Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

THEORY OF OPERATION

E-5 E-5

SA-250

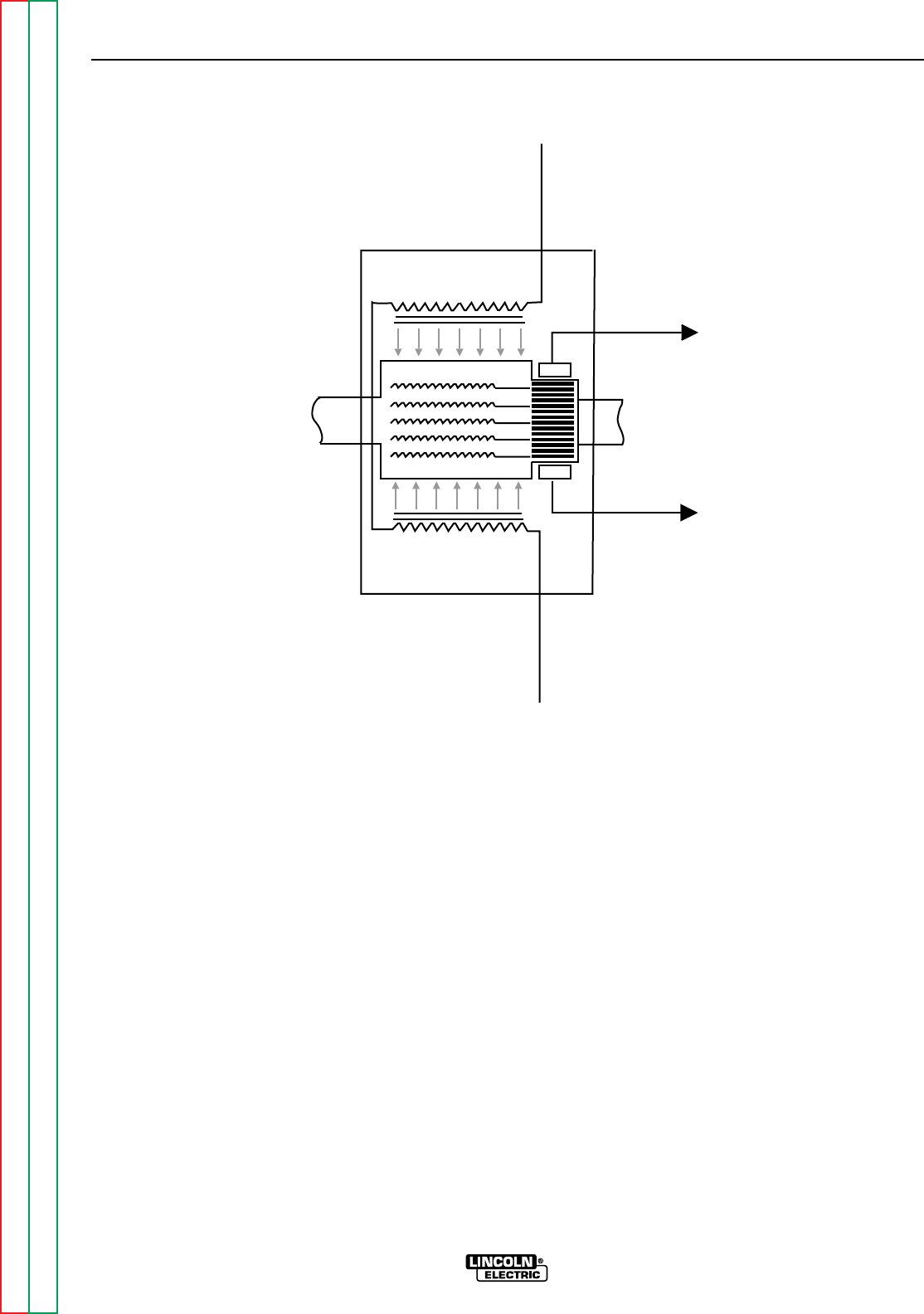

FIGURE E.4 – DC GENERATOR MACHINES

ARMATURE

SHAFT

GENERATOR

ARMATURE

SHUNT

WINDINGS

FIELD

MECHANICAL

COUPLING

SHUNT

WINDINGS

FIELD

B

RUSH

B

RUSH

MAGNETIC FIELD

MAGNETIC FIELD

DC CURRENT

DC CURRENT

F

I

E

L

D

C

U

R

R

E

N

T

F

I

E

L

D

C

U

R

R

E

N

T

DC GENERATOR MACHINES

The armature winding of a DC generator is located on

the rotating member. Current is conducted from it by

means of carbon brushes. The field winding is located

in the stator, which is stationary, and is excited by direct

current.

The armature coil sides are placed at opposite points

on the rotating shaft with the conductors parallel to the

shaft. The armature assembly is normally turned at a

constant speed by a source of mechanical power con-

nected to the shaft. Rotation of the armature through

the magnetic field produced by the stationary field

winding induces a coil voltage in the armature winding.

The voltage induced in an individual armature coil is an

alternating (AC) voltage, which must be rectified. In a

conventional DC Generator, rectification is provided

mechanically by means of a commutator. A commuta-

tor is a cylinder formed of copper segments insulated

from each other and mounted on, but insulated from,

the rotating shaft. Stationary carbon brushes held

against the commutator surface connect the armature

windings to external terminals. The commutator pro-

vides full-wave rectification, transforming the voltage

waveform between brushes and making available a DC

voltage to the external circuit.