TROUBLESHOOTING & REPAIR

F-80 F-80

RANGER 305D

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

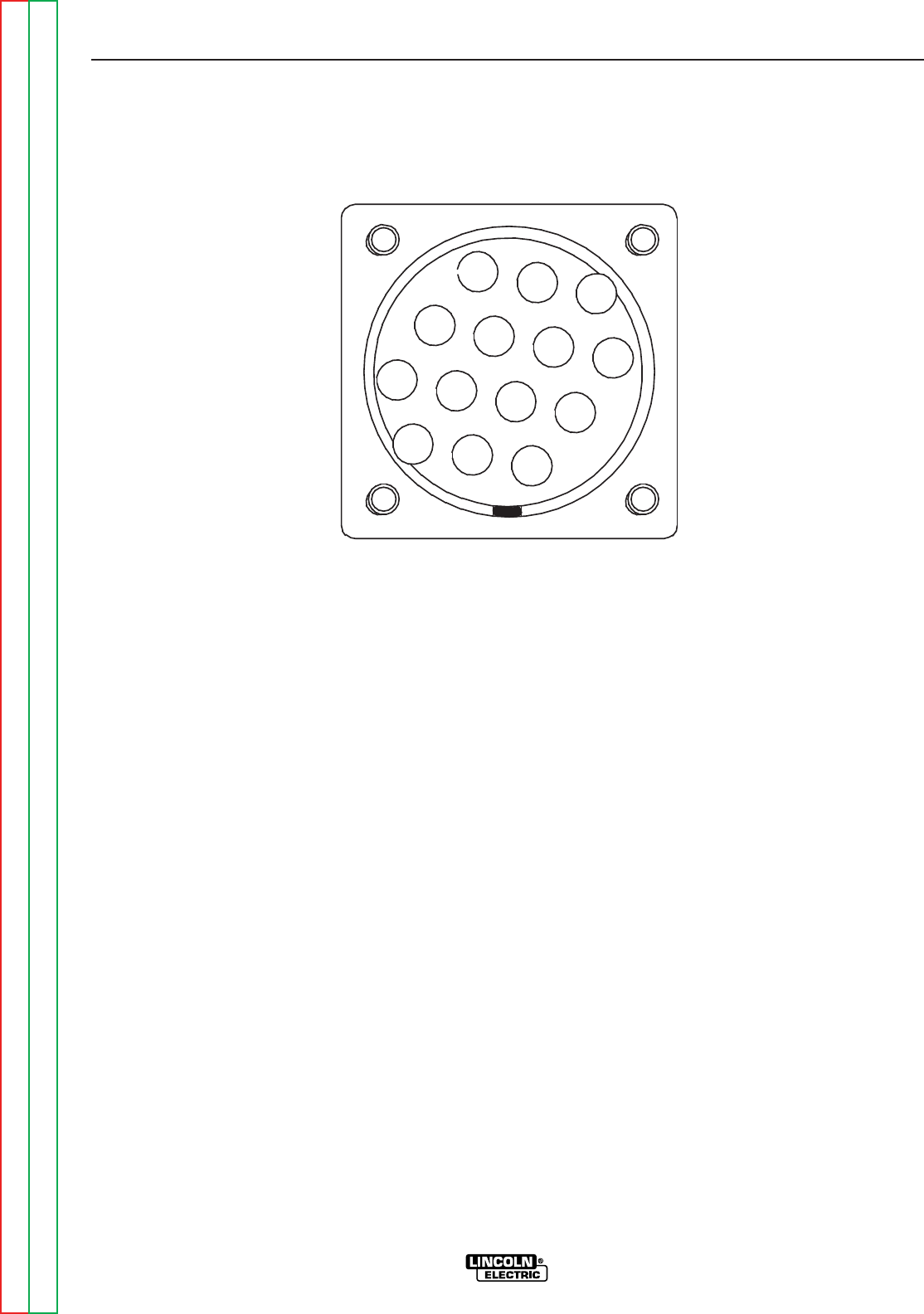

REMOTE RECEPTACLE RESISTANCE TEST (continued)

FIGURE F.18

AMPHENOL 1

E

C

D

A

B

L

K

J

M

N

F

G

H

I

TEST PROCEDURE

1. Turn the machine off.

2. Perform the Case Cover Removal

Procedure.

3. Make sure that there are no devices of any

kind plugged into either Amphenol recepta-

cles.

4. Remove Molex plug P1 from the control PC

board, see Control Inner-Connection

Diagram. Examine the Molex plug and the

receptacle on the control PC board for dirt,

corrosion, damaged or out-of-position pins.

Repair or replace any damaged components.

Position the P1 plug so it can not make elec-

trical contact with any other conductor or

chassis ground.

5. Perform the following resistance tests shown

in the following table. Be very careful not to

damage or spread any of the connection pins

in the Amphenol receptacle. See Table F.4.

6. If the measured resistance does not meet

values specified, check for damage, dirt or

moisture contamination in the Amphenol

receptacles and the P1 Molex plug. Check

for damaged or grounded wiring.

7. If the resistance values are found to be too

low, due to contaminated electrical compo-

nents in the Amphenol harness assembly.

Try removing the contamination and drying

the components completely. If the resistance

values are still too low, replace the Amphenol

harness assembly.

8. If the values are incorrect for the last two

tests in the table, (Pin C to Pin D) check the

welding terminal switch and the wiring con-

nected to that switch. See the wiring dia-

gram. Repair any faulty connections or

replace the switch if necessary.

9. Plug P1 back into the Control Pc board.

10. Perform the Case Cover Replacement

Procedure.