9-3.

GOVERNOR

SERVICE

The

governor

speed

setting

and

sensitivity

setting

are

factory

set

to

obtain

Correct

weld

rpm

and

engine

response

to

chang

ing

load

conditions.

The

governor

speed

control

setting

is

factory

locked

with

a

lead

seal.

Do

not

remove

this

seal

un

less

absolutely

necessary.

NOTE

The

governor,

as

used

in

conjunction

with

this

engine,

does

not

have

a

No

Load

Surge

adjustment

as

,d~cribed

in

the

Engine

Manual.

The

engine

is

factory

set

to

operate

at

1200

rpm

idle

speed

and

1800

rpm

when

it

comes

up

to

weld

speed.

For

infornia

tion

concerning

governor

adjustment,

refer

to

the

Engine

Manual,

Page

41,

paragraph

entitled

Pierce

Governor.

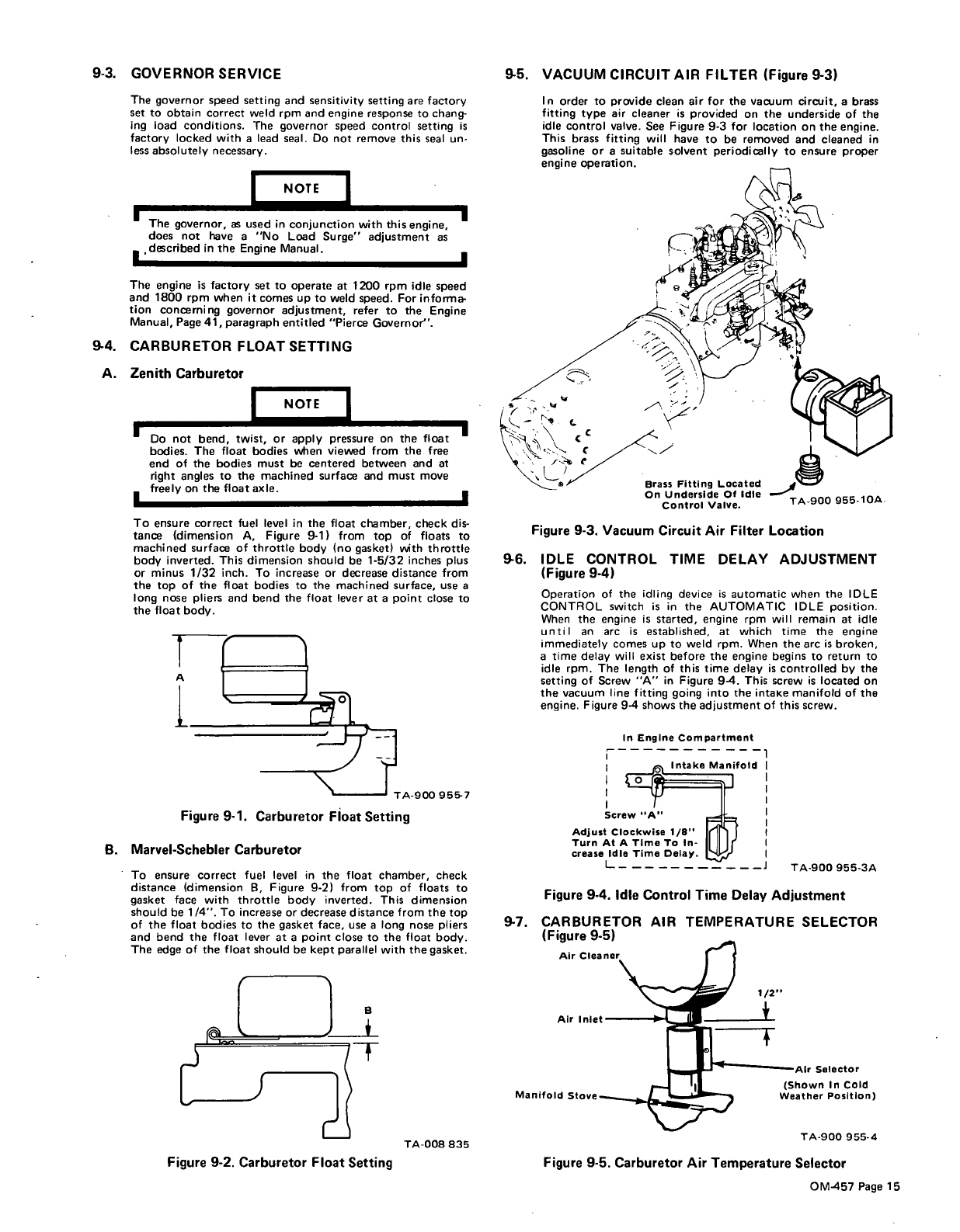

9-4.

