tMPORTANT

Replace

the

spark

arrestor

if

inspection

reveals

any

signs

of

failure.

I

The

engine

exhaust

system

on

this

welding

generator

has

not

been

equipped

with

a

spark

arrestor

unless

it

was

specifically

ordered

as

an

optional

accessory.

A

spark

arrestor,

maintained

in

effective

working

order,

is

mandatory

if

this

welding

generator

is

to

be

operated

in

a

National

Forest,

or

on

California

grasslands,

brush,

or

forest

covered

land

(see

Section

4442

of

California

Public

Resources

Code).

For

other

areas,

check

your

state

and

local

laws.

A.

Inspection

1.

Visually

examine

the

outside

of

the

device

for

holes,

cracks,

or

metal

corrosion.

2.

With

the

engine

stopped,

look

inside

the

spark

arrestor

outlet

tube with

a

flashlight

or

other

light

source.

Visually

examine

the

vanes

and

the

outlet

tube

for

metal

or

weld

failure.

The

vanes

must

be

firmly

attached

to

the

inlet

tube

and

the

outlet

tube

must

be

completely

intact

(this

is

an

important

factor

in

maintaining

spark

arresting

efficiency).

3.

Check

the

mounting

clamp

to

ensure

that

the

spark

arrestor

is

securely

mounted.

1.

Stop

the

engine

and

allow

the

exhaust

system

to

cool.

2.

Remove

the

cleanout

plug

from

the

bottom

of

the

spark

arrestor

with

a

wrench.

If

a

crust

has

formed

over

the

hole,

break

it

loose

with

a

screwdriver

or

similar

tool.

3.

Start

the

engine

and

run

it

at

idle

rpm

to

blow

collected

particles

out

the

cleanout

hole.

If

particles

are

slow

to

discharge,

momentarily

cover

the

end

of

the

exhaust

stack.

4.

Stop

the

engine.

Replace

and

secure

the

cleanout

plug.

TC-003

226

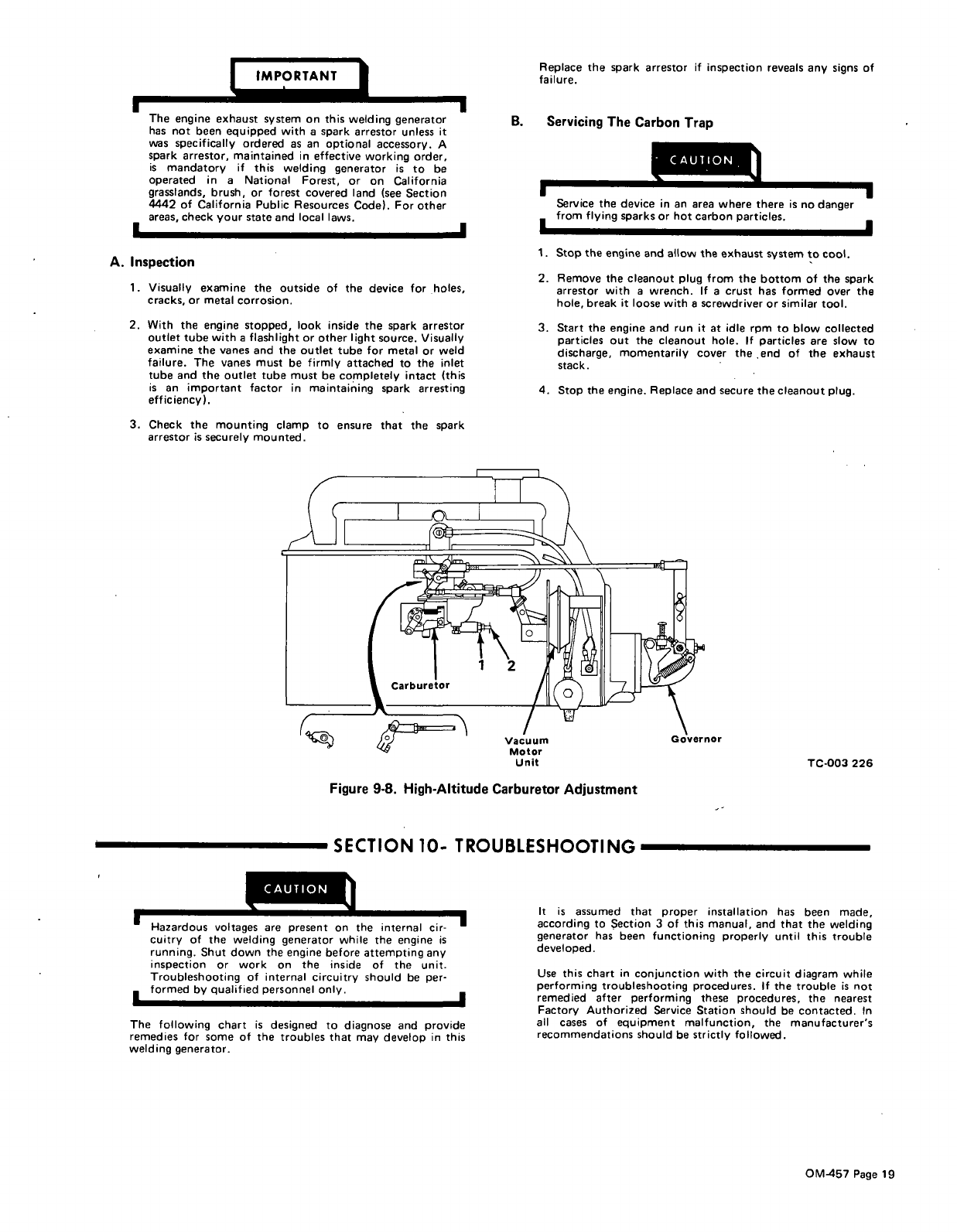

Figure

9-8.

High-Altitude

Carburetor

Adjustment

SECTION

10-

TROUBLESHOOTING

CAUTION

Hazardous

voltages

are

present

on

t~ternalcir

cuitry

of

the

welding

generator

while

the

engine

is

running.

Shut

down

the

engine

before

attempting

any

inspection

or

work

on

the

inside

of

the

unit.

Troubleshooting

of

internal

circuitry

should

be

per

formed

by

qualified

personnel

only.

It

is

assumed

that

proper

installation

has

been

made,

according

to

Section

3

of

this

manual,

and

that

the

welding

generator

has

been

functioning

properly

until

this

trouble

developed.

Use

this

chart

in

conjunction

with

the

circuit

diagram

while

performing

troubleshooting

procedures.

If

the

trouble

is

not

remedied

after

performing

these

procedures,

the

nearest

Factory

Authorized

Service

Station

should

be contacted.

In

all

cases

of

equipment

malfunction,

the

manufacturers

recommendations

should

be

strictly

followed.

I

B.

Servicing

The

Carbon

Trap

I

I

I

I

Service

the

device

in

an

area

where

there

is

no

danger

from

flying

sparks

or

hot

carbon

particles.

Vacuum

Motor

Unit

The

following

chart

is

designed

to

diagnose

and

provide

remedies

for

some

of

the

troubles

that

may

develop

in

this

welding

generator.

OM-457

Page

ig