show

the

minimum

and

maximum

curves

of

each

coarse

range.

When

the

FINE

AMPERAGE

control

is

adjusted,

the

volt-ampere

curve

will

fall

between

the

minimum

and

maximum

curves

of

the

particular

coarse

range

in

use.

5

-

6.

DUTY

CYCLE

(Figure

54)

The

duty

cycle

of

a

welding

generator

is

the

percentage

of

a

ten

minute

period

that

a

welding

generator

can

safely

be

operated

at

a

given

output.

This

welding

generator

is

rated

at

100

percent

duty

cycle.

This

means

that

the

welding

generator

can

be

safely

operated

at

rated

load

continuously.

If

the

welding

amperes

are

increased

beyond

rated

output,

the

duty

cycle

will

decrease.

Figure

5-4

enables

the

operator

to

determine

the

safe

output

of

the

welding

generator

at

various

duty

cycles.

I

IMPORTANT

Exceeding

the

indicated

duty

cycle

will

cause

damage

to

the

internal

components

of

the

welding

generator.

U

250

RATED

OUTPUTi

-~

;;;

-

~bq~

-

-

-

~%

30

40

50

60

70

80

90

100

%

DUTY

CYCLE

B-053

306

Figure

5-4.

Duty

Cycle

Chart

5-

7.

POLARITY

SWITCH

(Optional)

The

POLARITY

SWITCH

provides

a

means

of

selecting

either

DC

STRAIGHT

or

DC

REVERSE

polarity

without

changing

cable

connections.

Do

not

change

the

position

of

the

POLARITY

SWITCH

while

welding

or

under

load,

as

this

causes

arcing

across

the

contacts

of

the

switch.

This

arcing

causes

the

contacts

to

become

pitted

and

eventually

inoperative.

If

the

welding

generator

is

equipped

with

a

POLAR

ITY

SWITCH

(Optional),

the

weld

output

terminals

are

labeled

ELECTRODE

and

WORK.

To

ensure

that

the

weld

current

output

will

be

in

accordance

with

the

labeling

of

the

position

on

the

POLARITY

SWITCH,

connect

the

electrode

holder

cable

to

the

ELEC

TRODE

terminal

and

the

work

cable

to

the

WORK

terminal.

5-

8.

METERS

(Optional)

This

welding

generator

can

be

equipped

with

meters.

The

meters

are

for

monitoring

the

welding

operation

and

serve

as

an

indication

of

the

welding

process.

These

meters

are

internally

connected

to

the

welding

generator

output

ter

minals.

The

voltmeter

will

indicate

the

voltage

at

the

weld

output

terminals,

not

the

actual

voltage

at

the

welding

arc

(due

to

cable

resistance).

The

ammeter

will

indicate

the

current

output

of

the

welding

generator.

5-

9.

240

VOLTS

AC

DUPLEX

RECEPTALCE

(Optional)

(Figure

5-1)

This

welding

generator

is

equipped

with

a

voltage

changeover

terminal

strip

TEl

and

proper

stator

to

provide

reconnection

capbility

for

240

volts

ac.

Although

the

capability

for

either

120

or

240

volts

ac

is

present,

an

optional

kit

must

be

purchased

if

240

volts

is

desired

at

the

front

panel.

A.

Power

Curve

For

Optional

240

VOLTS

AC

Duplex

Receptacle

(See

Figure

5-2).

Up

to

3

kva

of

240

volts

ac

50/60

Hertz

power

is

available

at

the

duplex

receptacle

for

operating

power

tools,

lights,

etc.,

when

the

welding

generator

is

being

operated

at

weld

rpm.

The

FINE

AMPERAGE

control

may

be

in

any

position

when

using

the

240

VOLTS AC

duplex

receptacle

on

the

front

panel.

I.~

The

voltage

will

vary

in

accordance

with

the

load

applied

to

the

240

VOLTS

AC

receptacle.

The

voltage

at

various

loads

may

be

determined

from

Figure

5-2.

B.

Installation

Of 240

VOLTS

AC

Duplex

Receptacle

Ensure

that

the

engine

is

completely

shut

down

before

attempting

any

connections

or

examination

of

com

ponents

on

or

near

terminal

strip

TEl.

TA~

Before

proceeding

with

this

installation,

familiarize

yourself

with

the

circuit

diagram

in

the

Trouble

shooting

Section

of

this

manual.

NOTE

All

directions,

such

as

left

or

right,

are

with

respect

to

1

the

operator

facing

the

welding

generator

front

panel.

U

NOTE

Retain

all

hardware

removed

during

this

procedure

for

i

installation.

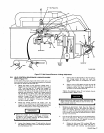

1.

Shut

down

the

welding

generator

and

raise

the

right

I

side

panel.

2.

Remove

center

bolt

from

insulation

board

(see

Figure

5-5),

remove

and

retain

insulation

board.

U

500

~

450

400

4

0

350

z

300

I

I

I

I

I

I

U

Terminal

Strip

TEl.

Duplex

Receptacle

TA-059

485

Figure

5-5.

Location

Of

Reconnectable

Components

tar

Bolt

OM-457

Page

11