Figure

3-4.

AC

Power

Curve

For

120/240

Volts

AC

Terminals

SECTION

4

-

ENGINE

PREPARATION

1

Fl

F

I

See

the

Engine

Manufacturers

manual

(F-i

63

Engine)

for

complete

engine

care.

4-1.

LUBRICATION

This

engine

was

shippAd

from

the

factory

with

its

crankcase

filled

with

the

correct

amount

and

type

of

break-in

oil

unless

otherwise

ordered.

Check

the

oil

level

before

attempting

to

operate

the

engine.

It

should

be

up

to

the

FULL

mark

on

the

bayonet

type

indicator.

Add

a

quality

brand

of

oil

if

the

oil

level

is

low.

See

the

oil

selection

chart,

Table

9-1,

in

Section

9.

Figure

4-1.

Oil

Level

Indicator

L–~RTANT~

I

New

engines

have

very

close

clearance

between

their

moving

parts.

Thus,

it

is

recommended

that

loading

of

the

engine

be

kept

to

a

minimum

during

the

first

50

hours

of

operation.

Be

sure

to

check

the

oil

level

several

times

each

day

during

the

engine

break-in

period.

This

engine

requires

about

50

hours

of

running

time

before

it

will

be

fully

broken

in.

After

about

50

hours

of

running

time,

drain

the

break-in

oil

and

change

the

oil

filter.

See

the

oil

selection

chart,

Table

9-1,

in

Section

9

for

correct

oil

type

and

grade

to

use

after

the

break-in

oil

is

drained.

The

liquid

capacity

of

the

coolant

system

in

this

welding

generator

is

9

quarts

(U.S.

Measure).

This

unit

is

shipped

from

the

factory

with

the

proper

amount

of

water

and

anti

freeze

to

permit

operation

of

the

unit

at

temperatures

down

to

0F.

I

. .

~i~RTANTI

-

1

If

this

welding

generator

is

to

be

operated

in

tem

peratures

which

are

below

0F,

additional

anti-freeze

will

have

to

be

added

to

the

coolant

system

or

the

liquid

in

the

system

will

freeze

and

thus

cause

the

engine

to

overheat.

I

I

The

coolant

system

is

equipped

with

a

180F

thermostat.

If

the

thermostat

should-become

defective,

be

sure

the

replace

ment

is

of

equal

temperature

rating.

Do

not

run

the

engine

with

a

defective

thermostat

or

without

one.

If

this

is

done,

the

engine

will

run

cold

and

develop

excess

carbon

accumulation

and

the

oil

will

become

contaminated

with

excessive

sludge

and

dirt.

I

The

radiator

for

this

engine

is

equipped

with

a

pressurized

cap

which

is

rated

at

7

psi.

If

this

cap

is

ever

replaced,

ensure

that

the

replacement

cap

has

a

rating

of

7

psi.

~on

a

hou

Id

be

ax

ercised

at

all

times

wi~en

re

moving

the

radiator

pressure

cap.

The

cap

will

turn

to

an

almost

full

open

position,

at

which

point

a

pro

vision

has

been

made

to

permit

veuiting

built

up

pres

sure

within

the

radiator.

Allow

the

pressure

to

escape

before

completely

removing

the

cap

from

the

radiator

neck.

When

removing

the

cap,

it

is

recommended

that

-

a

glove

or

rag

be

used

to

protect

the

operators

hand

from

possible

exposure

to

extremely

hot

coolant.

PREPARING

NEW

BATTERY

FOR

SERVICE

Wet

Charged

Battery

The

wet

charged

battery

is

shipped

with

the

electrolyte

solu

tion

added

and

normally

in

an

operational

status.

However,

due

to

long

periods

of

idleness,

the

battery

may

become

weak

and

thus

require

charging.

The

battery

should

have

a

specific

gravity

reading

of

1.260

(at

80F)

before

operation.

