CONNECTION OF THE LN-25 TO THE

RANGER 305D “ACROSS THE ARC”

WITH K857 REMOTE CONTROL

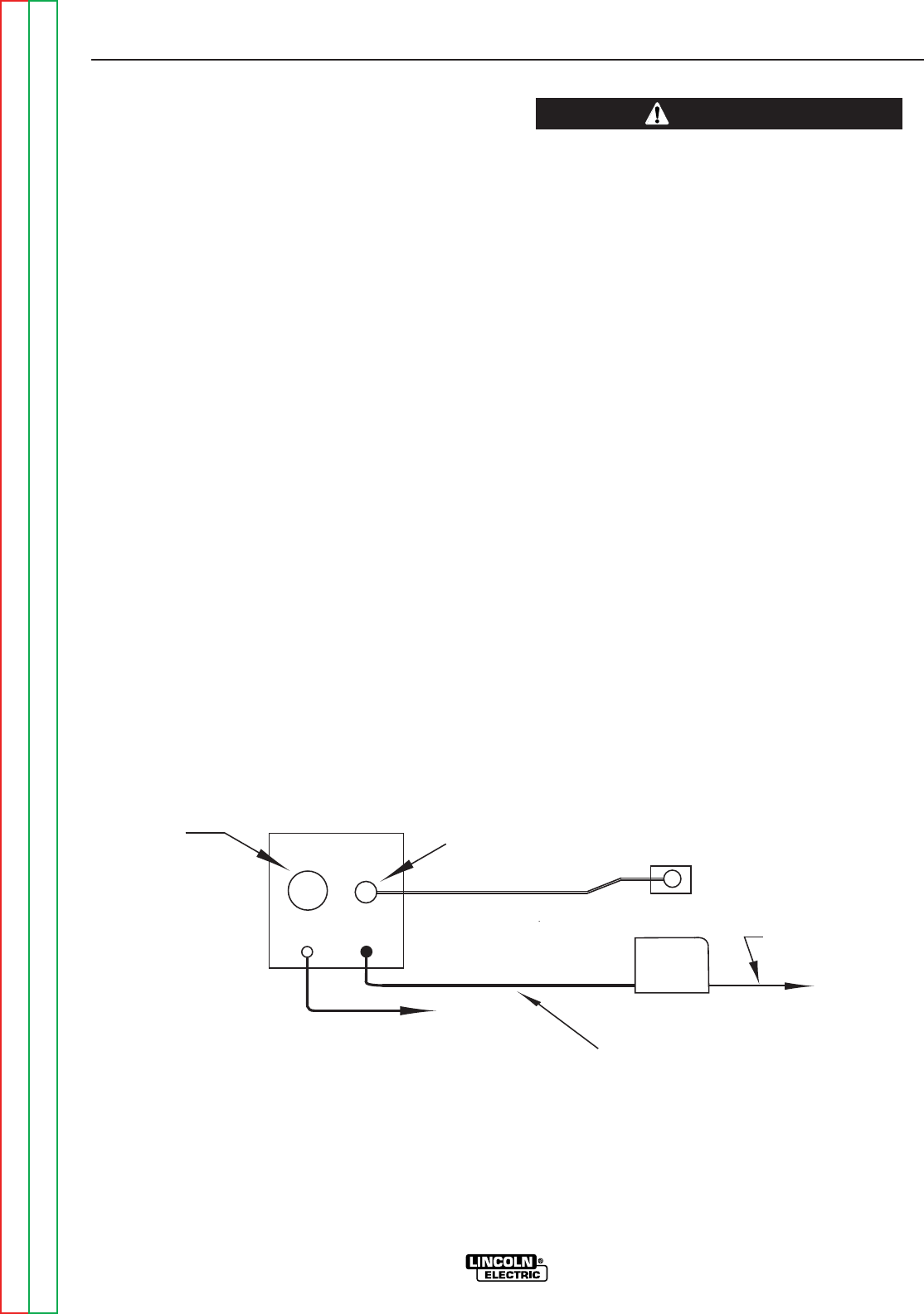

(SEE FIGURE C.4.)

1. Shut the welder off.

2. Connect the electrode cable from the LN-25 to the

“-” terminal of the welder. Connect the work cable

to the “+” terminal of the welder.

NOTE: Welding cable must be sized for current and

duty cycle of application.

NOTE: Figure C.4 shows the electrode connected for

negative polarity. To change polarity, shut the welder

off and reverse the electrode and work cables at the

Ranger 305D output terminals.

3. Connect the K857 Remote Control to the 6-pin

amphenol on the Ranger 305D.

4. Attach the single lead from the LN-25 to the work

using the spring clip on the end of the lead. This

is only a sense lead - it carries no welding current.

5. Place the “IDLER” switch in the “AUTO” or “HIGH”

position, as desired.

If you are using an LN-25 without an internal contactor,

the electrode will be “HOT” when the Ranger 305D is

started.

------------------------------------------------------------------------

6. Set the “MODE” switch to “CV-WIRE.”

7. Set the “WELD TERMINALS” switch in the “WELD

TERMINALS ON” position.

8. Set the “VOLTMETER” switch to “+” or “-” depend-

ing on the polarity chosen.

9. Adjust the wire feed speed at the LN-25 and adjust

the welding voltage with the K857 if optional

remote control is used.

9. Adjust the ARC control to “0” initially and adjust to

suit.

ACCESSORIES

C-6 C-6

RANGER 305D

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CAUTION

+

-

TO WORK

14-PIN

AMPHENOL

6-PIN

AMPHENOL

OPTIONAL K857

REMOTE CONTROL

ELECTRODE CABLE

LN-25

WIRE FEEDER

TO WORK

WORK CLIP LEAD

FIGURE C.4 - Ranger 305D/LN-25 ACROSS THE ARC

CONNECTION DIAGRAM WITH K857 REMOTE CONTROL