INSTALLATION AND WIRING

13

9) When rewiring after operation, make sure that the POWER lamp has gone off, and when more than 10

minutes have elapsed after power-off, check with a meter that the voltage is zero. After that, start rewiring

work. For some time after power-off, there is a dangerous voltage in the capacitor.

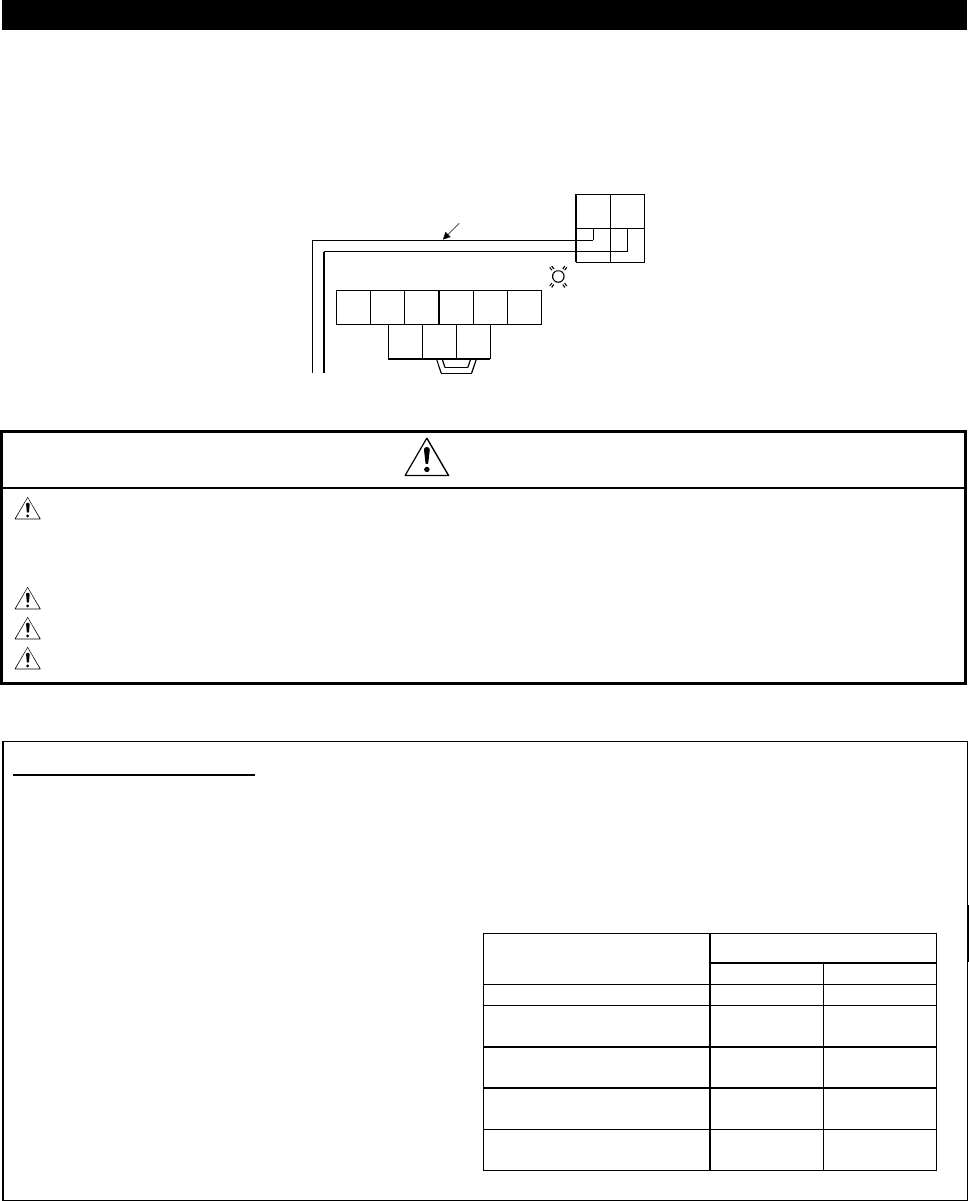

10) Use the space on the left-hand side of the main circuit terminal block to wire the cables for connection of

the power supply terminals R1, S1 for the control circuit of the FR-F520-11K.

UVW

P1

Screw size (M5)

Connection cable

Charge lamp

T

NP

R1 S1

RS

CAUTION

Do not use residual current protective device as the only protection against indirect

contact.

Protective earth connection essential.

Do not connect more than 2 wires on the protective earth terminal.

Use contactor and no fuse breaker EN/IEC standard compliant.

Use transformer or surge absorber EN/IEC standard compliant.

Notes on Grounding

•

Leakage currents flow in the inverter. To prevent an electric shock, the inverter and motor must be

grounded.

•

Use the dedicated ground terminal to ground the inverter. (Do not use the screw in the case, chassis,

etc.)

(Unit: mm

2

)

Ground Cable Gauge

Motor Capacity

200V class 400V class

3.7 kW (5 HP) or less 3.5 2

5.5 kW, 7.5 kW

(7.5 HP, 10 HP)

5.5 3.5

11 kW to 15 kW

(15 to 20 HP)

14 8

18.5 kW to 37 kW

(25 to 50 HP)

22 14

45 kW, 55 kW

(60 HP, 75 HP)

38 22

•

The ground cable should be as thick as possible.

Its gauge should be equal to or larger than those

indicated in the following table. The grounding

point should be as near as possible to the inverter

to minimize the ground cable length.

•

Ground the motor on the inverter side using one

wire of the 4-core cable.