Model G0763 (Mfg. Since 8/13)

-25-

Most grinding wheels from major manufactur-

ers are marked in a somewhat uniform man-

ner. Understanding these markings will help you

understand the capabilities of various wheels.

Always refer to the manufacturer’s grinding rec-

ommendations when selecting a wheel for your

project.

The grinding wheel you choose will depend on

several factors related to the operation you plan to

perform. The hardness of the material you will be

grinding and the surface finish you desire are the

two primary factors to consider when selecting a

grinding wheel.

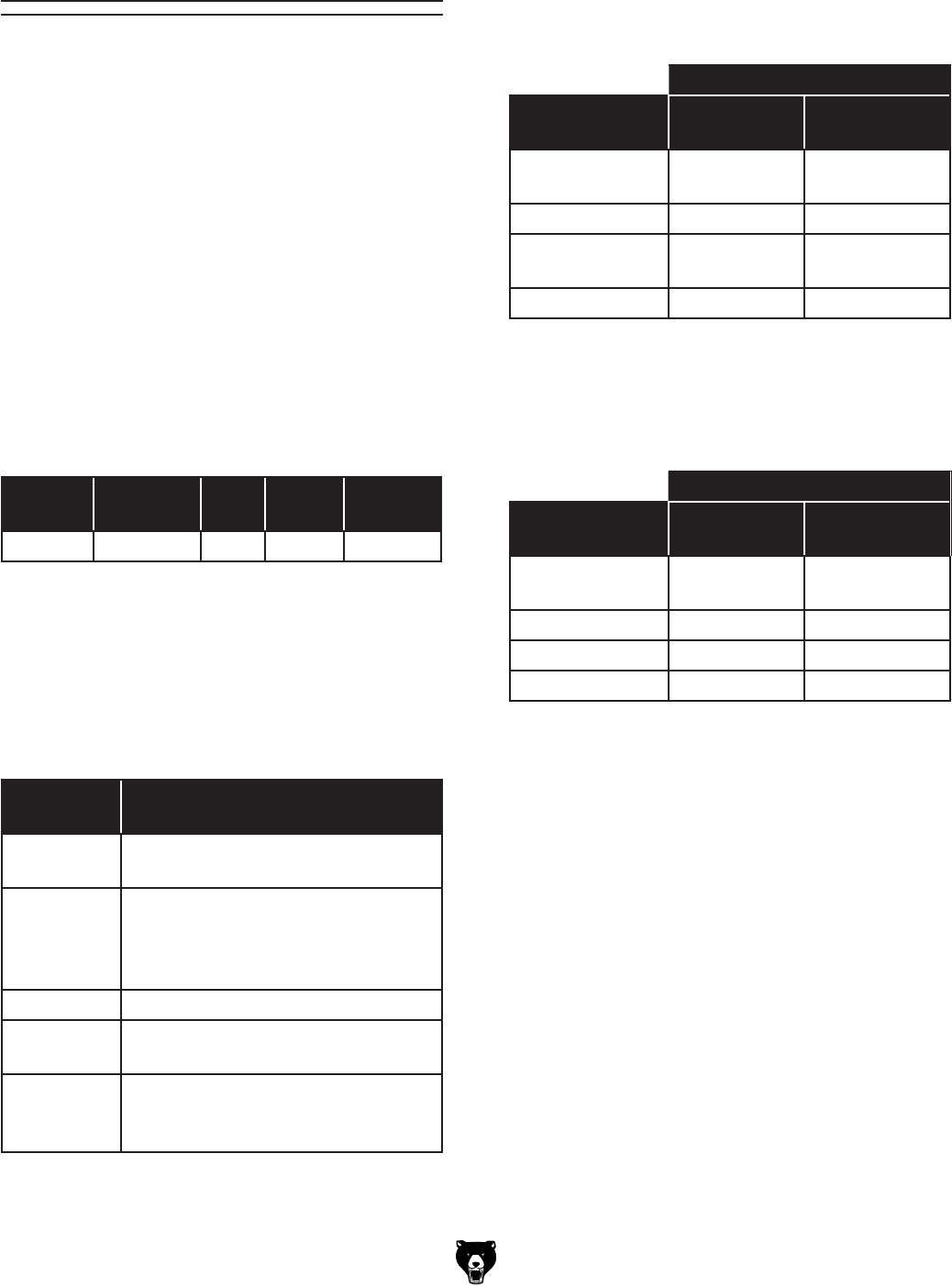

An example of the basic format for wheel number-

ing is shown below. The wheel in this example is

a “36A60LV”.

Prefix

Abrasive

Type

Grit

Size

Grade

Bond

Type

36 A 60 L V

Results

Operation

Consideration

Coarse Grit

(10–46)

Fine Grit

(54–180)

Material

Removal

Increased Decreased

Surface Finish Rough Smooth

Workpiece

Hardness

Soft Hard

Width of Cut Wide Narrow

The prefix is a manufacturer-specific designation

and will vary depending on the manufacturer.

Use the charts below as a basic wheel selection

outline for most grinding operations.

Abrasive Type

Abrasive

Type

Application

A

Aluminum Oxide. For grinding

common steel.

WA

White Aluminum Oxide. For

grinding harder metals (heat

treated steel, carbon steel, alloy

steel, etc.).

H For grinding high speed steel.

C

Silicon Carbide. For grinding

cast iron and non-ferrous metals.

CG

Ceramic Grain. For extremely

hard metals, such as tungsten

carbide.

Grit Size

The ideal grit for an operation depends on a

number of considerations. Use the table below to

choose a grit suitable for your desired results.

Grade

The grade of a wheel is an indicator of its hard-

ness based on an alphabetical scale in which A is

the softest and Z is the hardest.

Wheel Hardness

Operation

Consideration

Soft

A–M

Hard

N–Z

Workpiece

Hardness

Hard Soft

Width of Cut Wide Narrow

Feed Rate Slow Fast

Wheel Speed Fast Slow

Wheel Selection

Bond Type

This refers to the type of bonding material used to

hold the abrasive material. Most general purpose

wheels will have a V indicating vitrified clay is

used, providing high strength and good porosity.

The other most common is B where synthetic res-

ins are used. These are used to grind cemented

carbide and ceramic materials.