SECTION

5-FUNCTION

OF

GENERATOR

CONTROLS

The

contacts

of

the

FINE

AMPERAGE

control

are

of

the

continuous

contact

type,

thereby

making

it

possible

to

fine

adjust

the

amperage

output

while

i

welding

The

scale

surrounding

the

FINE

AMPERAGE

control

is

calibrated

from

0

to

100

percent

in

increments

of

ten.

Due

to

this

percentage

calibration,

it

should

be

noted

that

if

the

operator

is

using

this

scale

to

select

a

fine

amperage

setting,

the

operator

is

selecting

a

percentage

of

the

coarse

range

in

use

and

not

an

actual

amperage

value.

I

The

FINE

AMPERAGE

control

must

be

rotated

to

the

100

(full

counterclockwise)

position

whenever

the

120/240

volts

power

plant

is

being

utilized.

The

FINE

AMPERAGE

control

may

be

in

any

position

when

using

the

120

VOLTS

AC

duplex

receptacle

on

the

front

panel.

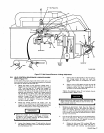

Fi~jre

5-1.

Generator

Controls

TB-004

284

5.

1.

120

VOLTS

AC

RECEPTACLE

(Figure

5-1)

(For

Optional

240

Volts

AC

Receptacle,

See

Section

5-9)

Up

to

3

kva

of

120

volts

ac

50/60

Hertz

power

is

available

at

this

duplex

receptacle

for

operating

120

volts

ac or

120

volts

universal

power

tools

etc.,

when

the

welding

generator

is

being

operated

at

weld

rpm.

