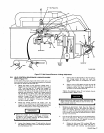

A

See

Figure

9-4

9-9.

IDLE

CONTROL/GOVERNOR

LINKAGE

ADJUST

MENT

(Figure

9-7)

in

the

event

that

proper

engine

idle

and/or

weld

rpm

is

not

being

attained,

perform

the

following

procedures

to

calibrate

the

engine

for

proper

idle

and

weld

rpm:

1.

Adjust

the

length

of

the

governor

linkage

(item

1,

Figure

9-7)

so

that

the

throttle

stop

plate

(2)

is

about

1/32

from

the

stop

(3).

To

adjust

the

linkage

(1),

loosen

the

linkage

securing

nuts

(5)

and

remove

the

hardware

(6)

securing

the

linkage

socket(s)

(4)

to

the

governor

and

carburetor.

Rotate

the

linkage

socket(s)

(4)

accordingly

to

obtain

the

1/32

gap.

Clockwise

rotation

of

the

linkage

socket(s)

)4(

will

shorten

the

governor

linkage

(1)

and

thus

reduce

the

gap.

Con

versely,

counterclockwise

rotation

of

the

linkage

socket)s)

(4)

will

lengthen

the

governor

linkage

)1)

and

thus

increase

the

gap.

2.

Rotate

the

linkage

socket(s)

)4)

slightly

until

the

sockets

(4)

are

parallel

but

in

opposite

directions

with

respect

to

each

other.

Secure

the

linkage

socket

nuts

(5)

to

lock

the

position

of

the

linkage

socket(s)

(4).

~thelinkage~edomofmovement

throughout

its

entire

travel.

If

the

linkage

)1)

is

bind

ing

due

to

the

linkage

socket(s)

(4)

being

cocked

relative

to

each

other,

repeat

Step

2.

A.

Position

the

arm

(8)

laterally

so

that

the

carbur

etor

linkage

socket

(4)

does

not

touch

the

throttle

stop

plate

(2)

throughout

its

entire

travel.

B.

Position

the

arm

(8)

radially

so

that

the

arm

(8)

travels

an

equal

distance

to

either

side

of

an

imaginary

center

line

drawn

perpendicular

to

the

center

of

the

throttle

shaft

(9).

Tighten

the

alignment

screw

(7)

and

recheck

the

ad

justments

made

in

Steps

1

and

2.

sta

rti~7

t

he

e

ngine

and

while

wo

r

ki

ng

on

t

he

engine,

ensure

that

body

limbs

are

clear

of

the

fan

and

of

the

vacuum

motor

unit.

4.

Recheck

all

connections

made

thus

far.

Place

the

IDLE

CONTROL

switch

in

the

LOCK

OUT

position.

Start

the

welding

generator

engine

and

allow

the

engine

to

reach

normal

operating

temperature

(about

five

minutes).

Ensure

that

the

CHOKE

control

is

push

ed

fully

in

at

this

time.

5.

Pull

the

arm

(8)

toward

the

front

of

the

welding

gener

ator

to

the

idle

position.

Maintain

pressure

on

the

arm

(8)

to

butt

the

idle

screw

(10)

against

the

stop

(3)

throughout

the

following

adjustments:

A.

Rotate

the

idle

screw

(10)

to

obtain

400

rpm.

Clockwise

rotation

of

the

screw

(10)

will

in

crease

engine

rpm

whereas

counterclockwise

(2

1

'

10

~

Figure

9-7.

Idle

Control/Governor

Linkage

Adjustment

TC-003

226

I

I

3.

Loosen

the

alignment

screw

(7)

and

position

the

arm

(8)

radially

and

laterally

until

the

following

conditions

are

simultaneously

met:

OM-457

Page

17