-26-

Model G0763 (Mfg. Since 8/13)

Wheel Inspection

Do not assume that a wheel is in sound condition

just because it is new—damage can often occur

during shipping, with age, with prolonged expo-

sure to moisture, or because of improper storage.

To inspect a wheel for damage:

1. Remove wheel flange and sleeve, then look

for any cracks, chips, nicks, or dents in wheel

surface. If you see any of these, DO NOT

attempt to use wheel.

2. Do a ring test. This test will give you an indi-

cation of any internal damage that may not be

obvious during a visual inspection.

3. Inspect paper washers on both sides of grind-

ing wheel (see Figure 28).

These washers are cushions between wheel

sleeve and flange and grinding wheel. Without

paper washers, cracks can be spawned from

center of wheel when the arbor nut is tight-

ened. Over time, these cracks can radiate

outward and the wheel may explode during

operation, possibly causing injury.

Figure 28. Important wheel paper washer.

Paper Washer

Note: If you need to replace or install new

paper washers, replacements can be cut out

of any thick construction paper or card stock.

Regular notebook paper or paper from a copy

machine is not acceptable, as it is too thin to

provide required cushion. Be sure to transfer

any RPM limitations and wheel type informa-

tion to the new paper washers.

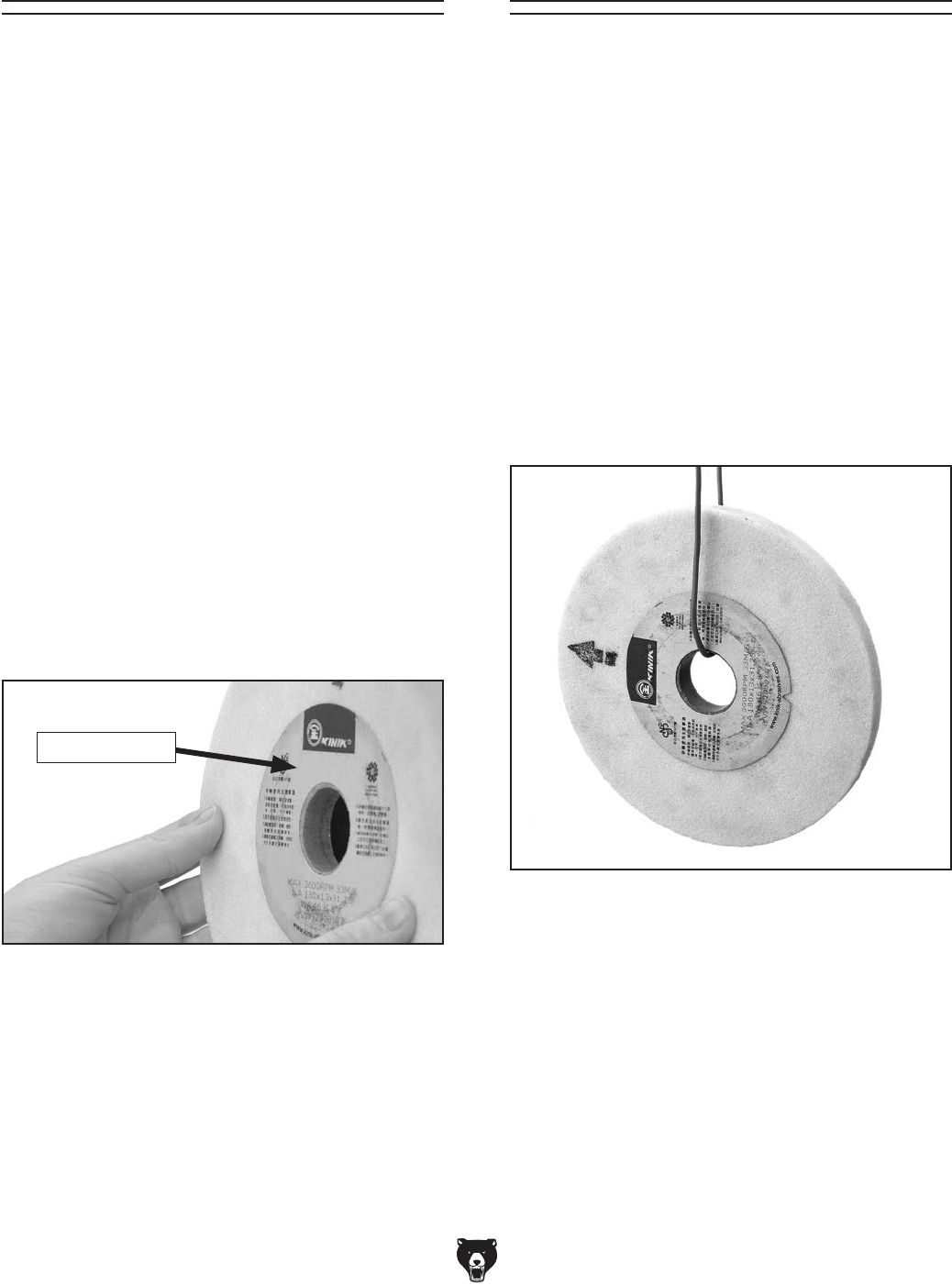

R i n g Te s t

This test will give you an indication of any internal

damage that may not be obvious during a visual

inspection.

To perform a ring test:

1. Make sure wheel that you test is clean and

dry; otherwise, you may get false results.

Note: If wheel is wet with coolant, hang it in a

dry location until it is dry (usually overnight).

2. Remove wheel flange and sleeve.

3. Hang wheel in air with a piece of cord or

string looped through wheel bore, as shown

in Figure 29.

4. At locations shown with an X in Figure 29,

gently tap wheel with a light non-metallic

device such as handle of a screwdriver or a

wooden mallet.

An undamaged wheel will emit a clear metal-

lic ring or “ping” sound in each of these spots.

A damaged wheel will respond with a dull

thud that has no clear tone. If you determine

from ring test that wheel is damaged, DO

NOT use it!

x

x

Figure 29. Ring test setup.

x

x

x

x