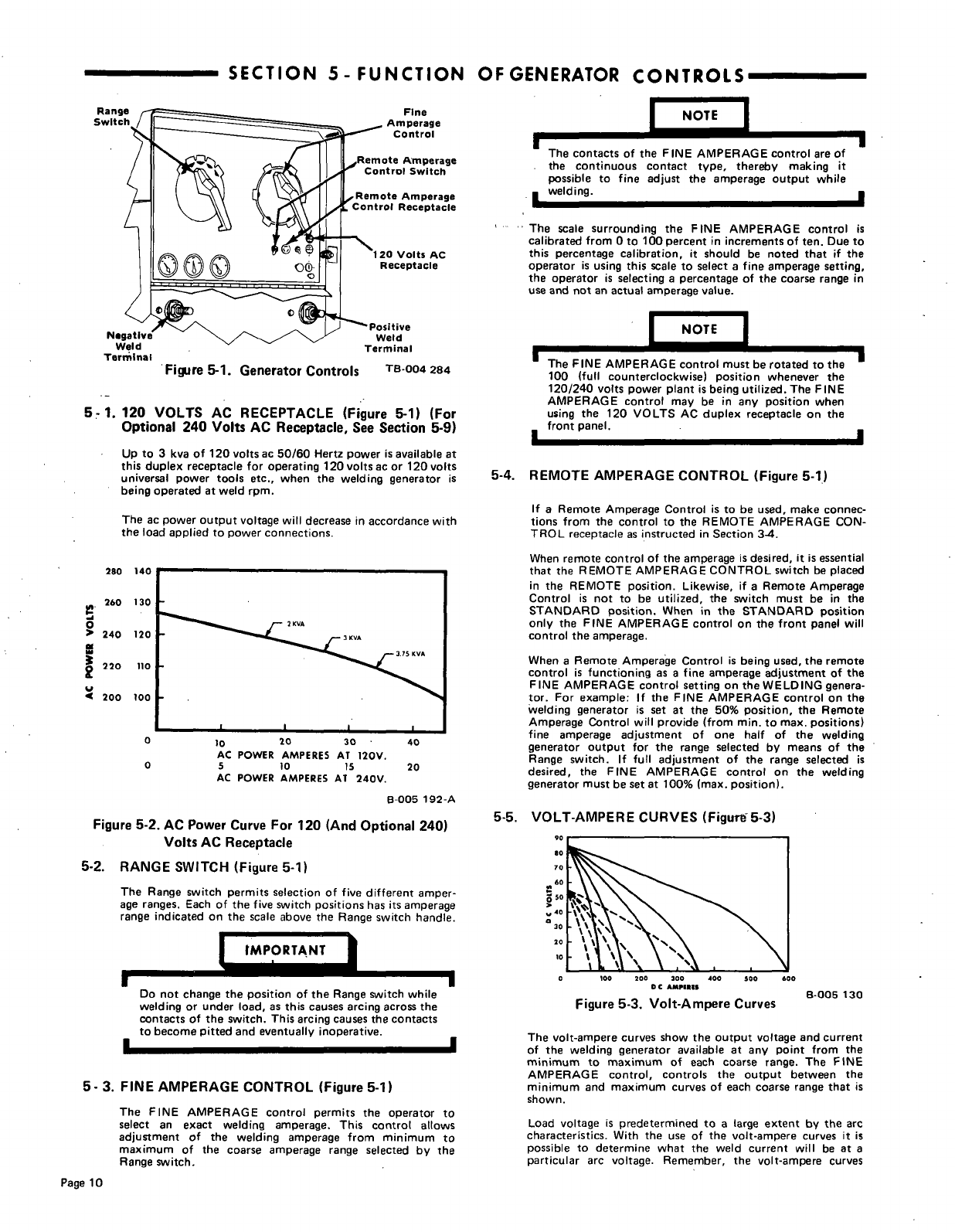

The

ac

power

output

voltage

will

decrease

in

accordance

with

the

load

applied

to

power

connections.

280

140

I

U

260

130

>

240

120

220

110

~

200

100

0

0

20

30

40

AC

POWER

AMPERES

AT

120V.

5

10

15

20

AC

POWER

AMPERES

AT

240V.

B-005

192-A

Figure

5-2.

AC

Power

Curve

For

120

(And

Optional

240)

Volts

AC

Receptacle

5-2.

RANGE

SWITCH

(Figure

5-1)

The

Range

switch

permits

selection

of

five

different

amper

age

ranges.

Each

of

the

five

switch

positions

has

its

amperage

range

indicated

on

the

scale

above

the

Range

switch

handle.

5-4.

REMOTE

AMPERAGE

CONTROL

(Figure

5-1)

If

a

Remote

Amperage

Control

is

to

be

used,

make

connec

tions

from

the

control

to

the

REMOTE

AMPERAGE

CON

TROL

receptacle

as

instructed

in

Section

3-4.

When

remote

control

of

the

amperage

is

desired,

it

is

essential

that

the

REMOTE

AMPERAGE

CONTROL

switch

be

placed

in

the

REMOTE

position.

Likewise,

if

a

Remote

Amperage

Control

is

not

to

be

utilized,

the

switch

must

be

in

the

STANDARD

position.

When

in

the

STANDARD

position

only

the

FINE

AMPERAGE

control

on

the

front

panel

will

control

the

amperage.

When

a

Remote

Amperage

Control

is

being

used,

the

remote

control

is

functioning

as

a

fine

amperage

adjustment

of

the

FINE

AMPERAGE

control

setting

on

the

WELDING

genera

tor.

For

example:

If

the

FINE

AMPERAGE

control

on

the

welding

generator

is

set

at

the

50%

position,

the

Remote

Amperage

Control

will

provide

(from

mm.

to

max.

positions)

fine

amperage

adjustment

of

one

half

of

the

welding

generator

output

for

the

range

selected

by

means

of

the

Range

switch.

If

full

adjustment

of

the

range

selected

is

desired,

the

FINE

AMPERAGE

control

on

the

welding

generator

must

be

set

at

100%

(max.

position).

5-5.

VOLT-AMPERE

CURVES

(Figur~5-3)

0

100

200 300

400

300 600

DC

AMPIIIS

Figure

5-3.

Volt-Ampere

Curves

B-005

130

The

volt-ampere

curves

show

the

output

voltage

and

current

of

the

welding

generator

available

at

any

point

from

the

minimum

to

maximum

of

each

coarse

range.

The

FINE

AMPERAGE

control,

controls

the

output

between

the

minimum

and

maximum

curves

of

each

coarse

range

that

is

shown.

Load

voltage

is

predetermined

to

a

large

extent

by

the

arc

characteristics.

With

the

use

of

the

volt-ampere

curves

it

is

possible

to

determine

what

the

weld

current

will

be

at

a

particular

arc

voltage.

Remember,

the

volt-ampere

curves

tMPORTANT

I

U

Do

not

change

the

position

of

the

Range

switch

while

welding

or

under

load,

as

this

causes

arcing

across

the

contacts

of

the

switch.

This

arcing

causes

the

contacts

to

become

pitted

and

eventually

inoperative.

U

I

5-

3.

FINE

AMPERAGE

CONTROL

(Figure

5-1)

The

FINE

AMPERAGE

control

permits

the

operator

to

select

an

exact

welding

amperage.

This

control

allows

adjustment

of

the

welding

amperage

from

minimum

to

maximum

of the

coarse

amperage

range

selected

by

the

Range

switch.

Page

10