SECTION

8

-

GENERATOR

MAINTENANCE

CAUTION__.!

1

If

any

work

is

to

be

done

on

the

rotor

o~enerator,

remove

the

spark

plugs

from

the

engine.

This

will

pre

vent

engine

compression

from

turning

the

rotor

and

catching

the

repairpersons

hand

between

the

rotor

fan

casting

and

the

stationary

adapter

casting.

Also

dis

connect

the

negative

I-)

battery

cable

from

the

battery.

8-1.

GENERAL

Economical

operation

and

trouble-free

service

of

this

weld/

power

generator

are

based

upon

regular

inspections

and

reasonable

attention.

Ottasional

blowing

out

of

the

unit

with

clean

dry

com

pressed

air

is

recommended.

This

should

be

performed

periodically,

depending

upon

the

location

of

the

unit

and

the

amount

of

ckist

and

dirt

in

the

atmosphere.

8-2.

COLLECTOR

RING

BRUSHES

The

brushes

should

be

inspected

periodically

to

ensure

their

proper

function.

The

brush

life

is

very

good

under

normal

conditions.

If

the

generator

has

been

operating

in

an

extremely

dusty

or

dirty

location,

a

close

check

of

the

brushes

for

freedom

of

movement

and

cleanliness

should

be

made

weekly.

Under

normal

use

the

slip

rings

will

discolor

to

a

dark

brown.

If

it

should

become

necessary

to

clean

the

slip

rings,

use

a

3/0

or

finer

sandpaper

followed

by

a

crocus

cloth.

Never

use

emery

cloth

as

part

of

the

emery

will

embed

itself

into

the

rings

and

in

turn

destroy

the

carbon

brushes.

8-3.

WELDING

CABLES

Check

connections

periodically

for

tightness.

The

cables

should

be

inspected

frequently

and

all

brealc

in

the

insula

flon

should

be

repaired

with

electrical

insulating

tape

or

the

cables

replaced.

SECTION

9

-

ENGINE

MAINTENANCE

9-1.

LUBRICATION

This

engine

will

require

at

least

50

hours

of

running

time

to

become

fully

broken

in.

During

this

period,

the

load

on

the

engine

should

be

kept

as

light

as

possible.

The

oil

level

should

be

checked

a

number

of

times

during

an

operating

day,

as

some

engines

will

use

oil

during

the

break-in

period.

After

about

50

hours

of

running

time

on

the

break-in

oil,

drain

the

oil

and

change

the

oil

filter.

Premium

heavy

duty

oil,

manu

factured

by

any

one

of

the

major

oil

companies,

should

be

used

as

a

replacement

oil.

Table

9-1

gives

a

list

of

recom

mended

grades

and

types

of

oil

to

use

to

keep

oil

level

up

during

break-in

and

to

use

after

the

break-in

oil

is

drained.

The

capacity

of

the

engine

with

a

filter

change

is

4-1/2

quarts,

without

a

filter

change.

4

quarts.

Check

the

dip

stick

to

make

sure

oil

level

is

up

to

the

required

operating

level.

9-2.

COOLANT

SYSTEM

Caution

should

be

exercised

at

all

times

when

remov

ing

the

radiator

pressure

cap.

The

cap

will

turn

to

an

almost

full

open

position,

at

which

point

a

provision

has

been

made

to

permit

venting

built

up

pressure

within

the

radiator.

Allow

the

pressure

to

escape

before

completely

removing

the

cap

from

the

radiator

neck.

When

removing

the

cap,

it

is

recommended

that

a

glove

or

rag

be

used

to

protect

the

operators

hand

from

possible

exposure

to

extremely

hot

coolant.

~mixd4erenandso!ls.GeneraIly,motor

oils

fall

into

two

categories:

phosphate

base,

and

sulphonate

base.

The

phosphate

base

oils

are

acidic;

the

sulphonates

are

alkaline.

Although

both

bases

produce

good

oils,

mixing

the

two

bases

produces

a

chemical

reaction

which

greatly

reduces

the

lubri

cating

properties

of

either

oil.

The

mixing

of

oils

could

~cause

extensive

damage

to

the

engine.

1

If

the

engine

is

to

be

operated

in

a

temperature

below

0F,

make

sure

a

good

grade

of

ethylene

glycol

anti-freeze

is

added

to

the

coolant

system.

Change

the

coolant

solution

as

often

as

necessary.

The

coolant

system

capacity

is

9

quarts

lU.S.

Measure).

During

the

break-in

period

of

a

new

engine,

one

of

the

great

est

dangers

is

over-heating.

There

are

several

possible

causes

of

over-heating,

but

the

basic

items

for

consideration

are

engine

lubrication

and

coolant

circulation.

At

the

first

sign

of

over-heating,

shut

the

engine

down

and

make

a

thorough

check

to

determine

the

cause.

In

normal

operation,

oil

should

be

changed

after

about

50

hours

of

operation

with

a

filter

change

every

150

hours.

The

oil

should

be

drained

after

the

engine

has

been

warmed

up

to

normal

operating

temperature,

thus

promoting

foreign

par

ticle

suspension

in

the

oil

and

thereby

removal

when

the

oil

is

drained.

Foreign

particles

tend

to

settle

at

the

bottom

of

the

crankcase

when

the

oil

is

allowed

to

cool,

thereby

avoiding

removal

and

thus

contaminating

the

new

oil

added.

Temperature

of

the

engine

coolant

is

regulated

by

a

thermo

static

valve

located

in

the

outlet

at

the

front

of

the

cylinder

head.

