CAUTION.:

-

Add

CAUTION

block

at

beginning

of

Section

/

The

weld

output

terminals

are

electrically

energized

when

the

engine

is

running.

Disconnect

the~

we/ding

cables

when

not

we/ding

and

do

not

touch

the

output

terminals

when

the

engine

is

running.

AMENDMENT

TO

SECTION

9-

ENGINE

MAINTENANCE

Amend

Section

9-3.

GOVERNOR

SERVICE

Weld

speed

of

this

engine

is

1850

rpm.

Amend

Section

9-4.

CARBURETOR

FLOAT

SETTING

Carburetor

Change

Effective

With

Serial

No.

HJ185451

I~1t~

Do

not

bend,

twist,

or

apply

pressure

on

the

float

body.

The

float

body,

when

viewed from

the

free

end,

must

be

centered

between

and

at

right

angles

to

the

machined

surface,

and

must

move

freely

on

the

float

axle.

This

engine

is

equipped

with

a

Teledyne

Walbro

carburetor.

To

ensure

correct

fuel

level

in

the

float

chamber,

check

distance

(dimension

A,

Figure

9-1)

from

top

of

float

to

machined

surface

of

throttle

body

(no

gasket)

with

throttle

body

inverted.

This

dimension

should

be

1-1/16

inches

plus

or

minus

.020

inch.

To

increase

or

decrease

distance

from

the

top

of

the

float

body

to

the

machined

surface,

use

a

long

nose

pliers

and

bend

the

float

lever

at

a

point

close

to

the

float

body.

Delete

Figure

9-2.

Carburetor

Float

Setting

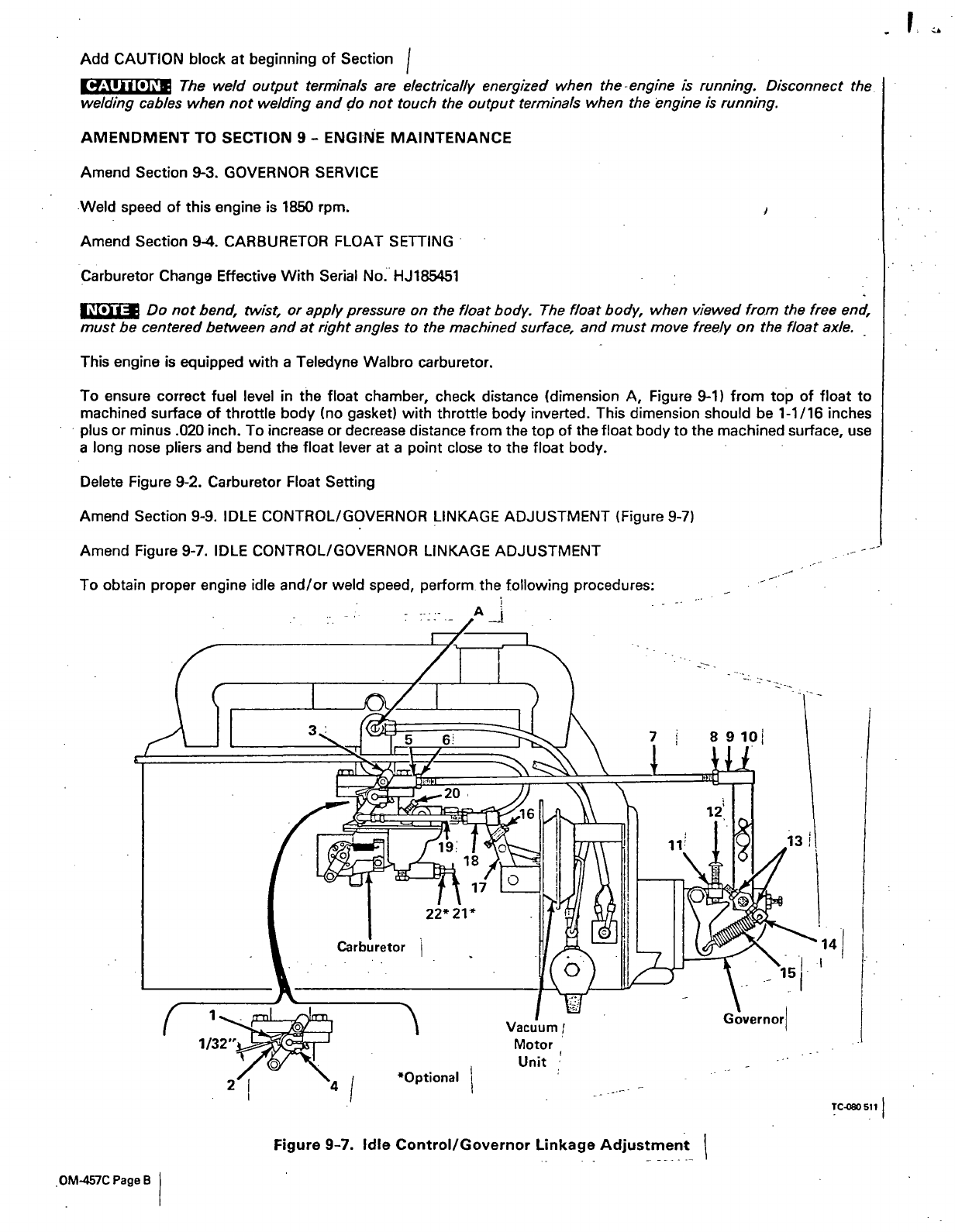

Amend

Section

9-9.

IDLE

CONTROL/GOVERNOR

LINKAGE

ADJUSTMENT

(Figure

9-7)

Amend

Figure

9-7.

IDLE

CONTROL/GOVERNOR

LINKAGE

ADJUSTMENT

To

obtain

proper

engine

idle

and/or

weld

speed,

perform~

the

following

procedures:

0M-457C

Page

B

Figure

9-7.

Idle

Control/Governor

Linkage

Adjustment

TCO8O

511