The

air

intake

to

the

air

cleaner

is

equipped

with

a

selector

tube

which

allows

the

air

to

be

drawn

either

from

the

sur

rounding

engine

compartment

air

or

heated

air,

drawn

from

around

the

exhaust

manifold

of

the

engine.

Heated

air

will

prevent

carburetor

icing

in

cold

weather.

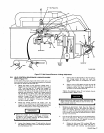

Figure

9-5

shows

the

selector

tube

in

the

cold

weather

operating

position.

When

the

tube

is

in

this

position,

it

must

remain

about

1

/2S

away

from

the

air

cleaner

inlet.

For

warm

weather

operation,

loosen

the

selector

tube

and

slide

it

all

the

way

down

against

the

manifold

and

re-tighten.

9-8.

AIR

CLEANER

SERVICE

(Figure

9-6)

A.

Daily

Service

1.

Open

the

engine

compartment

door

nearest

the

air

clean

er.

2.

Make

certain

that

the

screen

on

the

weather

cap

is

free

of

dirt

and

foreign

material.

B.

Weekly

Service

Service

paper

element

once

every

week

under

normal

condi

tions

or

when

loss

of

power

is

noted.

Servicing

element

is

accomplished

in

the

following

manner:

1.

Remove

filter

element

lock

assembly

and

seal.

2.

Inspect

the

gasket

on

the

end

of

the

element

for

damage.

Wipe

Out

inside

of

air

cleaner

housing

before

installing

element.

Do

not

use

the

element

if

the

gasket

is

demaged

or

missing.

3.

It

is

recommended

that

the

element

should

be

replaced

after

ten

washings

or

at

the

end

of

the

season,

whichever

comes

first.

NOTE

When

it

becomes

necessary

to

service

the

air

cleaner

in

the

field,

follow

the

procedure

outlined

in

Figure

9-6.

It

is

recommended

that

a

spare

element

always

be

kept

on

hand

for

replacement.

New

elements

are

available

from

your

distributor.

5.

Shake

out

excess

water

from

the

element

and

allow

to

air

dry.

Compressed

air,

not

to

ex

ceed

100

lbs.

of

pressure

can

clean

the

element.

In

sert

nozzle

inside

the

ele

ment

and

blow

out

dust.

Clean

dust

from

the

out

side

of

the

element

by

holding

the

nozzle

at

least

6

inches

from

the

ele

ment.

Figure

9.6.

Air

Cleaner

Service

U

I

I

U

For

a

temporary

expedient

in

the

field,

the

element

.can

be

cleaned

by

tapping

the

side

or

the

end

care

fully

against

the

palm

of

the

hand.

CAUTION:

Do

not

tap

ele

ment

against

a

hard

surface.

The

element

may

be

damaged

by

doing

so.

If

compressed

air

is

not

available,

or

if

soot,

oily

vapor,

or

any

dirt

is

pres

ent

which

cannot

be

re

moved

by

compressed

air,

then

the

element

is

to

be

washed.

Agitate

element

in

warm

water

containing

a

non-sudsing

detergent.

Reverse

flush

with

clean

water

to

thoroughly

rinse

all

loosened

foreign

ma

terial

from

the

filter.

CAUTION:

Do

not

use

water

hotter

than

the

hand

can

stand;

solvents

or

oil;

fuel

oil,

or

gasoline.

CAUTION:

Do

not

attempt

to

remove

excess

water

by

using

compressed

air.

6.

An

even

fine

pattern

of

light

through

the

element,

when

a

light

is

held

inside

the

element,

indicates

that

the

element

is

clean.

Any

large

spot

of

light

in

dicates

that

the

element

is

dam

aged

and,

therefore,

is

unfit

for

further

use.

Replace

the

element.

To

minimize

down

time,

created

by

waiting

for

the

element

to

dry,

it

is

suggested

that

the

newly

cleaned

filter

be

replaced

by

a

similar

standby

unit.

TA-900

716-7

Page

16