This

unit

retards

the

flow

oL

coolant

until

a

pre

determined

tem~erature

is

reached,

usually

varying

between

170F

and

180

F.

When

the

desired

temperature

is

achieved,

the

valve

opens

and

free

circulation

of

the

coolant

through

the

system

begins.

1

th~

tliermostal

uiuud

fail,

replace

it

immediately.

Ensure

that

the

replacement

has

an

equal

temperature

rating.

Do

not

run

the

engine

without

a

thermostat.

If

the

thermostat

remains

closed,

the

engine

will

over

heat.

If

the

thermostat

remains

open,

or

the

engine

is

run

without

a

thermostat,

the

engine

will

run

cold.

As

a

result,

excess

carbon

will

accumulate

and

the

oil

will

become

contaiminated

with

sludge.

flTAr~

The

engine

fan

and

alternator

belts

are

subject

to

nor

mal

wear

and

should

be

checked

for

proper

tension

periodically.

Check

and

readjust

tension

after

the

first

50

hours

of

operation,

and

whenever

belts

are

re

placed.

CAUTION

N

U

I

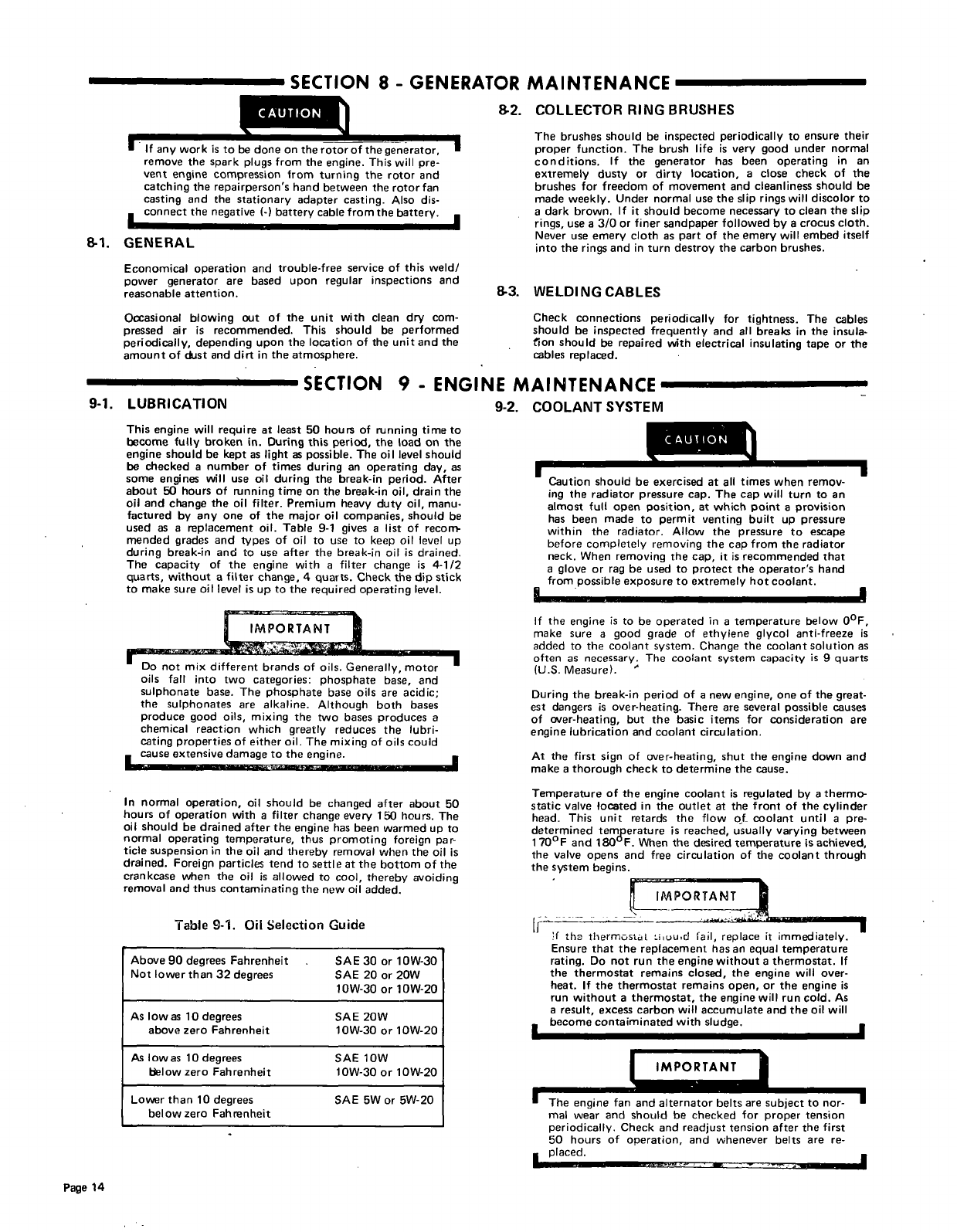

Table

9-1.

Oil

Selection

Guide

Above

90

degrees

Fahrenheit

.

SAE3O

or

10W-30

Not

lower

than

32

degrees

SAE

20

or

20W

1OW-30

or

1OW-20

As

low

as

10

degrees

SAE

20W

above

zero

Fahrenheit

1OW-30

or

1OW-20

Aslowas

lOdegrees

SAE

lOW

slow

zero

Fahrenheit

1OW-30

or

1OW-20

Lower

than

10

degrees

SAE

SW

or

5W-20

below

zero

Fahrenheit

I

Page

14