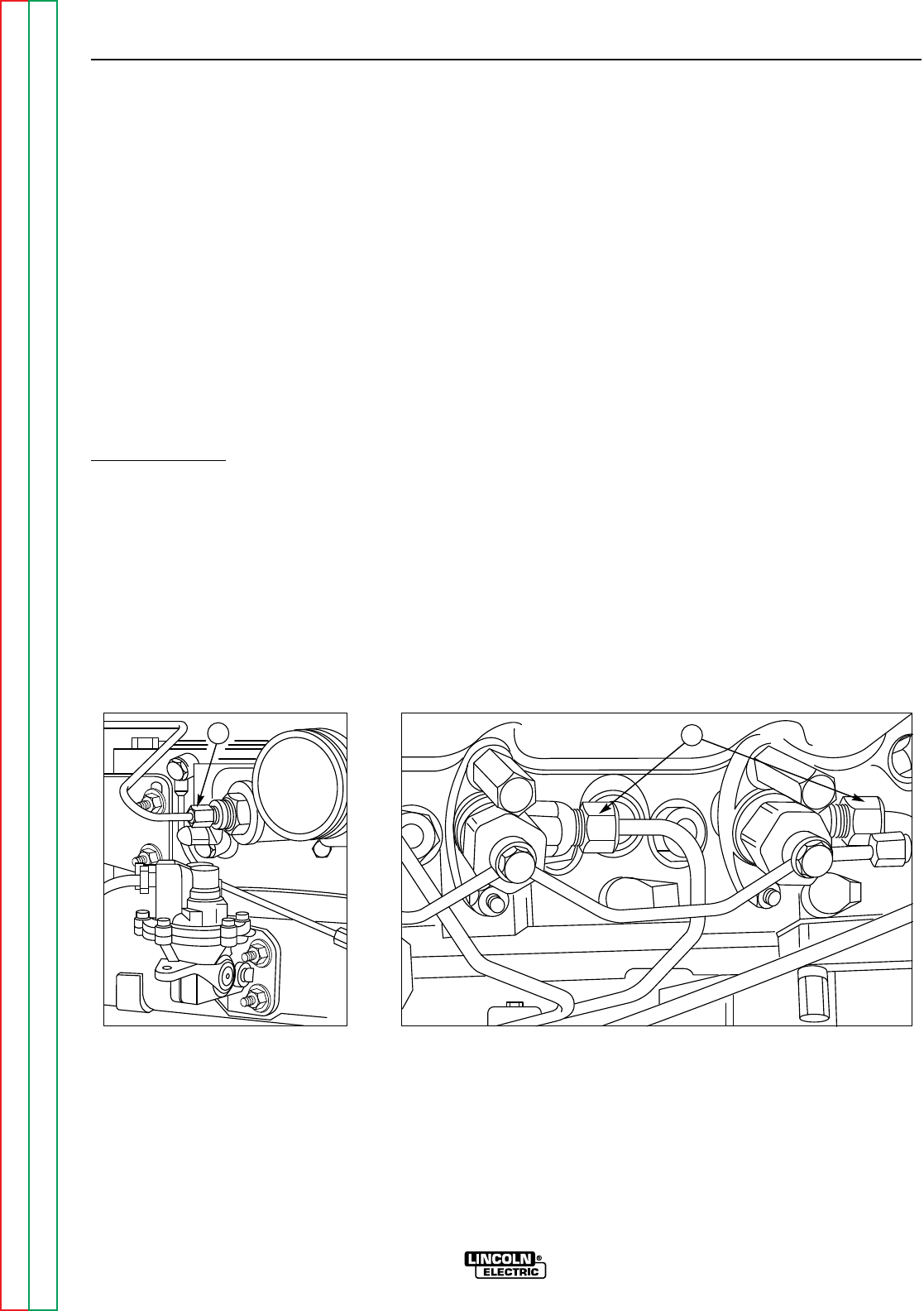

7. See Figure D.4. Loosen the union nut (1) at the

fuelled starting aid (if one is fitted) and operate the

lift pump until fuel, free from air, comes from the

connection. Tighten the union nut at the starting

aid.

8. See Figure D.4. Loosen the union nuts of the high-

pressure pipes (2) at two of the atomisers. Operate

the starter motor until fuel, free from air, comes from

the pipe connections. Tighten the high-pressure

pipe connections.

9. The engine is now ready to start. If the engine runs

correctly for a short time and then stops or runs

roughly, check for air in the fuel system. If there is

air in the fuel system, there is probably a leakage in

the low pressure system.

Self-vent method

If the engine has been stopped by air in the fuel sys-

tem:

Ensure that fuel has been added to the tank or that the

leakage has been corrected.

1. If a manual stop control is fitted, ensure that it is in

the “run” position.

2. Operate the starter motor until the engine starts.

If the system or a component in the system has been

drained:

1. Turn the start key to the “R” position. If a manual

stop control is fitted, ensure that it is in the “run”

position.

2. Operate the lever of the fuel lift pump slowly for

approximately two minutes. If the drive cam of the

fuel lift pump is at the point of maximum cam lift, it

will not be possible to operate the priming lever. In

this situation, the crankshaft must be turned one

revolution.

3. Operate the starter motor until the engine starts.

If the engine runs correctly for a short time and then

stops or runs roughly, check for air in the fuel system.

If there is air in the fuel system, there is probably a

leakage in the low pressure system.

MAINTENANCE

D-6 D-6

SA-250

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE D.4 – ELIMINATING AIR FROM THE FUEL SYSTEM

(continued)

1

2