If

this

level

is

not

present

when

it

is

to

be

used,

charge

the

battery

as

instructed

in

Section

4-3A,

step

4.

m

I

I

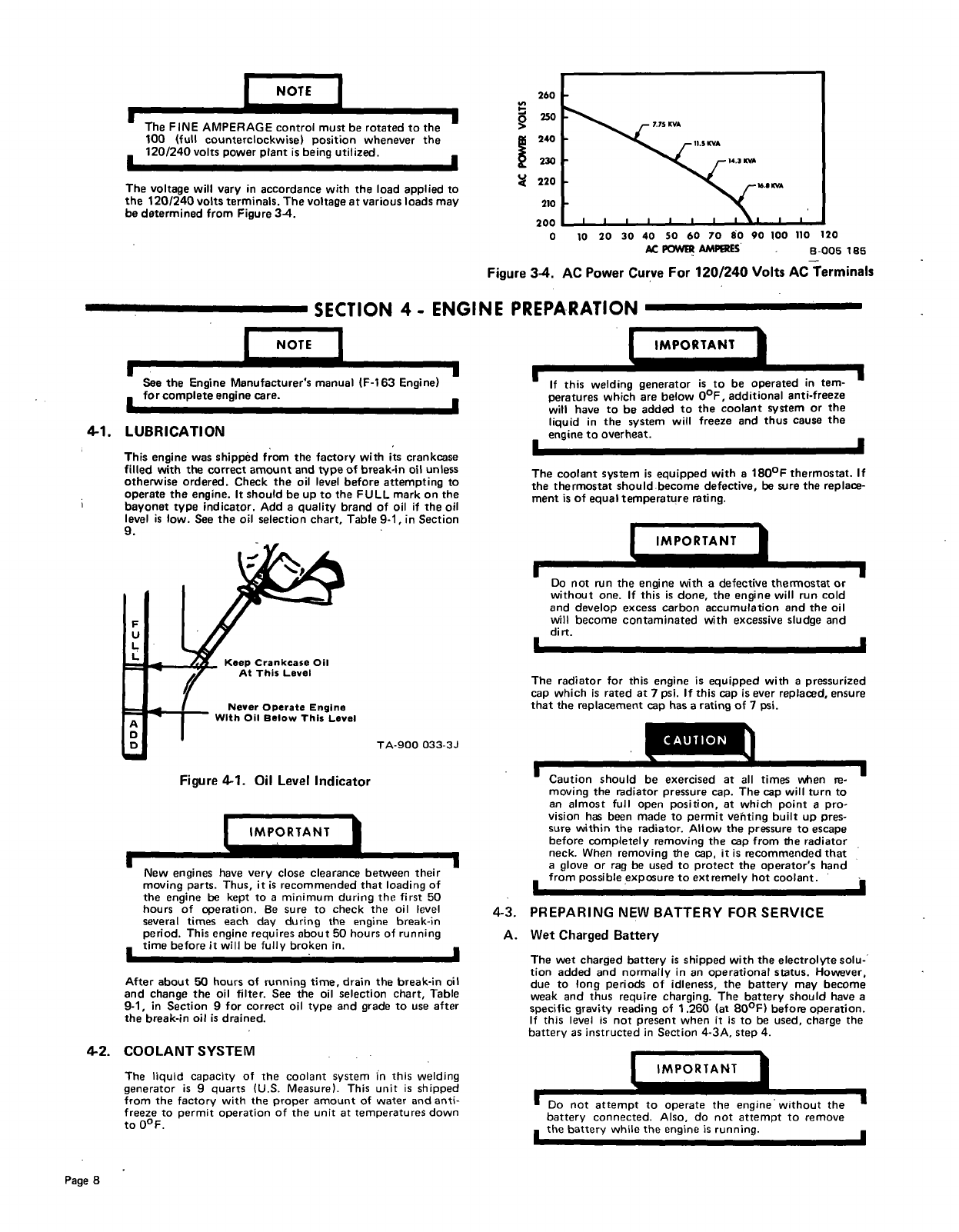

The

FINE

AMPERAGE

control

must

be

rotated

to

the

100

(full

counterclockwise)

position

whenever

the

120/240

volts

power

plant

is

being

utilized.

I

I

The

voltage

will

vary

in

accordance

with

the

load

applied

to

the

120/240

volts

terminals.

The

voltage

at

various

loads

may

be

determined

from

Figure

3-4.

260

U,

250

7.7SKVA

I.SKVA

240

230

14.3

KVA

~

220

~

16.1

KVA

210

200

0

10

20

30

40 50

60

70

80

90

100

110

120

~

POWER

.MPERES

8-005

185

Keep

Crankcase

Oil

At

This

Level

U

Never

Operate

Engine

With

Oil

Below

This

Level

TA-900

033-3.1

I

I

4-3.

A.

4-2.

COOLANT

SYSTEM

IMPORTANT

Do

not

attempt

to

operate

the

engine

without

the

battery

connected.

Also,

do

not

attempt

to

remove

the

battery

while

the

engine

is

running.

Page

8