THEORY OF OPERATION

E-4 E-4

RANGER® 3 PHASE

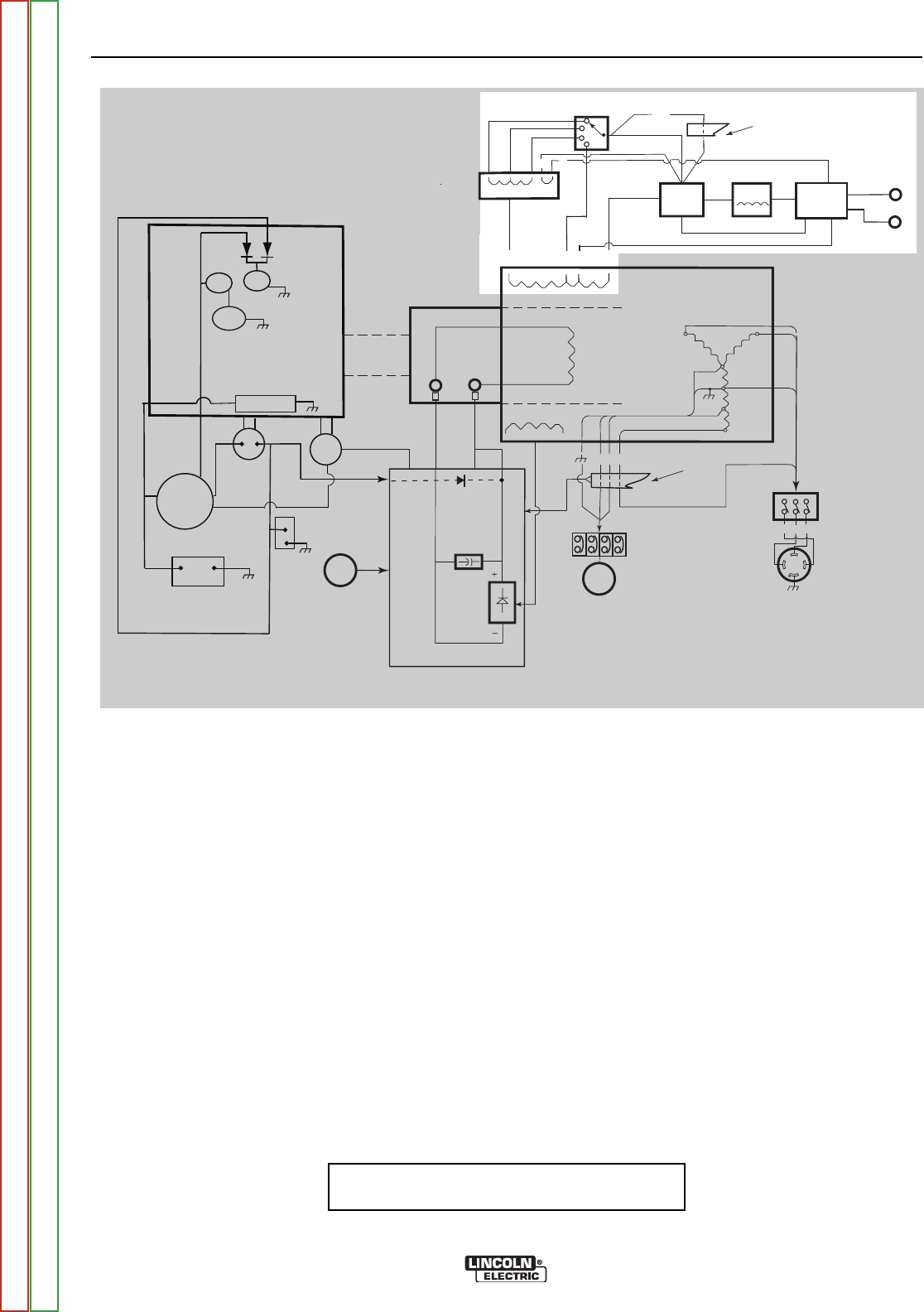

FIGURE E.2 - WELD CIRCUITRY

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

WELD CIRCUITRY

One end of the Weld Winding is connected to the

Output Rectifier and at the other end to the Reactor.

There are taps (C1) for constant voltage (CV) welding

and (WAC) for AC welding.

The Reactor Winding is tapped winding to provide the

three constant current (CC) welding ranges. As current

is drawn through the reactor it causes the voltage out-

put of the machine to drop off. This action creates the

“drooping” output characteristic that is required for stick

and TIG welding. The C1 tap does not go through the

reactor so there is very little “droop” as the weld current

is increased. It is used to provide the constant voltage

(CV) output that is required for wire welding.

The Polarity Switch is used to select the desired weld

mode — DC+, DC- or AC. It connects either the AC out-

put or the proper side of the rectified output to the

WORK and ELECTRODE terminals.

In AC weld mode, the weld current is routed through

another winding in the Reactor (S2 to E) in order to

improve weld characteristics.

When DC output is selected, the AC weld current is fed

to the Output Rectifier to be converted to DC. The

positve output of the rectifier is then routed through the

Choke to smooth out the ripple and provide good weld-

ing characteristics.

Lead #254 is a sense lead that is connected in parallel

to the lead from the Range Switch to the AC side of the

rectifier and as a result shares a portion of the weld cur-

rent. It is routed through the toroid to activate the Idler

Circuit when weld current is present.

IDLER

SOLENOID

OUTPUT

CONTROL

MECHANICAL

ROTATION

FIELD

CAPACITOR

SLIP

RINGS

RANGE

SWITCH

OUTPUT

BRIDGE

CHOKE

AC

AC

WORK

TERMINAL

PRINTED CIRCUIT

BOARD

TOROIDTOROID**

ENGINE

FLYWHEEL ALTERNATOR/

VOLTAGE REGULATOR

BATTERY

HOUR

METER

OIL

PRESSURE

SWITCH

+

-

STARTER

FUEL

SHUTOFF

SOLENOID

STARTER

SOLENOID

ENGINE

CONTROL

SWITCH*

4

3

2

1

ZY

3

5

6

X

120 & 230 VOLT

BREAKERS AND

RECEPTACLES

EXCITER

WINDING

AUXILIARY

WINDINGS

WELD WINDINGS

Z X Y

480 VOLT 3 PHASE

BREAKER AND

RECEPTACLE

W2

C1

W1

TOROIDTOROID**

254

3 6 X

*

Lead 254 - 1 turn through the toroid

Leads 3 & 6 - two turns through the toroid in opposite directions.

Lead X passes though the toroid in the same direction as lead 6

STATOR

+

--

ELECTRODE

TERMINAL

POLARITY

SWITCH

ROTOR

FLASHING

DIODE

E

S2

WAC

REACTOR

7 9

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC