I

I

merit.

IMPORTANT

U

U

NOTE

I

SECTION

3

-

INSTALLATION

3

-

1.

LOCATION

(Figure

3-1)

A

proper

installation

site

should

be

selected

for

the

welding

generator

if

the

unit

is

to

provide

dependable

service,

and

remain

relatively

maintenance

free.

I

F~O~TANT

II

this

welding

generator

is

to

be

mounted

on

a

trailer

(optional),

enture

that

the

engine

end

is

mounted

toward

the

front

(hitch

end)

of

the

trailer

to

maintain

proper

weight

distribution.

Also

ensure

that the

torque

weight

of

the

trailer

is

5

to

10%

of

the

gross

vehicle

weight.

It is

recommended

that

a

properly

fitting

canvas

cover

(optional)

be

placed

over

the

welding

generator

when

not

in

operation

to

protect

the

unit

from

the

environment.

L

CAUTION

U

If

this

unit

is

to

be

operated

indoors,

it

should

be

located

in

a

place

where

the

exhaust

fumes

from

the

engine

can

be

vented

out

of

the

building.

Failure

to

comply

with

proper

venting

may

result

in

stjrious

bodily

injury

or

loss

of

life.

;~=ANT;

I

The

engine

exhaust

system

on

this

welding

generator

has

not

been

equipped

with

a

spark

arrestor

unless

it

was

specifically

ordered

as

an

optional

accessory.

A

spark

arrestor,

maintained

in

effective

working

order,

is

mandatory

if

this

welding

generator

is

to

be

operated

in

a

National

Forest,

or

on

California

Grasslands,

brush,

or

forest

covered

land

(see

Section

4442

of

California

Public

Resources

Code).

For

other

areas,

check

your

state

and

local

laws.

A

proper

installation

site

permits

freedom

of

air

movement

into

and

out

of

the

welding

generator,

and

also

least

subjects

the

unit

to

dust,

dirt,

moisture,

and

corrosive

vapors.

A

minimum

of

18

inches

of

unrestricted

space

must

be

maintained

between

the

welding

generator

front

and

rear

panels

and

the

nearest

obstruction.

Also,

the

underside

of

the

welding

generator

muss

be

kept

completely

free

of

ob

structions.

The

installation

site

should

also

permit

easy

removal

of

the

outer

enclosure

for

maintenance

functions.

Do

not

place

any

filtering

device

over

the

intake

air

passages

of

the

welding

generator

as

this

would

restrict

the

volume

of

intake

air

and

thereby

subject

the

internal

components

to

an

overheating

condition

and

subsequent

failure.

Warranty

is

void

if

any

type

of

filtering

device

is

used.

On

most

welding

generators

a

lifting

device

is

provided

for

moving

the

unit.

However,

if

a

fork

lift

vehicle

is

used

for

lifting

the

unit,

be

sure

that

the

lift

forks

are

long

enough

to

extend

completely

under

base.

of

lift

f

short

e

xte

nd

o

ut

of

the

opposite

side

of

the

base

will

expose

internal

compon

ents

to

damage

should

the

tips

of

the

lift

forks

pene

trate

the

bottom

of

the

unit.

3-2.

WELD

OUTPUT

CONNECTIONS

(Figure

3-2)

To

obtain

the

full

rated

output

from

this

unit,

isis

necessary

to

select,

install,

and

maintain

proper

welding

cables.

Failure

to

comply

in

any

of

these

areas

may

result

in

less

than

satisfactory

welding

performance.

Ensure

that

the

unit

is

completely

~own

before

~iaking

any

weld

output

connections.

1

A.

Location

The

POSITIVE

and

NEGATIVE

weld

output

terminals

are

located

on

the

lower

portion

of

the

front

panel.

Open

the

lower

front

access

door.

Route

the

weld

cables

between

the

two

horizontal

pieces

of

angle

iron

on

the

front

of

the

base

(see

Figure

3-2)

and

connect

the

cables

to

the

weld

output

terminals.

Secure

the

lower

access

door.

Under

this

heading,

installation,

operating,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

nay

result

in

damage

to

equip-

Under

this

heading,

explanatory

statements

will

be

found

that

need

special

emphasis

to

obtain

the

most

efficientoperation

of

the

equipmrrnt.

I

I

I

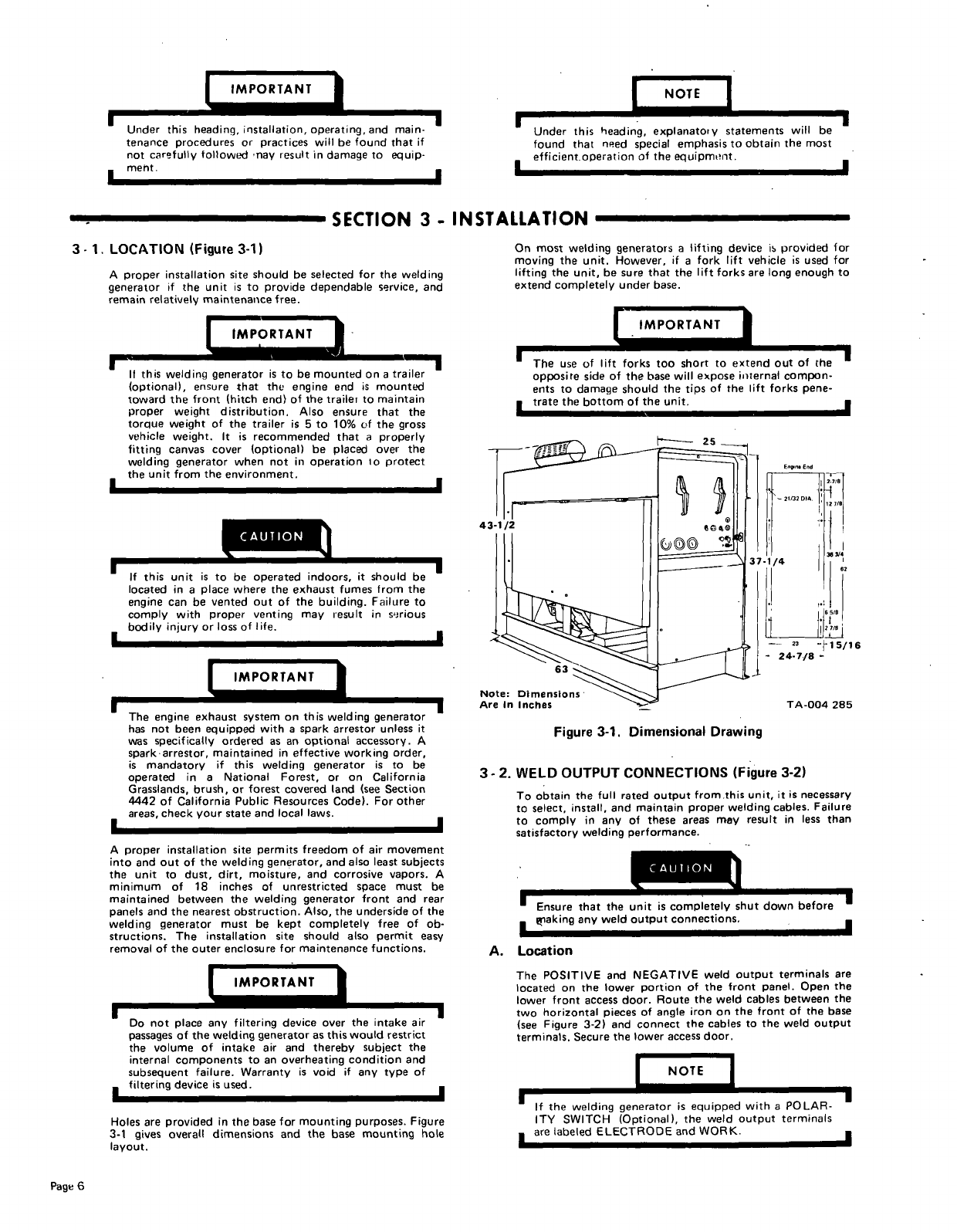

Figure

3-1.

Dimensional

Drawing

TA-004

285

U

U

I

I

Holes

are

provided

in

the

base

for

mounting

purposes.

Figure

3-1

gives

overall

dimensions

and

the

base

mounting

hole

layout.

NOTE

If

the

welding

generator

is

equipped

with

a

POLAR

ITY

SWITCH

(Optional),

the

weld

output

terminals

i

are

labeled

ELECTRODE

and

WORK.

1

Page

6