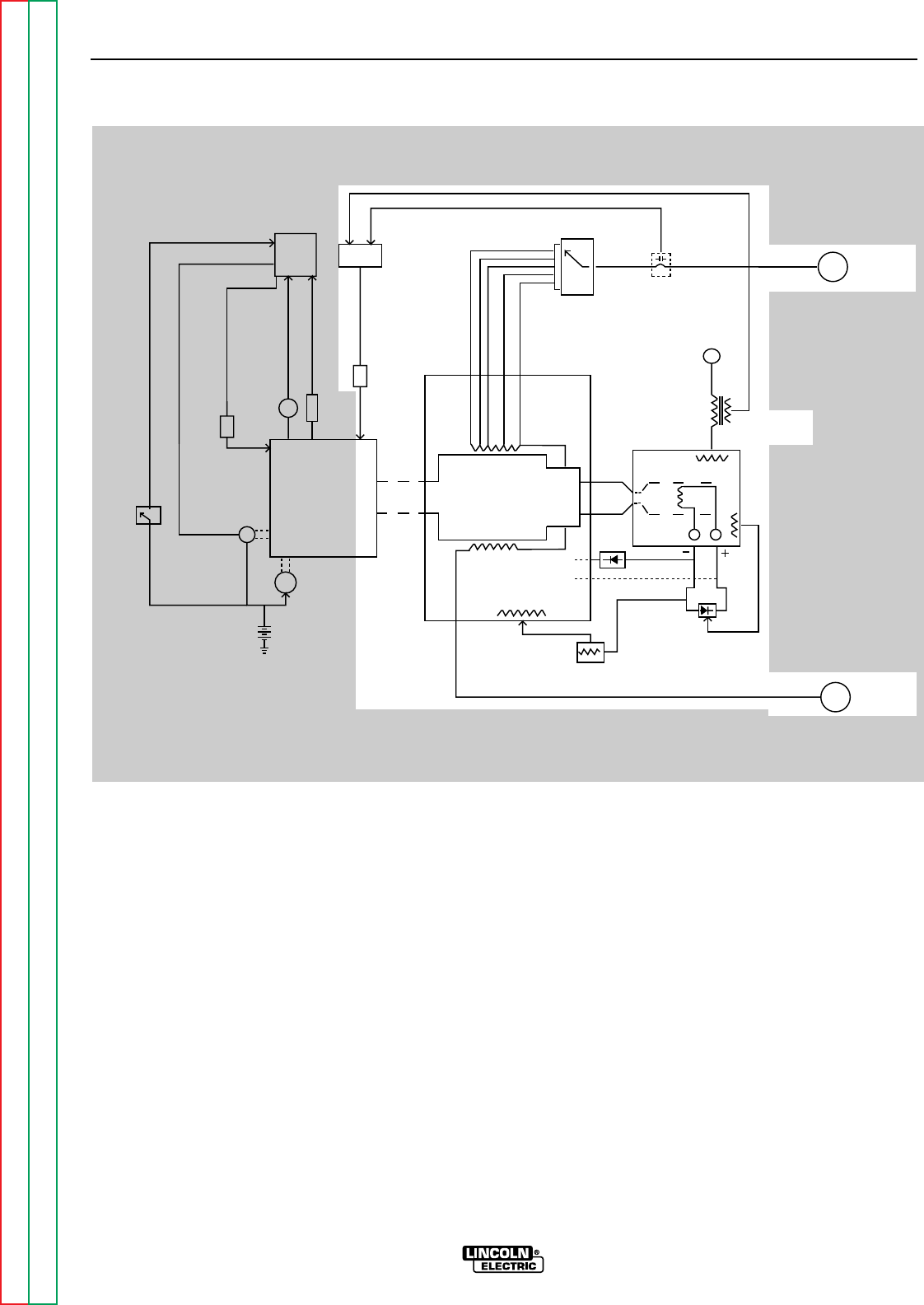

ENGINE, GENERATOR ARMATURE

AND FRAME, ALTERNATOR

STATOR AND ROTOR

EXCITATION (FLASHING)

When the engine is started and running, the residual

magnetism voltage is applied to the alternator rotor via

a brush and slip ring configuration. This excitation

(“flashing”) voltage magnetizes the rotor lamination.

The alternator rotor is connected to the armature shaft,

which is mechanically coupled to the engine. This

rotating magnet (rotor) induces a voltage in the station-

ary windings of the alternator stator.

AUXILIARY AND FIELD FEEDBACK COILS

There are two isolated windings incorporated in the sta-

tor lamination assembly. One of these windings is

tapped and provides 115VAC and 230VAC of auxiliary

power to the appropriate receptacles. The other

115VAC isolated winding is rectified to a DC voltage

and is used to supply field feedback voltage to the rotor.

It also, through the generator field rheostat control, sup-

plies voltage to the field shunt windings in the main

generator frame.

THEORY OF OPERATION

E-3 E-3

SA-250

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

FIGURE E.3 – ENGINE GENERATOR ARMATURE AND FRAME, ALTERNATOR STATOR AND ROTOR

NEGATIVE

OUTPUT

TERMINAL

POSITIVE

OUTPUT

TERMINAL

115 & 230VAC

RECEPTACLES

CURRENT

TRANSFORMER

FIELD

RECTIFIER

FLASHING

RESIDUAL

MAGNETISM

ALTERNATOR STATOR

ROTOR

SLIP

RINGS

ARMATURE

SHAFT

GENERATOR

ARMATURE

BRUSHES

&

COMMUTATOR

GENERATOR

FRAME

SERIES

COILS

INTERPOLE

COILS

SHUNT

WINDINGS

GENERATOR

FIELD CONTROL

FIELD

MECHANICAL

COUPLING

REED

RELAY

CR2

SELECTOR

SWITCH

IDLER

BOARD

IDLER

SOLENOID

OIL

PRESSURE

TEMPERATURE

FUEL

ENGINE

ALTERNATOR

STARTER

MOTOR

BATTERY

ENGINE

PROTECTION

RELAY

IGNITION

SWITCH

INJECTION

PUMP

GAUGE

SWITCH