3.3 Parameter Checking and Setting

OPERATION/CONTROL

52

3.3 Parameter Checking and Setting

The inverter is designed to perform simple variable-speed operation with the factory settings of the

parameters. Set the necessary parameters according to the load and operation specifications. Use the

operation panel (FR-DU04) to set, charge and confirm the parameter values. For full information on the

parameters, refer to “CHAPTER 4 PARAMETERS”(Page 60).

3.3.1 Parameter checking

Pr. 160 "user group read selection" is factory-set to display only the simple mode parameters among the

parameters. Set the following parameters as required.

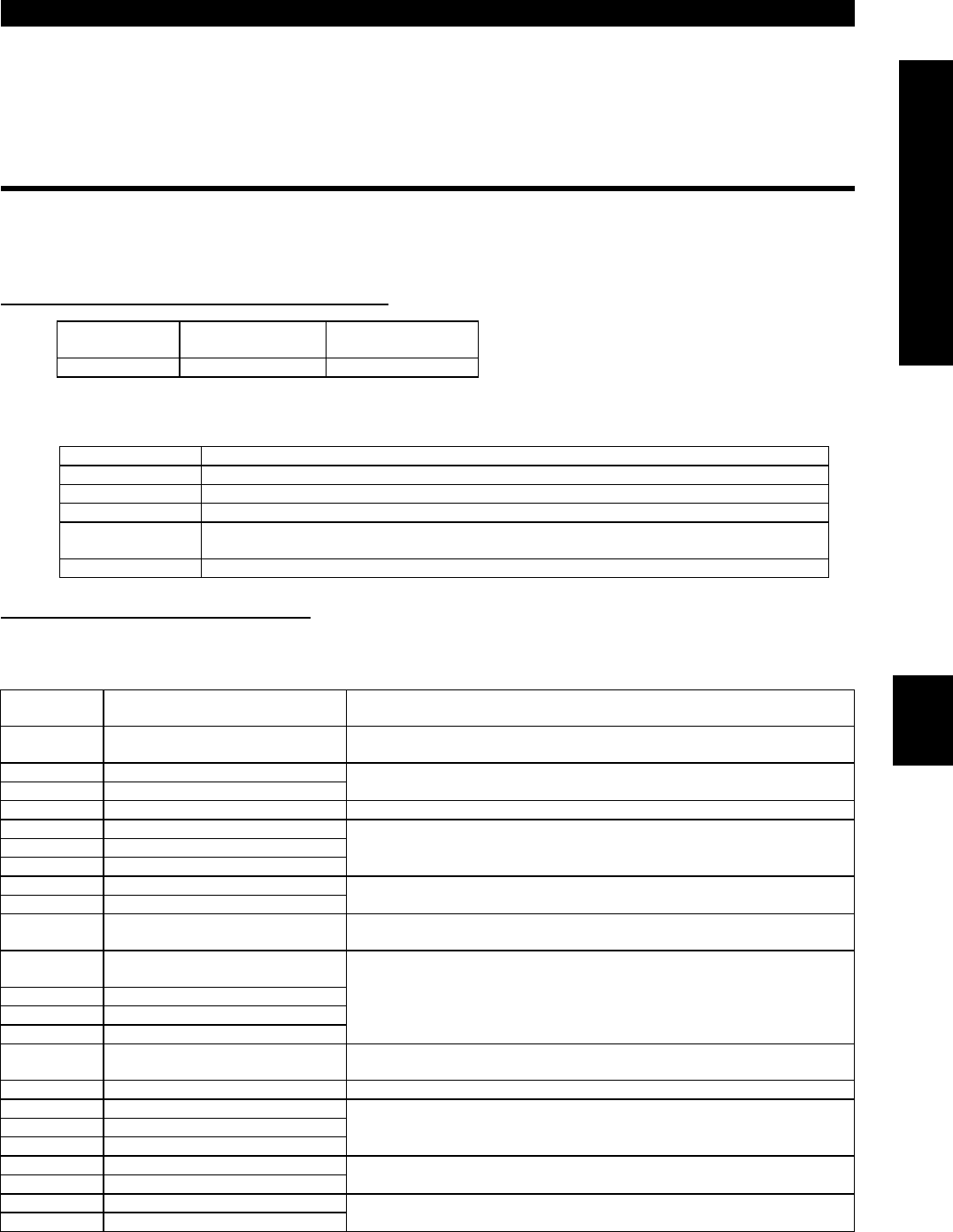

(1) Pr. 160 "user group read selection"

Parameter

Number

Factory Setting Setting Range

160 9999 0, 1, 10, 11, 9999

•

Setting details

For the setting method and in-depth explanation, refer to page 137.

Pr. 160 Setting Description

0 All parameters are made accessible for reading and writing.

1 Only the parameters registered in user group 1 are made accessible for reading and writing.

10 Only the parameters registered in user group 2 are made accessible for reading and writing.

11

Only the parameters registered in user groups 1 and 2 are made accessible for reading and

writing.

9999 Only the simple mode parameters are made accessible for reading and writing. (Factory setting)

(

2

)

Simple mode parameter list

The following parameters are basic parameters made accessible for reading and writing by setting "9999" in

Pr. 160. For details of their functions, refer to Chapter 4 "PARAMETERS" (page 60).

Parameter

Number

Name Application

0 Torque boost

Used to compensate for a voltage drop in the low frequency range to improve

motor torque reduction in the low speed range.

1 Maximum frequency

2 Minimum frequency

Used to set the upper and lower limits of the output frequency.

3 Base frequency Used to match the inverter outputs (voltage, frequency) to the motor rating.

4 Three-speed setting (high speed)

5 Three-speed setting (middle speed)

6 Three-speed setting (low speed)

Set these parameters when using the terminals to change the running speeds

preset in the parameters.

7 Acceleration time

8 Deceleration time

Used to set the acceleration and deceleration times.

9 Electronic thermal O/L relay

Used to set the current value of the electronic overcurrent protection to protect the

motor from overheat.

10

DC injection brake operation

frequency

11 DC injection brake operation time

12 DC injection brake voltage

13 Starting frequency

Used to adjust the stopping accuracy according to the load.

14 Load pattern selection

Used to select the optimum output characteristic that matches the application and

load characteristics.

19 Base frequency voltage Used to set the base voltage (e.g. motor's rated voltage).

52 DU/PU main display data selection

53 PU level display data selection

54 FM terminal function selection

Used to choose the monitoring and output signals.

55 Frequency monitoring reference

56 Current monitoring reference

Used to set the frequency and current values, which are referenced, for the level

meter.

57 Restart coasting time

58 Restart cushion time

Used to perform automatic restart operation after instantaneous power failure or

commercial power supply-inverter switchover.

3

Simple mode parameter