-18-

Model G0763 (Mfg. Since 8/13)

Assembly

For accurate results and to prevent warping

the cast iron ways, the table MUST be level

from side to side and from front to back.

Recheck the ways 24 hours after installation,

two weeks after that, and then annually to

make sure they remain level.

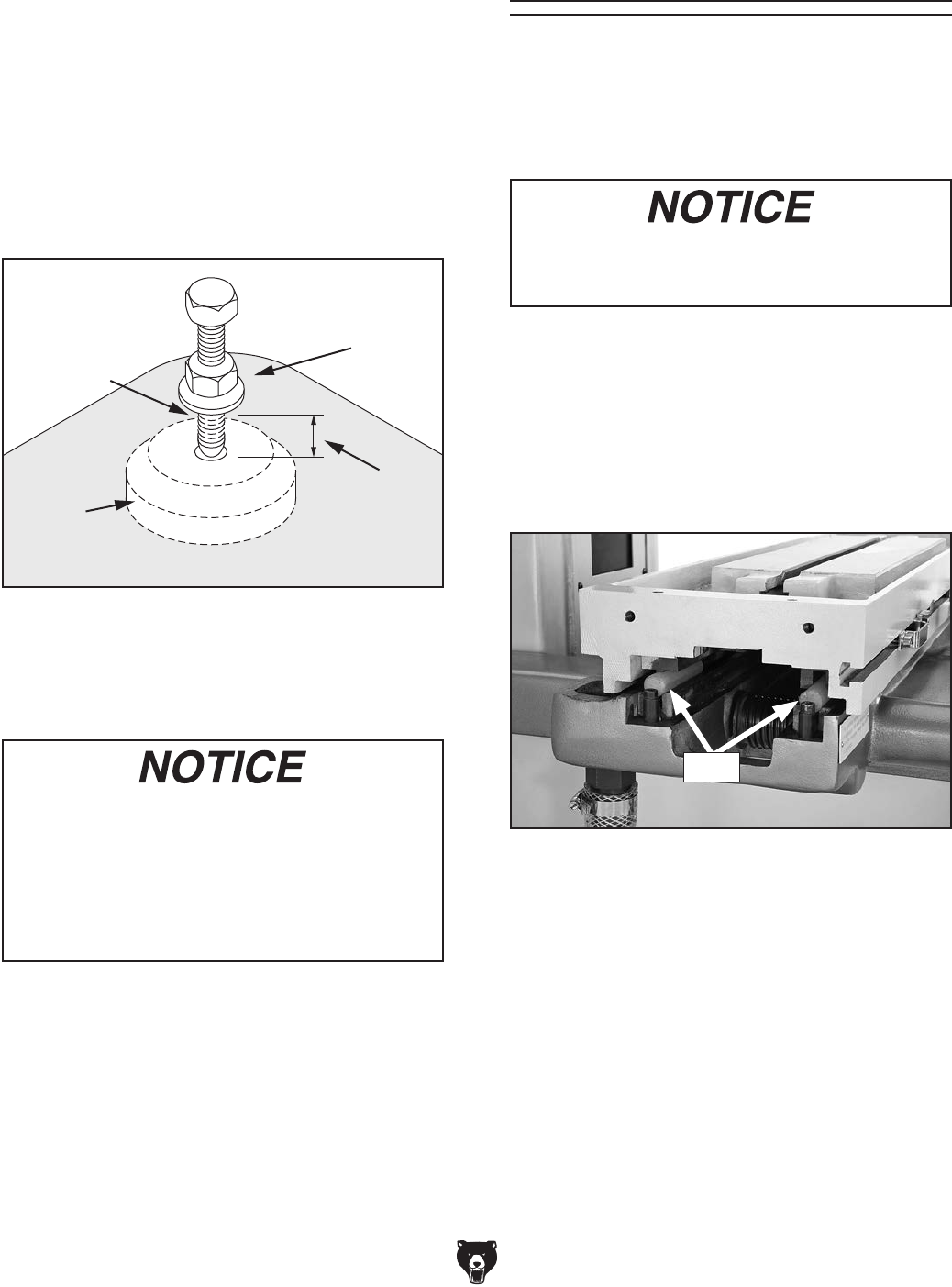

10. With help from another person to steady the

load, lift machine enough to remove pallet.

11. With machine still suspended above floor,

thread leveling pad bolts, as illustrated in

Figure 14, into holes used to bolt machine to

pallet.

Note: Make sure flat washer and hex nut

are above machine base and bottom of bolt

extends approximately

3

⁄4" below machine

base.

Leveling

Pad

Threaded

Hole

Flat Washer

& Nut Above

Machine Base

Approx.

3

⁄4"

Figure 14. Leveling pad and bolt installed.

13. Using a precision level on unpainted table

surface without magnetic chuck, adjust level-

ing pad bolts until table is level from side to

side and front to back.

14. When table is properly leveled, tighten down

hex nuts on bolts to secure settings.

15. Reconnect coolant pump electrical cord and

coolant hose.

To assemble the surface grinder:

1. Install handles on X- and Z-axis handwheels.

2. Remove table restraints.

Take care not to damage table or saddle

ways. Any damage to these surfaces will be

permanent and result in poor finishes.

3. With help from another person, remove table

and place it upside down on a clean, flat sur-

face.

4. Store plastic shipping rods (see Figure 15) for

future use when storing or moving machine to

protect ways.

5. Clean the table and saddle ways, and

table ball bearing segments, as directed on

Page 15.

12. Position leveling pads underneath bolts and

lower machine so the bolts rest in center of

pads.

Figure 15. Plastic rods used for shipping or

storage purposes.

Rods