CARBURETOR

FLOAT

SETTING

A.

Zenith

Carburetor

NOTE

Do

not

bend,

twist,

or

apply

pressure

on

the

float

bodies.

The

float

bodies

when

viewed

from

the

free

end

of

the

bodies

must

be

centered

between

and

at

right

angles

to

the

machined

surface

and

must

move

freely

on

the

float axle.

To

ensure

correct

fuel

level

in

the

float

chamber,

check

dis

tance

(dimension

A,

Figure

9-1)

from

top

of

floats

to

machined

surface

of

throttle

body

(no

gasket)

with

throttle

body

inverted.

This

dimension

should

be

1-5/32

inches

plus

or

minus

1/32

inch.

To

increase

or

decrease

distance

from

the

top

of

the

float

bodies

to

the

machined

surface,

use

a

long

nose

pliers

and

bend

the

float

lever

at

a

point

close

to

the

float

body.

B.

Marvel-Schebler

Carburetor

To

ensure

correct

fuel

level

in

the

float

chamber,

check

distance

(dimension

B,

Figure

9-2)

from

top

of

floats

to

gasket

face

with

throttle

body

inverted.

This

dimension

should be

1/4.

To

increase

or

decrease

distance

from

the

top

of

the

float

bodies

to

the

gasket

face,

use

a

long

nose

pliers

and

bend

the

float

lever

at

a

point

close

to

the

float

body.

The

edge

of

the

float

should

be

kept

parallel

with

the

gasket.

9-5.

VACUUM

CIRCUIT

AIR

FILTER

(Figure

9-3)

In

order

to

provide

clean

air

for

the

vacuum

circuit,

a

brass

fitting

type

air

cleaner

is

provided

on

the

underside

of

the

idle

control

valve.

See

Figure

9-3

for

location

on

the

engine.

This

brass

fitting

will

have

to

be

removed

and

cleaned

in

gasoline

or

a

suitable

solvent

periodicelly

to

ensure

proper

engine

operation.

Figure

9-3.

Vacuum

Circuit

Air

Filter

Location

9-6.

IDLE

CONTROL

TIME

DELAY

ADJUSTMENT

(Figure

9-4)

Operation

of

the

idling

device

is

automatic

when

the

IDLE

CONTROL

switch

is

in

the

AUTOMATIC

IDLE

position.

When

the

engine

is

started,

engine

rpm

will

remain

at

idle

until

an

arc

is

established,

at

which

time

the

engine

immediately

comes

up

to

weld

rpm.

When

the

arc

is

broken,

a

time

delay

will

exist

before

the

engine

begins

to

return

to

idle

rpm.

The

length

of

this

time

delay

is

controlled

by

the

setting

of

Screw

A

in

Figure

9-4.

This

screw

is

located

on

the

vacuum

line

fitting

going

into

the

intake

manifold

of

the

engine.

Figure

9-4

shows

the

adjustment

of

this

screw.

In

Engine

Compartment

d

Screw

A

Adjust

Clockwise

1/8

Turn

At

A

Time

To

In-

crease

Idle

Time

Delay.

~

L..

__j

Brass

Fitting

Located

On

Underside

Of

Idle

Control

Valve.

TA-900

955-bA

TA-900

955-7

Figure

9-1.

Carburetor

Float

Setting

TA-gOD

955-3A

Figure

9-4.

Idle

Control

Time

Delay

Adjustment

9-7.

CARBURETOR

AIR

TEMPERATURE

SELECTOR

(Figure

9-5)

Air

Cleaner

Air

Inlet

Selector

(Shown

In

Coid

Manifoid

Stove

Weather

Position)

TA-900

955-4

Figure

9-5.

Carburetor

Air

Temperature

Selector

Figure

9-2.

Carburetor

Float

Setting

TA-008

835

OM-457

Page

15